The present operation manual is intended for studying

operation principle, running conditions, storage and technical

maintenance of dual channel detector Astra-621 (hereinafter

“detector”).

The manufacturer reserves the right to make alteration

regarding refinement of the product without prior notification.

All changes will be imported into new edition of the operation

manual.

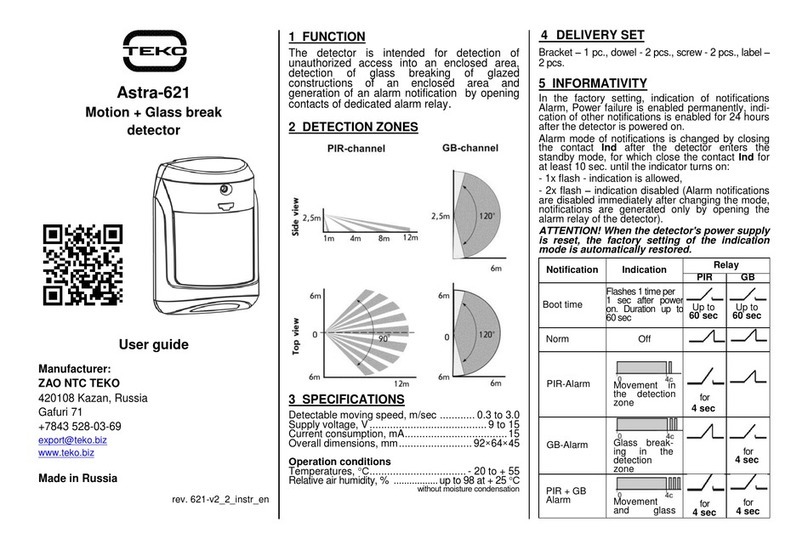

1 Function

1.1 The detector is intended for:

- detection of unauthorized access into an

enclosed area, and generation of an alarm

notification by opening contacts of

dedicated alarm relay;

- detection of glass breaking of glazed

constructions of an enclosed area, and

generation of an alarm notification by

opening contacts of dedicated alarm relay.

Types of protected glass:

- conventional and protected by a polymer

film, thickness from 2.5 mm to 8 mm;

- armored glass, thickness 5.5 mm and 6

mm;

- figure glass, thickness from 4 mm to 7 mm;

- tempered glass, thickness from 4 mm to 6 mm.

Size of glass: area of at least 0.1 m2 (with one side of at least

0.3 m length).

1.2 Power supply of detector is performed from any direct

current source with nominal voltage 12V and pulsation

amplitude not exceeding 0,1V

2 Principle of Operation

2.1 Both IR and Acoustic (AC) detection channels are

activated independently and processed by two separate relay

outputs.

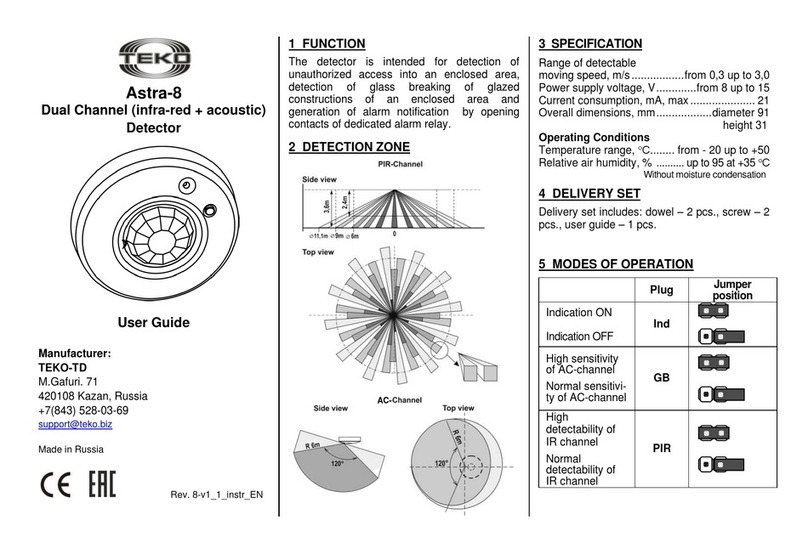

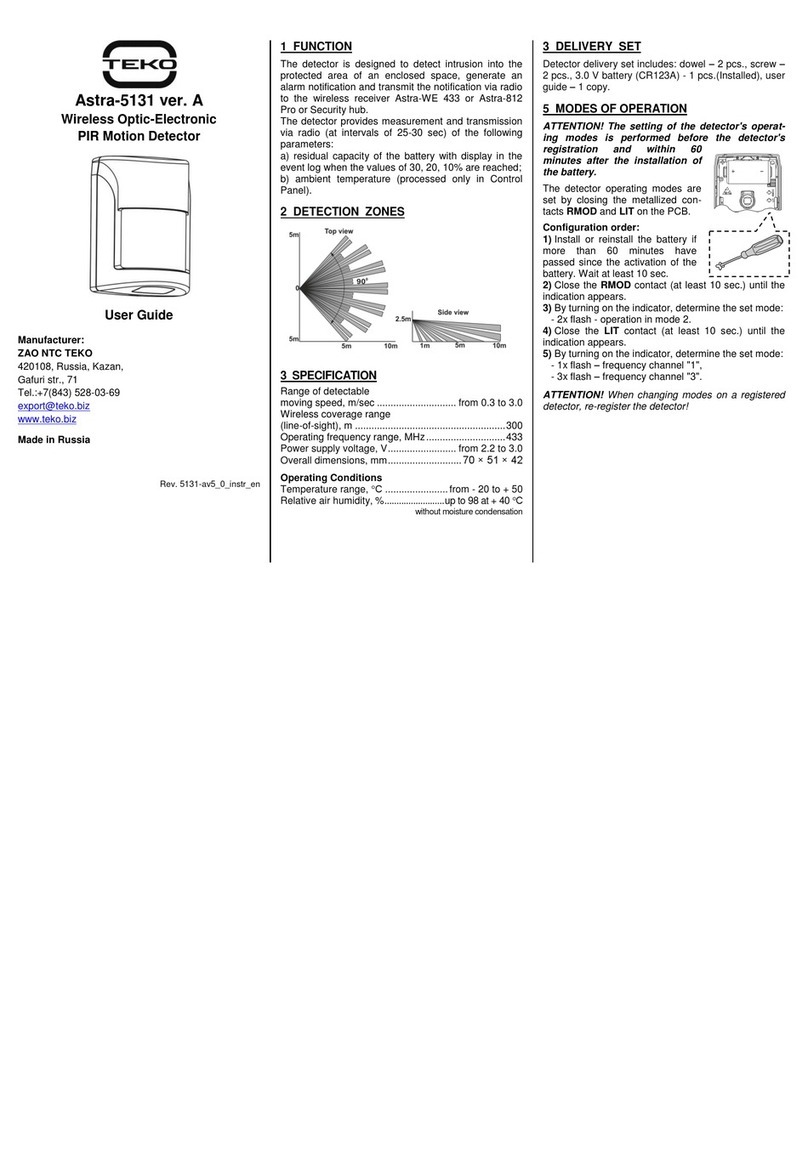

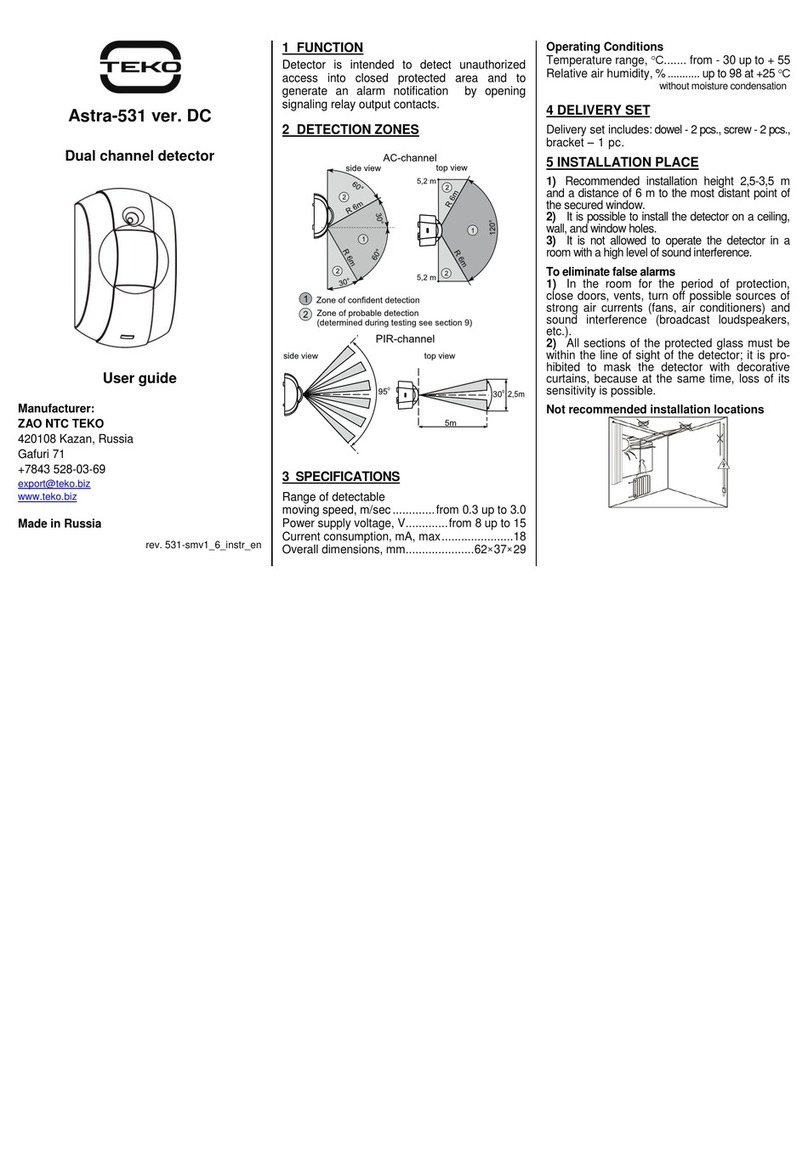

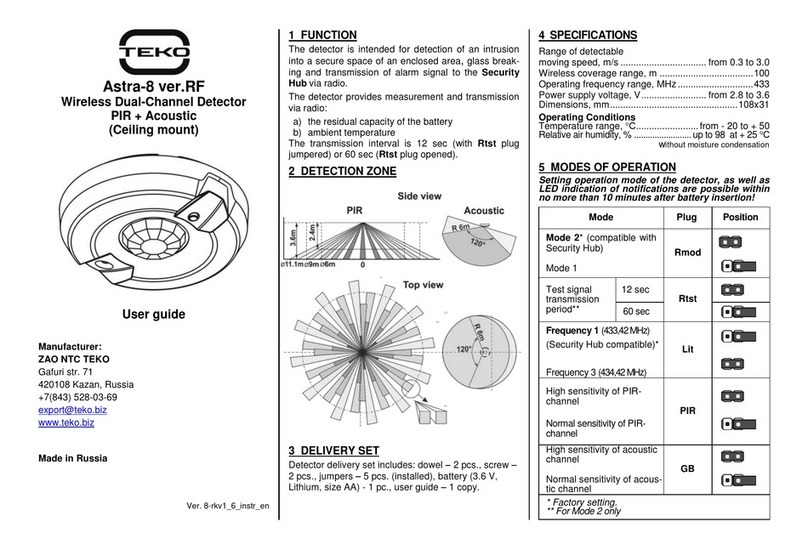

Figure 2

2.2 Operation principle of IR channel is based on registration

of thermal background change of the room occurring on

crossing sensitive zones by a man (Figure 2). Detector

sensitive zones are formed by Fresnel lens and bi-areal

pyroelectric radiation receiver. Pyroelectric receiver sends

electric signal to microcontroller, which in its turn generates an

“Alarm-IR” notification by opening of output circuit of

optoelectronic relay in accordance with pre-set algorithm.

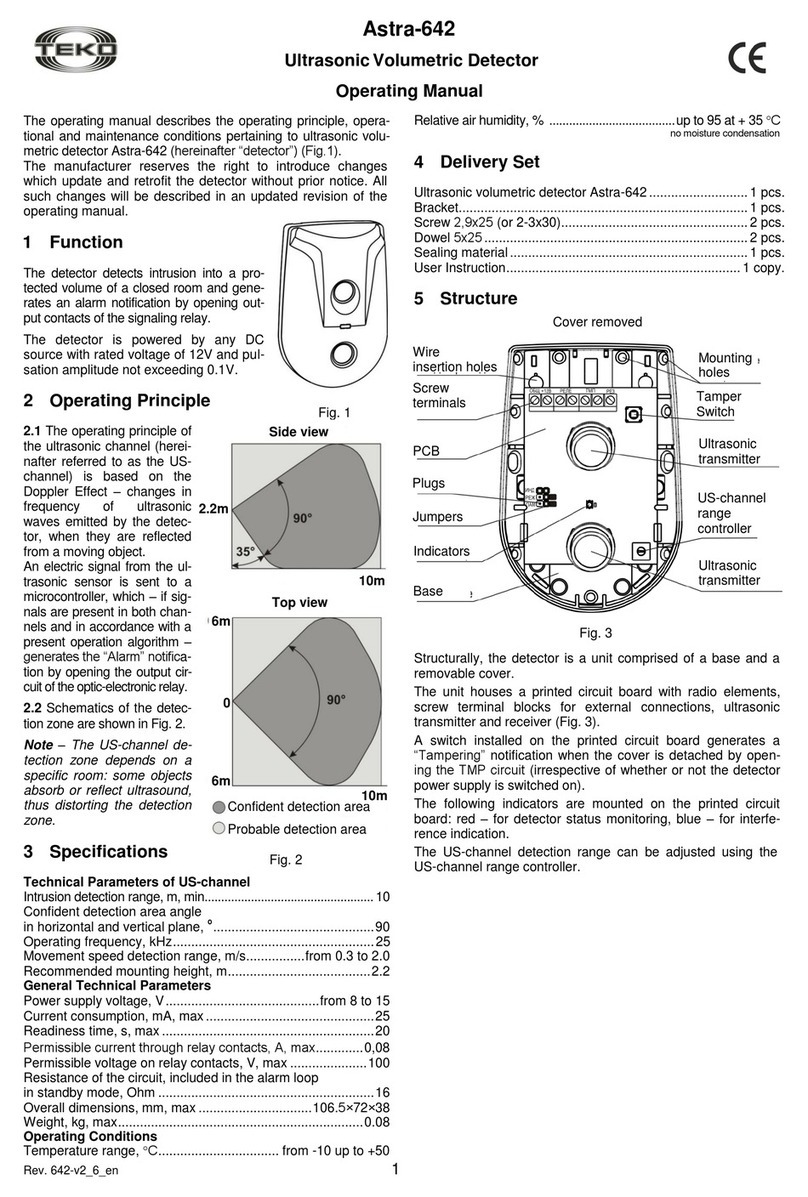

2.3 Sensitive element of AC channel is an electret

microphone with integrated amplifier. Trasmitter modifies

acoustic vibrations into electric signals which are amplified and

sent to microcontroller. Microcontroller processes received

signal and in accordance with preset algorithm takes decision

about presence of glass breakage or low-frequency and high-

frequency interference and generates corresponding

notification.

2.4 To connect the detector to an alarm loop (hardwired

zone) optic-electronic signaling relays are used.

3 Specifications

IR Channel

Detector coverage range, m, not less than...........................12

Dimensions of detection zone with horizontal

viewing angle of 90º, m...................................................12×12

Range of detected movement speed, m/s.......from 0,3 up to 3

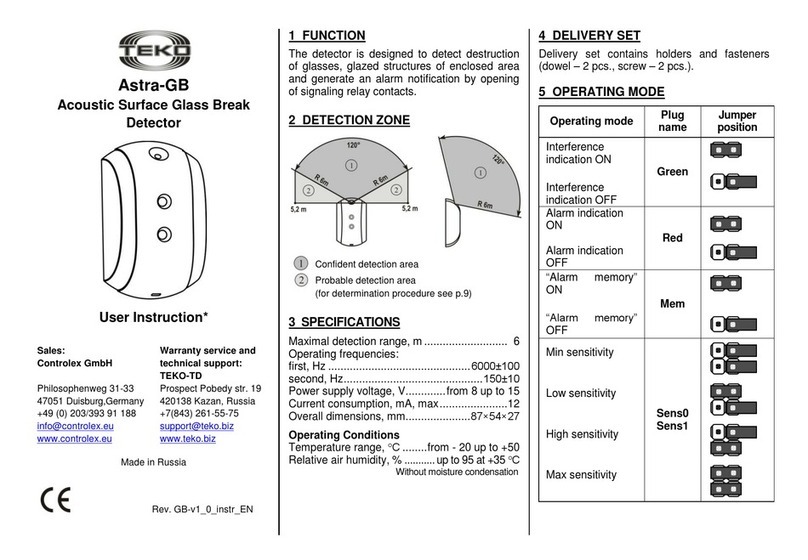

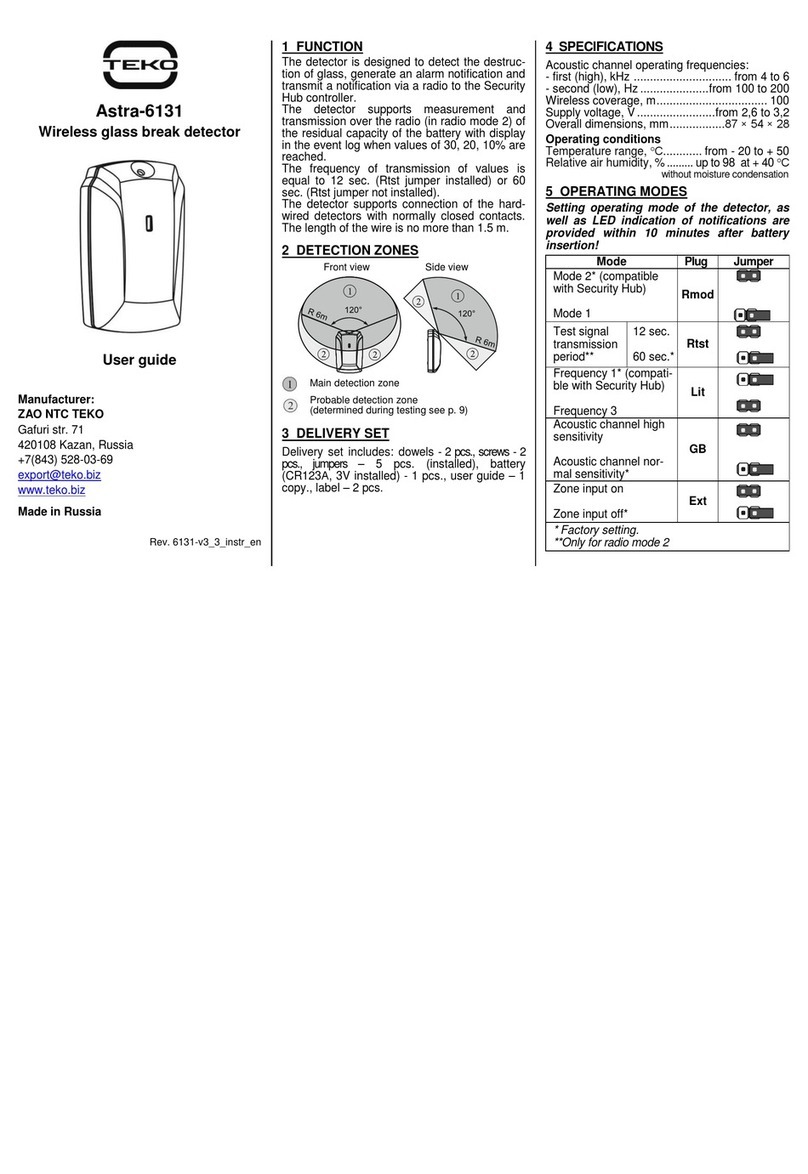

AC Channel

Maximal detection range in a sector

of volumetric angle of 120° from center of

microphone, m, not less than..................................................6

General Technical Parameters

Power supply voltage, V...................................from 8 up to 15

Current consumption in all modes, mA, not exceeding.........15

Permissible relay contacts current, A, not exceeding ..........0,1

Permissible voltage on relay contacts, V, not exceeding....100

Resistance of circuit, connected to

signaling zone, Ohm, not exceeding...................................... 8

Technical readiness time, s, not exceeding..........................60

Overall dimension, mm, not exceeding...............110 × 60 × 45

Detector weight, kg, not exceeding....................................0,09

Operating Conditions:

Temperature range, °C ................................from -20 up to +50

Relative air humidity, %............................. up to 95 at + 35 ºС

Without moisture condensation

4 Delivery Set

Dual channel detector Astra-621 .................................... 1 pcs

Screw 2.9×25 (or 2-3х30) ................................................ 2 pcs

Dowel 5х25...................................................................... 2 pcs

Sealing material............................................................... 1 pcs

User Instruction.............................................................. 1 copy