Leuze electronic BCL 40 3

Leuzeelectronic Figures and tables

Figure 3.1: Possible combinations of the BCL 40 / MA 10...........................................................12

Figure 3.2: Networking possibilities using the multiNet plus.........................................................13

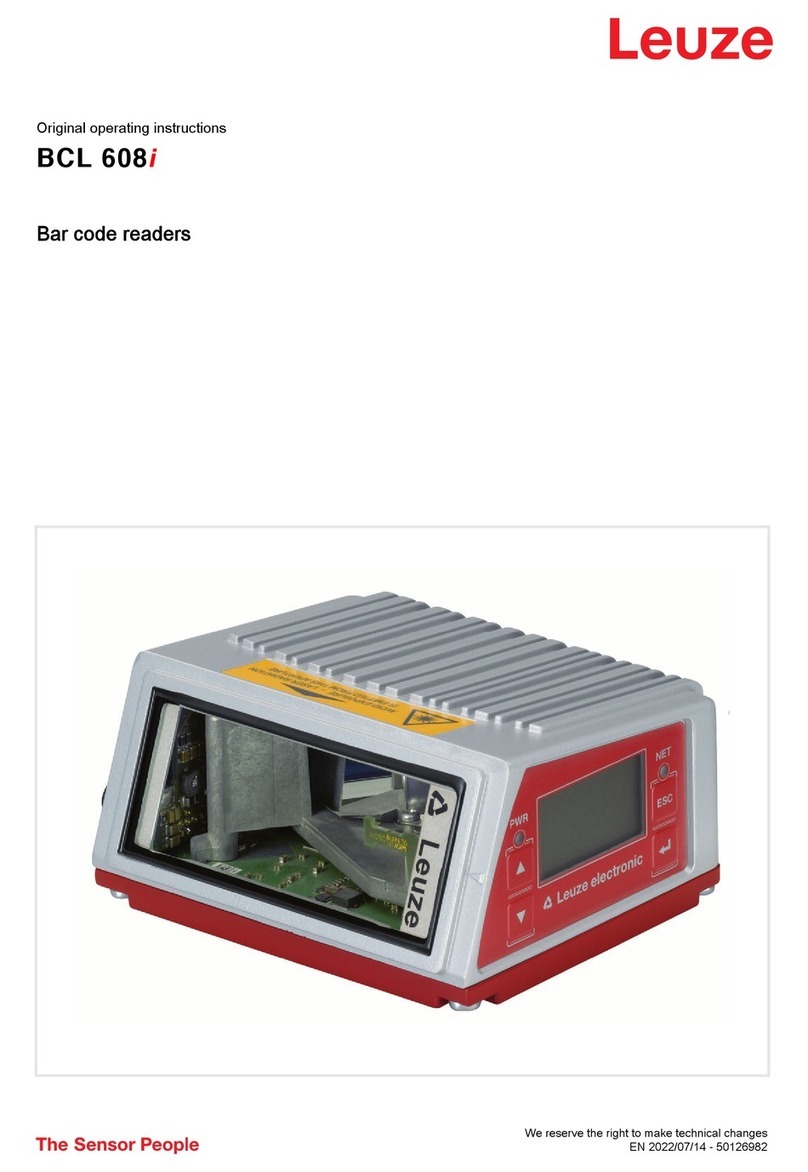

Figure 3.3: BCL 40/device construction........................................................................................14

Figure 3.4: Connector unit MA 10.................................................................................................15

Table 4.1: General Specifications BCL 40 Standard Version......................................................17

Table 4.2: General Specifications BCL 40 with Heater...............................................................17

Table 4.3: General Specifications MA 10....................................................................................18

Figure 4.1: Dimensioned drawing BCL 40....................................................................................19

Figure 4.2: Dimensioned drawing MA 10 .....................................................................................19

Figure 4.3: The most important characteristics of a bar code ......................................................20

Table 4.4: Type overview............................................................................................................21

Figure 4.4: Sweep principle of the raster scanner........................................................................21

Figure 4.5: Sweep principle for the line scanner ..........................................................................22

Figure 4.6: Reading curves BCL 40 standard version, optic variants N and M............................23

Figure 4.7: Reading curves BCL 40 standard version, optic variants F and L .............................24

Figure 4.8: Reading curves BCL 40 with heating, optic variants M and L....................................25

Figure 4.9: Reading curves BCL 40 with heating, optic variant F.................................................26

Table 5.1: Accessories/Order Designation BCL 40.....................................................................27

Table 5.2: Accessories/Order Designation MA 10 ......................................................................27

Figure 5.1: Mounting device BT 56...............................................................................................28

Figure 5.2: Mounting device BT 57...............................................................................................28

Figure 5.3: Connection cable between the BCL 40 and MA 10....................................................29

Figure 5.4: Connection cable between BCL 40 "stand alone"......................................................29

Figure 6.1: Device nameplates MA 10 and BCL 40 .....................................................................30

Figure 6.2: Mounting example BCL 40 "stand alone"...................................................................31

Figure 6.3: Mounting example for the combined BCL 40 / MA 10 unit.........................................32

Figure 6.4: Mounting examples for the BCL 40 and MA 10 mounted independently...................33

Figure 6.5: Minimum space requirements for installation.............................................................35

Figure 6.6: Application example "conveyor chain" .......................................................................36

Figure 6.7: Connecting the BCL 40 for "Stand Alone" Operation.................................................38

Figure 6.8: Connection diagram for the Sub D connector plug ....................................................39

Table 6.1: Wiring description BCL 40..........................................................................................40

Figure 6.9: Connecting the BCL 40 with the connector unit MA 10..............................................40

Figure 6.10: Disconnecting the ribbon cable inside the MA 10 ......................................................41

Figure 6.11: Wiring to the terminal strip without screwing down or soldering.................................42

Figure 6.12: Position of the connections for the MA 10..................................................................42

Figure 6.13: Connecting the MA 10 to a RS 485 Host ...................................................................44

Figure 6.14: Connecting the MA 10 to a RS 232 Host ...................................................................44

Figure 6.15: Connecting the MA 10 as active subscriber to a TTY Host........................................45

Figure 6.16: Connecting the MA 10 as passive subscriber to a TTY Host.....................................45

Figure 6.17: Connecting the MA 10 to a RS 422 Host ...................................................................46

Figure 6.18: Connection of the switching input with an external switching voltage........................47

Figure 6.19: Connection of the switching input without an external switching voltage...................47

Figure 6.20: Position of the solder jumpers JL5 and JL6 ...............................................................48

Figure 6.21: Operating voltage used as the switching voltage.......................................................49

Figure 6.22: Switching voltage connected externally (galvanically decoupled)..............................49

Figure 7.1: Control elements of the MA 10...................................................................................51

Figure 7.2: Block diagram storage concept for parameter sets....................................................55