Caution: When drilling into any vehicle surface,

make sure that the area is free from any electrical wires,

fuel lines, vehicle upholstery, etc. that could be damaged.

Specications:

Size: 7945:6.0”dia.x4.8”high

7950:6.0”dia.x6.8”high

Weight: approx. 3 lbs.

Input Voltage: 12-48 VDC system

Input Current: 0.5A @ 12.8 VDC

Maximum power consumption: 6.4 Watts

Temp. Range: -30°C to +50°C

Carefullyremovethebeaconandplaceitonaatsurface.Examine

the unit for transit damage, and locate all parts. If damage is found,

or parts are missing, contact the transit company or ECCO. Do not

use damaged or broken parts.

Permanent Mounting:

SelectthedesiredlocationonaatsurfacefortheLEDbeaconto

bemounted.Thevisibilityoftheashandeaseofwiringaccess

should be taken into consideration in the selection of the mounting

location.

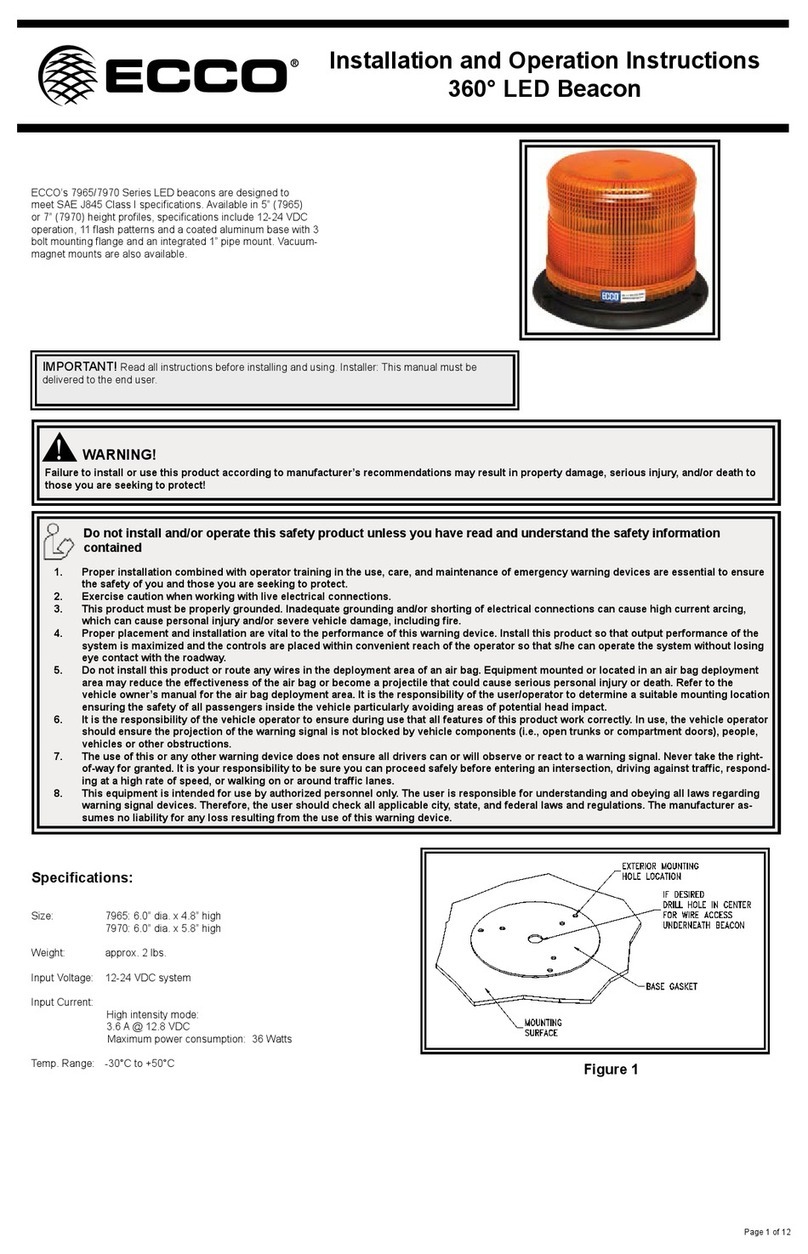

1. Using the base gasket as a template, mark the three mount-

ingholelocations(seeFigure1).

2. Drilltheholesusinga7/32”drillsize.

3. AfourthholemaybedrilledforwireaccessasshowninFig-

ure 1, or the wires may be routed through the slot in the base

for external access.

4. Connectthepowerwiresasshowninthewiringsection(see

Figure3).

5. Mount the beacon with #8 hardware.

Pipe Mounting:

The7945&7950seriesbasecomeswith1”NPTthreadsforpipe

mounting.

Figure 1

Temporary Mounting, Vacuum-Magnet Mount:

The 7945 & 7950 series beacons are available as vacuum-magnet

mount(7945X-VM&7950X-VM)units.TheVacuum-MagnetMount

feature includes a suction cup on the bottom of the beacon, with a

magnet inside of the suction cup, for a secure, temporary mount. The

beacon should be placed in the center of the roof where the least

amount of curvature occurs. Before installing, make sure there is

no debris on the bottom of the beacon or on the roof of the vehicle,

which could reduce the holding power of the suction cup and mag-

net. Place and remove the beacon without sliding to avoid scratching

the paint on the vehicle. After placement, the beacon should adhere

rmlytothesurface.Iftheunitslidesormoveseasily,aproperin-

stallation has not been obtained. To release the vacuum, lift the tab

toreleasetheairlock(seeFigure2).ToprotecttheVacuum-Magnet

Mount assembly, return beacon to the box when not in use. Do not

attempt to attach the beacon to an ice-covered surface.

920-0220-00 Rev. D Page 2 of 4

Important! This unit is a safety device, and it must be

connected to its own seperate, fused power point to as-

sure its continued operation should any other electrical

accessory fail.

WARNING!

Maximum recommended vehicle speed for safe operation

using the Vacuum Mount model is 65 mph (104 km/h), when tted

to the center of a vehicle roof of steel construction. Higher speeds

could cause the mount to fail, resulting in the beacon ying off

of the vehicle, which could cause damage to other vehicles, and

injury or death to the passengers. The vacuum-magnet mount is not

intended as a permanent mounting for the beacon. The vacuum-

magnet mount unit must be mounted on a at smooth magnetic

surface (i.e. no berglass, ribbed style roofs, etc.). Insure that the

magnet is kept clean.

Figure 2

Installation & Mounting: