Erbe IES 3 User manual

2023-0180116-951_V23921

SERVICE MANUAL

IES 3

V 1.0.x

SERVICE MANUAL

IES 3

Registered trademarks of Erbe Elektromedizin GmbH: autoCUT®, BiCision®, BiClamp®, CleverCap®, CleverView®,

endoCUT®, endoCOAG®, Erbe®, erbe power your performance.®, ERBECRYO®, ERBEFLO®, ERBEJET®, ERBOKRYO®,

eTip®, FiAPC®, forcedCOAG®, HybridKnife®, HybridTherm®, HYDRON®, IES VACpen®, KYRON®, NESSY®, NESSY Ω®,

PLURA®, preciseAPC®, Preflow®, pulsedAPC®, ReMode®, softCOAG®, sprayCOAG®, swiftCOAG®, thermoSEAL®, TriSect

rapide®, twinCOAG®, VIO®.

Registered trademark of Erbe, USA, Inc.: CleverCap®.

For an up-to-date list of all Erbe trademarks, please visit www.erbe-med.com/IP.

All rights to this manual, in particular rights of duplication, dissemination and translation, are reserved. No part of this man-

ual may be reproduced in any form (by photocopying, microfilming or other methods) or processed, duplicated or dissem-

inated by the use of electronic systems without the written consent of Erbe Elektromedizin GmbH.

The information contained in this manual may be amended or supplemented without prior notice and represents no obli-

gation on the part of Erbe Elektromedizin GmbH.

The display illustrations in these instructions may deviate from one another depending on the software version. The display

illustrations used in these instructions are generally taken from the latest software version. Display illustrations from older

software versions will only be used if necessary due to service activities; these will be specifically labeled.

Printed by Erbe Elektromedizin

Printed in Germany

Copyright © Erbe Elektromedizin GmbH, Tübingen 2023

5 / 32

Table of Contents

80116-951_V23921

2023-01

Table of Contents

1Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Classification of the safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Knowledge of the User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Protection from the risk of electric shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrostatically sensitive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Liability and warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controls at the front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controls at the rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4Device settings and service menu . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Device settings overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview: "Service" menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5Remedying malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ERROR list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6Maintenance and servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Who is allowed to perform servicing and maintenance work? . . . . . . . . . . . . . 27

What is a technical safety check? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How often does a technical safety check have to be performed?. . . . . . . . . . . 27

Technical safety check – step by step. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Testing and measuring equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

User manual and visual inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical safety checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Performance tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pressure test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Filter recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table of Contents

6 / 32

80116-951_V23921

2023-01

7 / 32

1 •Safety information

80116-951_V23921

2023-01

CHAPTER 1

Safety information

Classification of the safety information

Knowledge of the User Manual

The User Manual for this unit constitutes an integral part of this Service

Manual. For performing servicing activities it is assumed that the reader

has knowledge of the User Manual, especially procedures for installation,

putting into operation, and handling.

Protection from the risk of electric shock

WARNING! The WARNING! safety indication refers to a risk of personal injury.

CAUTION! The CAUTION! safety indication refers to a risk of damage to property.

ATTENTION! The ATTENTION! safety indication refers to a risk which can cause

equipment to become unserviceable.

IMPORTANT! The IMPORTANT! designation indicates application information and

other particularly important information.

WARNING! The supply voltage must match the voltage specified on the rating

plate. Connect the unit / the equipment cart to a properly installed

grounded outlet. Only use the Erbe power cord or an equivalent power

cord for this purpose. The power cord must bear the national test sym-

bol.

For safety reasons, multiple outlets and extension cords should not be

used. If their use is unavoidable, they also must be provided with proper

grounding.

1 •Safety information

8/ 32

80116-951_V23921

2023-01

Electrostatically sensitive components

Liability and warranty

WARNING! Unplug the power cord from the outlet before exchanging parts of the

unit or cleaning it.

WARNING! Do not plug a wet power cord into the unit or into an outlet.

WARNING! Do not touch any unprotected wires or conductive surfaces while the

unit is opened and under voltage.

WARNING! Blown line fuses may only be replaced by a competent technician. Only

replacement fuses of the rating specified on the unit's name plate may

be used. Before resuming operation on the unit have a performance

test conducted by a competent technician (see Service Manual, chapter

"Maintenance and servicing", section "Performance tests").

CAUTION! This unit contains electrostatically sensitive components. Work at an

anti-static workplace while repairing the unit. Wear a grounding arm-

band while working with electrostatically sensitive components. Hold

the circuit boards by their non-conducting corners. Use an anti-static

container for transporting electrostatically sensitive components and

the circuit boards.

ATTENTION! Adjustments, tests, modifications, maintenance and repair work may

only be performed by Erbe or persons trained by Erbe. If the work is not

performed by trained persons, Erbe accepts no liability and warranty

rights become void.

It is recommended that the technical safety check also be performed by

Erbe or persons trained by Erbe.

ATTENTION! Only use original Erbe spare parts. The manufacturer accepts no liability

and the warranty rights becomes void if original spare parts are not

used.

9 / 32

2 •Controls

80116-951_V23921

2023-01

CHAPTER 2

Controls

Controls at the front

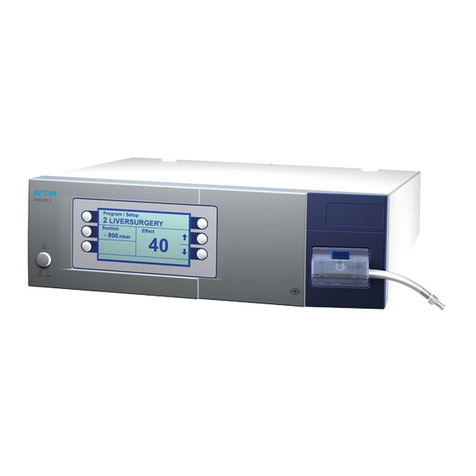

Fig. 2-1

IMPORTANT! This chapter contains an overview of the controls of the unit(s). The rel-

evant User Manual for the unit(s), knowledge of which is assumed for

servicing work, provides detailed information about how to use the

unit(s).

1

2

3

4

1Power Switch

2Main filter cartridge release

3Main filter cartridge with connection for suction accessories

4Touchscreen

2 •Controls

10 / 32

80116-951_V23921

2023-01

Controls at the rear

Fig. 2-2

1 Power supply module with fuses

2Exhaust slot with fixing holes for suction element

3Socket for automatic activation device

(the socket is fitted with a cover ex works, which is not shown in the im-

age above)

4ECB socket (Erbe Communication Bus)

5Footswitch socket

6Potential equalization terminal

7Ventilation slot for cooling

(there are also ventilation slots for cooling on the underside of the de-

vice, which is not shown in the image above)

1

2

3456

7

11 / 32

3 •Technical Data

80116-951_V23921

2023-01

CHAPTER 3

Technical Data

Power connection

Rated supply voltage 100–240 V AC (±10%)

Rated supply frequency 50 Hz / 60 Hz

Line current max. 3 A

Power consumption max. 300 watt / standby: 12 watt at 230 V; 12 watt

at 115 V

Terminal for grounding (potential equalization) yes

Power fuses T 4 A H / 250 V

Operating mode

Continuous operation

Unit data

Filter specifications ULPA 15 as per EN 1822-3:2011 and EN 1822-

5:2011.

Satisfies the requirements of ISO 16571 – Smoke

evacuation units.

Noise emission At 60% suction capacity ≤49 dB(A) as per DIN EN

ISO 3744

At max. suction capacity ≤59 dB(A) as per DIN EN

ISO 3744

Max. suction capacity 300 l/min (unit regulates itself)

Filter life

depending on the mode setting and suction capacity

in the OPEN mode 40 hours at 30% suction capacity

32 hours at 60% suction capacity

25 hours at 100% suction capacity

in the LAP mode 80 hours at 30% suction capacity

60 hours at 60% suction capacity

40 hours at 100% suction capacity

3 •Technical Data

12 / 32

80116-951_V23921

2023-01

Dimensions and weight

Width x height x depth 205 x 280 x 404 mm

Weight (with main filter cartridge) 9.7 kg

Display size 5.7 inch

Ambient conditions for transport and storage of unit

Temperature -29 °C to +60 °C

Relative humidity 15%–85%

Air pressure 54 kPa–106 kPa

Ambient conditions for operation of unit

Temperature +10 °C bis +40 °C

Relative humidity 15%–85%, non-condensing

Air pressure 54 kPa–106 kPa

Max. operating altitude 5000 m AMSL

Acclimatizing

If the unit has been stored or transported at temperatures below +10 °C or above +40 °C, the unit will

require approx. 3 hours to acclimatize at room temperature.

Standards

Classification according to Regulation (EU) 2017/745

I

Classification according to MDD 93/42/EEC I

Protection class as per EN 60 601-1 I

Type as per EN 60 601-1 CF

ISO 16571 Medical devices – Systems for evacuation of plume

generated by medical devices

13 / 32

4 •Device settings and service menu

80116-951_V23921

2023-01

CHAPTER 4

Device settings and service menu

General information

This unit has two levels for changing settings

Device settings The device can also be adapted for individual use via the device settings

level and also reset to the factory settings. You can also view interesting

information on the device, such as the serial number and software status

here. This level is accessible for users and service personnel.

"Service" menu The "Service" menu offers test programs, various lists for fault analysis

and other unit information relevant for service. It is only intended for ser-

vice personnel.

Device settings overview

Accessible to users and service personnel.

Accessing device settings 1. Touch (the screen for the OPEN or LAP settings opens).

2. Touch (the screen for the device settings opens).

Setting Available from Description

Brightness V 1.0.x Set the touchscreen brightness.

Volume V 1.0.x Set the device volume.

Filter status V 1.0.x Type of remaining filter display:

Percent (%)

Duration (e.g. 29h50 [min.])

Start pro-

gram

V 1.0.x Start screen selection:

OPEN

LAP

Last mode used

Language V 1.0.x Self-explanatory.

Factory reset V 1.0.x Resets the device to the factory settings.

4 •Device settings and service menu

14 / 32

80116-951_V23921

2023-01

Connections V 1.0.x Displays the connection between the IES 3 and:

Electrosurgical unit

Footswitch

Automatic Activation Device

= connected

x = not connected

Information V 1.0.x Displays the serial number, the software status of the IES 3 and vari-

ous assemblies.

Setting Available from Description

15 / 32

4 •Device settings and service menu

80116-951_V23921

2023-01

Overview: "Service" menu

Only accessible for service personnel. Password-protected.

Call up Service menu 1. Touch (the screen for the OPEN or LAP settings opens).

2. Touch (the screen for the device settings opens).

3. Touch .

4. Enter service PIN 4373 and confirm by pressing (the Ser-

vice menu is called up).

IMPORTANT! Regardless of the language setting selected on the unit, the "Service"

menu is only available in English.

Setting Available

from Description

Display orientation V 1.0.x Rotates the device’s display:

portrait

landscape

Error list V 1.0.x Stores errors and incidents, max. 20 entries

Audio test V 1.0.x Test programs are described in the repair manual.

IMPORTANT! Erbe explicitly warns against using the test programs

listed here without accurate knowledge and training.

Display test V 1.0.x

Electronics test V 1.0.x

Fan test V 1.0.x

Pressure test V 1.0.x

Turbine test V 1.0.x

Touch test V 1.0.x

Translations test V 1.0.x

4 •Device settings and service menu

16 / 32

80116-951_V23921

2023-01

17 / 32

5 •Remedying malfunctions

80116-951_V23921

2023-01

CHAPTER 5

Remedying malfunctions

Safety information

ERROR list

ERROR list as at: 02/19

ATTENTION! Adjustments, technical tests, modifications, maintenance and repair

work may only be performed by Erbe or persons trained by Erbe. If the

work is not performed by trained persons, Erbe accepts no liability and

warranty rights become void.

Error code Description Action

2-86-001 The sensor values are outside the per-

missible range.

Vacuum too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-86-002 The sensor values are outside the per-

missible range.

Vacuum too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-86-004 The sensor values are outside the per-

missible range.

Temperature too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-86-008 The sensor values are outside the per-

missible range.

Temperature too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-87-001 The voltage values are outside the per-

missible range.

Supply voltage 3 V too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-87-002 The voltage values are outside the per-

missible range.

Supply voltage 3 V too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-87-004 The voltage values are outside the per-

missible range.

Supply voltage 24 V too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

5 •Remedying malfunctions

18 / 32

80116-951_V23921

2023-01

2-87-008 The voltage values are outside the per-

missible range.

Supply voltage 24 V too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-001 The motor driver is faulty. Gate-Source.

VGS_LC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-002 The motor driver is faulty. Gate-Source.

VGS_HC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-004 The motor driver is faulty. Gate-Source.

VGS_LB

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-008 The motor driver is faulty. Gate-Source.

VGS_HB

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-010 The motor driver is faulty. Gate-Source.

VGS_LA

Restart the unit. If the error occurs again,

notify Erbe Service.

2-88-020 The motor driver is faulty. Gate-Source.

VGS_HA

Restart the unit. If the error occurs again,

notify Erbe Service.

2-89-001 The motor driver is faulty.

CPUV

Restart the unit. If the error occurs again,

notify Erbe Service.

2-89-002 The motor driver is faulty.

OTW

Restart the unit. If the error occurs again,

notify Erbe Service.

2-89-004 The motor driver is faulty.

SC_OC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-89-008 The motor driver is faulty.

SB_OC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-89-010 The motor driver is faulty.

SA_OC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8A-001 The motor driver is faulty. Drain-Source.

VDS_LC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8A-002 The motor driver is faulty. Drain-Source.

VDS_HC

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8A-004 The motor driver is faulty. Drain-Source.

VDS_LB

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8A-008 The motor driver is faulty. Drain-Source.

VDS_HB

Restart the unit. If the error occurs again,

notify Erbe Service.

Error code Description Action

19 / 32

5 •Remedying malfunctions

80116-951_V23921

2023-01

2-8A-010 The motor driver is faulty. Drain-Source.

VDS_LA

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8A-020 The motor driver is faulty. Drain-Source.

VDS_HA

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8B-001 The motor driver is faulty.

OTSD

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8B-002 The motor driver is faulty.

UVLO

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8B-004 The motor driver is faulty.

GDF

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8B-008 The motor driver is faulty.

VDS_OCP

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8B-010 The motor driver is faulty.

FAULT

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-001 The current values are outside the per-

missible range.

Turbine 1 current too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-002 The current values are outside the per-

missible range.

Turbine 2 current too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-004 The current values are outside the per-

missible range.

Turbine 1 peak current too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-008 The current values are outside the per-

missible range.

Turbine 2 peak current too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-010 The current values are outside the per-

missible range.

Turbine 1 current too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-020 The current values are outside the per-

missible range.

Turbine 2 current too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8C-040 The current values are outside the per-

missible range.

Turbine 1 peak current too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

Error code Description Action

5 •Remedying malfunctions

20 / 32

80116-951_V23921

2023-01

2-8C-080 The current values are outside the per-

missible range.

Turbine 2 peak current too high.

Gerät neu starten. Tritt der Fehler erneut

auf => Erbe-Service informieren.

2-8D-001 The speed of the turbines or of the fan is

outside of the permissible range.

Turbine 1 speed too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8D-002 The speed of the turbines or of the fan is

outside of the permissible range.

Turbine 2 speed too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8D-004 The speed of the turbines or of the fan is

outside of the permissible range.

Fan speed too low.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8D-010 The speed of the turbines or of the fan is

outside of the permissible range.

Turbine 1 speed too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8D-020 The speed of the turbines or of the fan is

outside of the permissible range.

Turbine 2 speed too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8D-040 The speed of the turbines or of the fan is

outside of the permissible range.

Speed fan too high.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-001 The internal communication does not

correspond to the protocol.

Invalid parameters.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-002 The internal communication does not

correspond to the protocol.

Übertragungsfehler (Parity, Noise, Frame,

Overrun, DMA transfer, Busy).

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-004 The internal communication does not

correspond to the protocol.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-008 The internal communication does not

correspond to the protocol.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-010 The internal communication does not

correspond to the protocol.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-020 The internal communication does not

correspond to the protocol.

Restart the unit. If the error occurs again,

notify Erbe Service.

2-8E-040 The internal communication does not

correspond to the protocol.

Restart the unit. If the error occurs again,

notify Erbe Service.

Error code Description Action

Other manuals for IES 3

1

Table of contents

Other Erbe Medical Equipment manuals

Erbe

Erbe ICC 200 User manual

Erbe

Erbe ICC 50 User manual

Erbe

Erbe ICC 350 User manual

Erbe

Erbe ESM 2 User manual

Erbe

Erbe VIO 300 D User manual

Erbe

Erbe 20321-040 User manual

Erbe

Erbe 20134-004 Operating instructions

Erbe

Erbe 20191-075 Operating instructions

Erbe

Erbe 20193-008 Operating instructions

Erbe

Erbe VIO 300 D User manual

Erbe

Erbe APC 300 User manual

Erbe

Erbe VIO 300 D User manual

Erbe

Erbe VIO 3 User manual

Erbe

Erbe 20195-080 User manual

Erbe

Erbe APC 2 User manual

Erbe

Erbe 20193-008 Operating instructions

Erbe

Erbe 20150-020 Operating instructions

Erbe

Erbe VIO 300 D User manual

Erbe

Erbe VIO 3 User manual

Erbe

Erbe IES 3 User manual