Astra-9 (Volumetric Lens)

Optic-Electronic PIR Motion Detector

Operating Manual

Rev. 9-v3_7_en

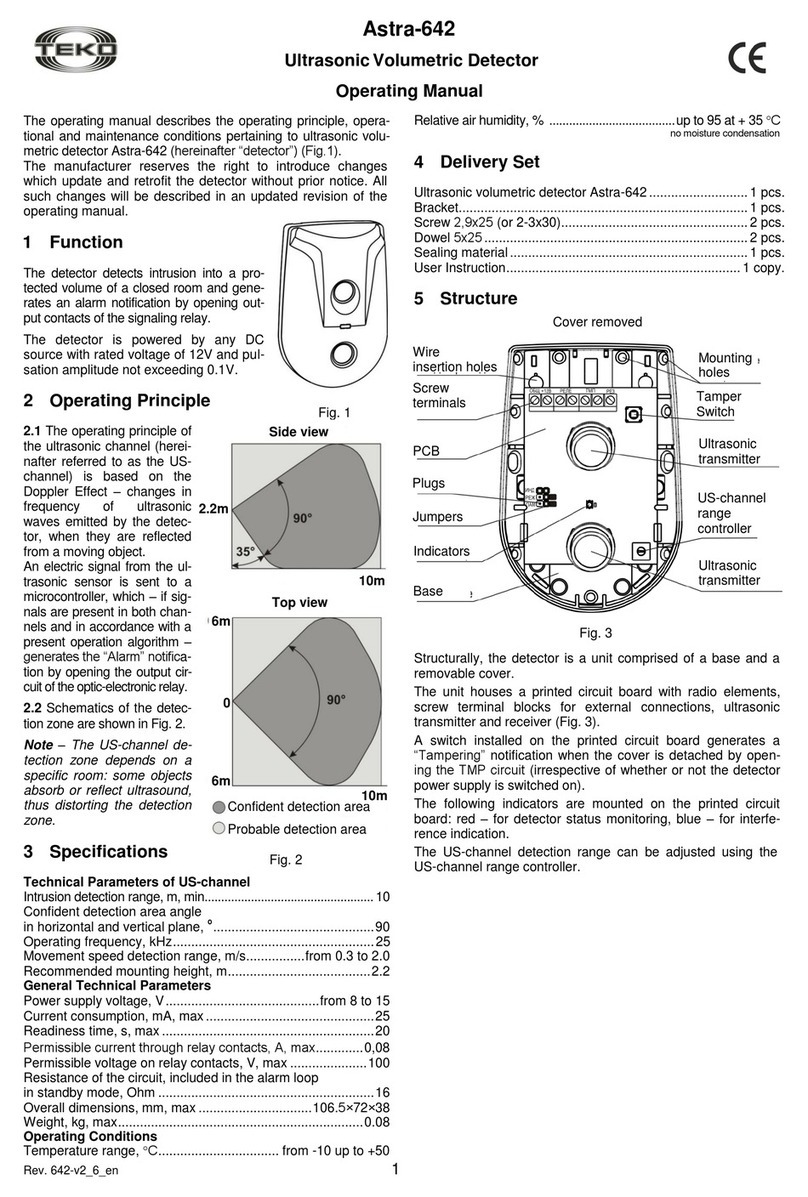

The present operation manual is intended for studying operation

principle, running conditions and maintenance of PIR motion de-

tector Astra-9 (hereinafter referred to as “the detector”) (Fig.1).

1 Function

Detector is intended to detect

unauthorized access into closed

protected area, and to generate an alarm

notification by opening of alarm relay

contacts.

Power supply of detector is performed

from any direct current source with

nominal voltage 12V and pulsation

amplitude not exceeding 0,1V.

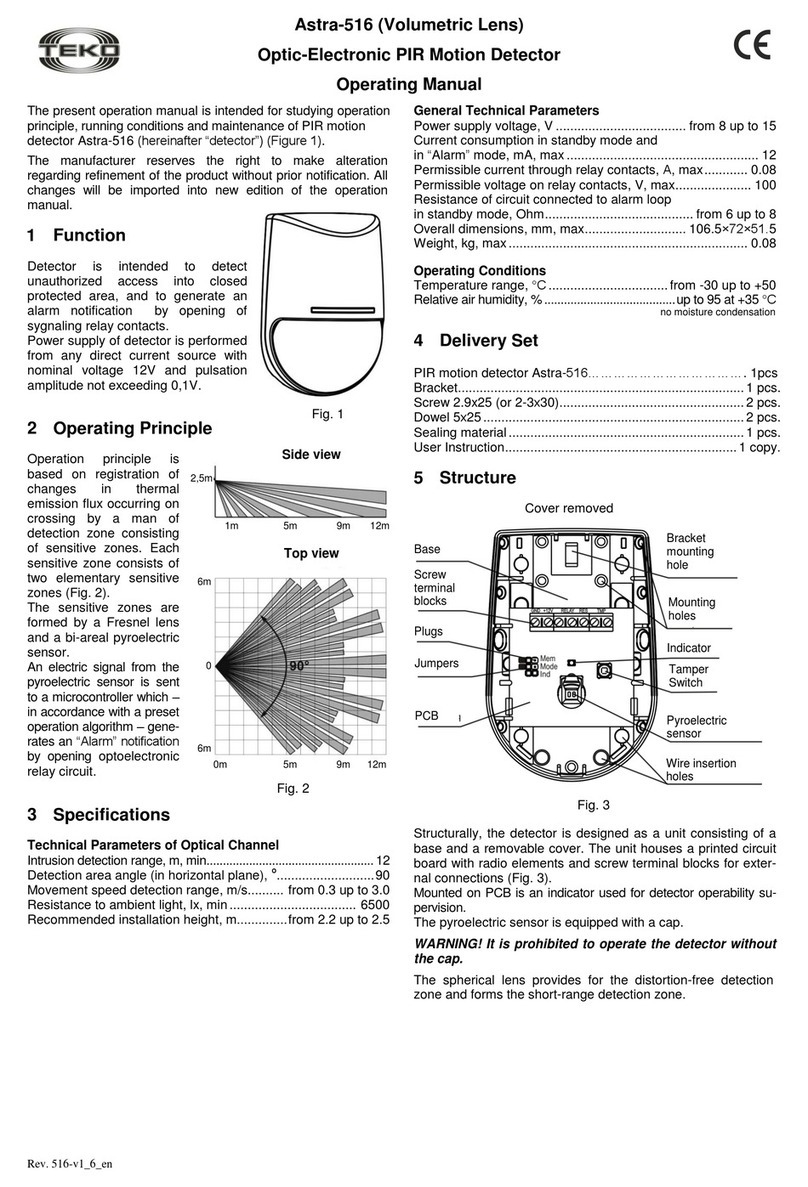

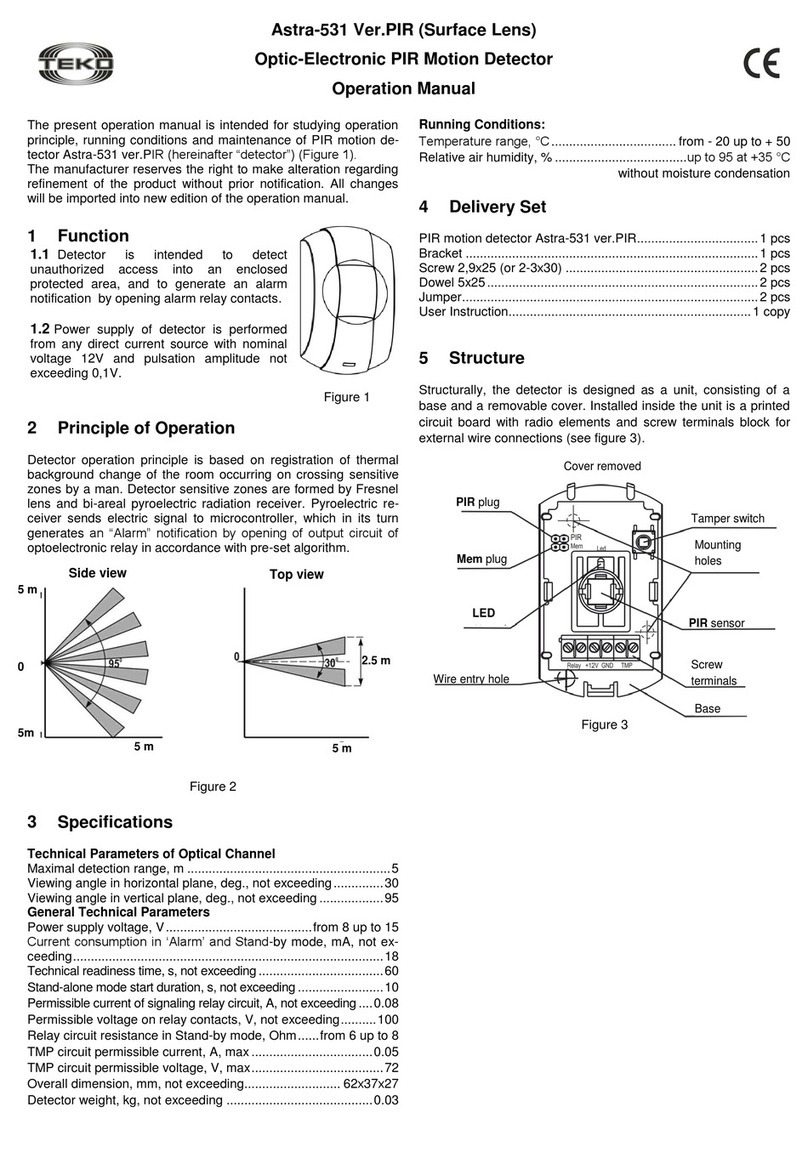

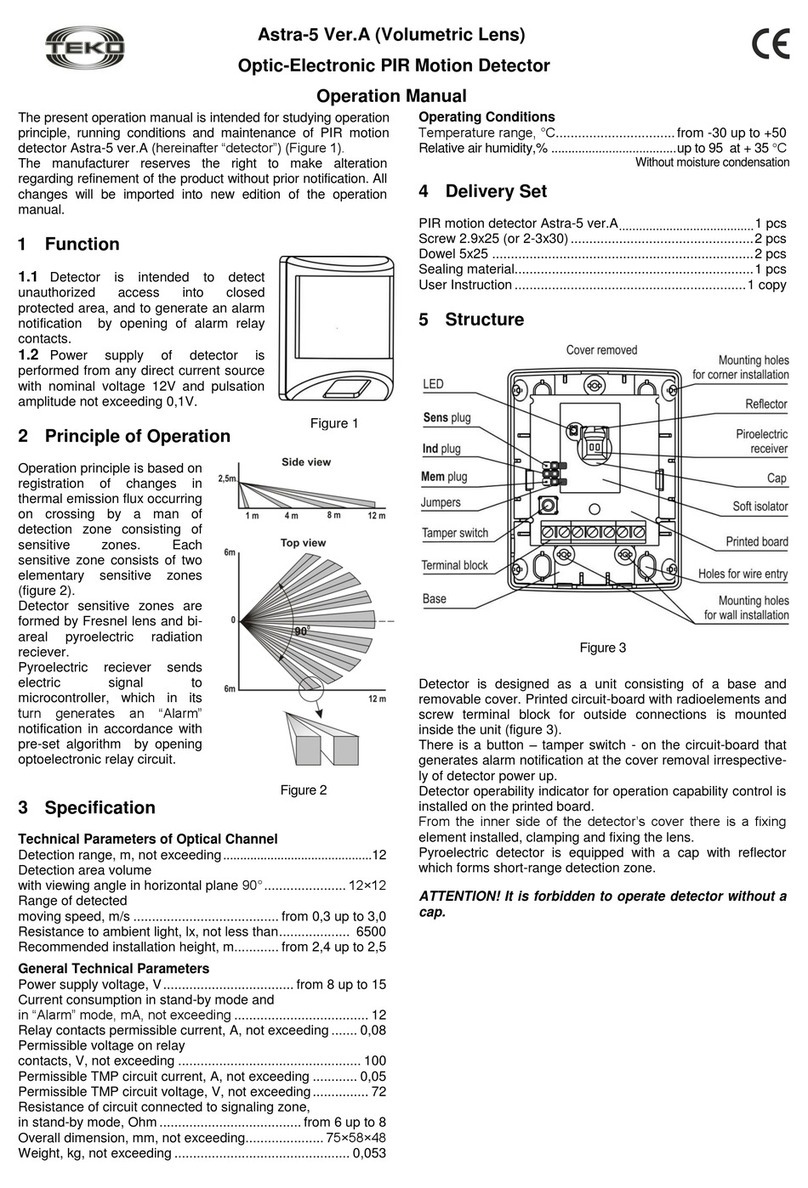

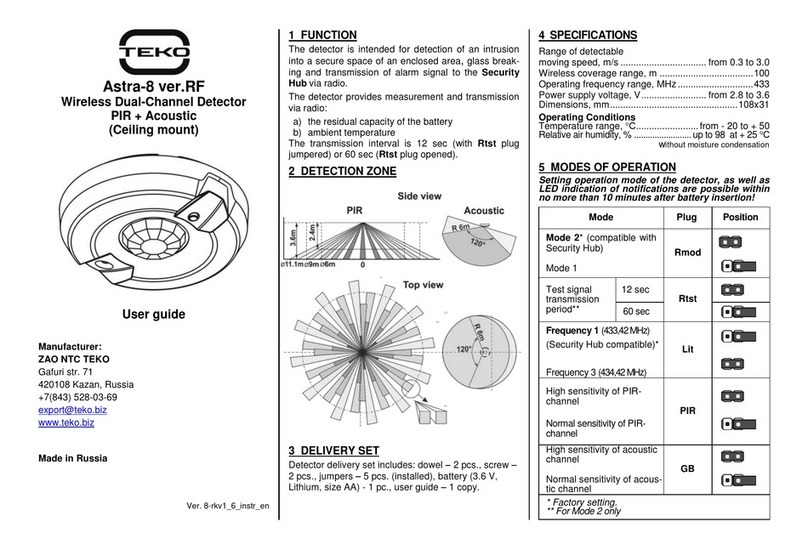

2 Operating Principle

Operation principle is based

on registration of changes in

thermal emission flux

occurring on crossing by a

man of detection zone

consisting of sensitive zones.

Each sensitive zone consists

of two elementary sensitive

zones (figure 2).

The sensitive zones are

formed by a Fresnel lens and

a bi-areal pyroelectric sensor.

An electric signal from the

pyroelectric sensor is sent to

a microcontroller which –in

accordance with a preset

operation algorithm –gene-

rates an “Alarm” notification

by opening optoelectronic

relay circuit.

The detection zone size can

be changed by changing po-

sition of the detector printed

circuit board. If the intrusion

detection range is reduced to 7 m, density of the sensitive

areas will increase.

3 Specifications

Optical Channel Parameters

Intrusion detection range, m, min:

- in the lower PCB position ............................................................10

- in the upper PCB position.............................................................. 7

Detection zone size at the detection angle

of 90оin horizontal plane, m:

- in the lower PCB position..................................................10×10

- in the upper PCB position...........................................................7×7

Movement speed detection range, m/s...........from 0.3 up to 3.0

Resistance to ambient light, lx, min................................... 6500

Recommended installation height, m............. from 2.4 up to 2.5

General Technical Parameters

Power supply voltage, V .................................... from 8 up to 15

Current consumption in standby mode and

in “Alarm” mode, mA, max ..................................................... 15

Relay contacts permissible current, mА, max..................... 0.08

Relay contacts permissible voltage, V, max......................... 100

Resistance of circuit, connected to signaling zone

in standby mode, Ohm, max ................................................... 8

Overall dimensions, mm, max.................................... 76×58×46

Weight, kg, max................................................................ 0.085

Operating Conditions

Temperature range, °С.................................from -30 up to +50

Relative air humidity, %.......................................up to 95 at + 35 °С

no moisture condensation

4 Delivery Set

PIR motion detector Astra-9...............................................1 pcs.

Screw 2.9x25 (2-3х30).......................................................2 pcs.

Dowel 5х25........................................................................2 pcs.

Sealing material.................................................................1 pcs.

Bracket-01 ........................................................................1 pcs.

User Instruction................................................................1 copy.

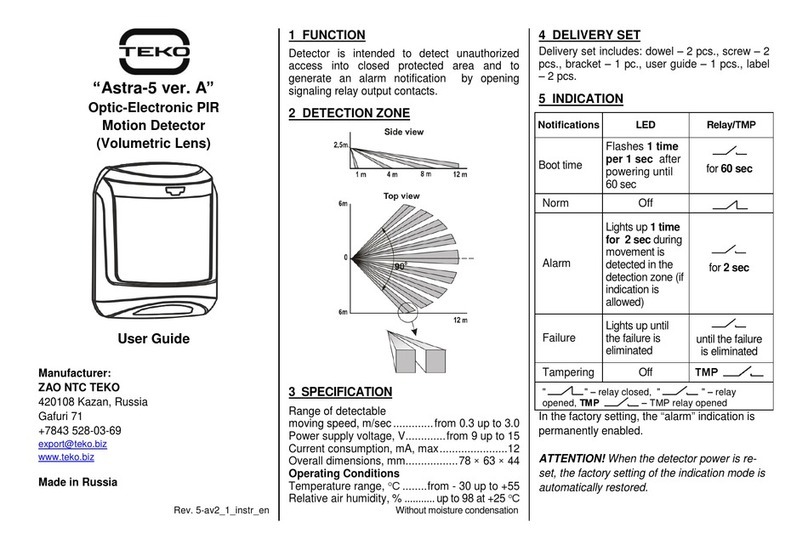

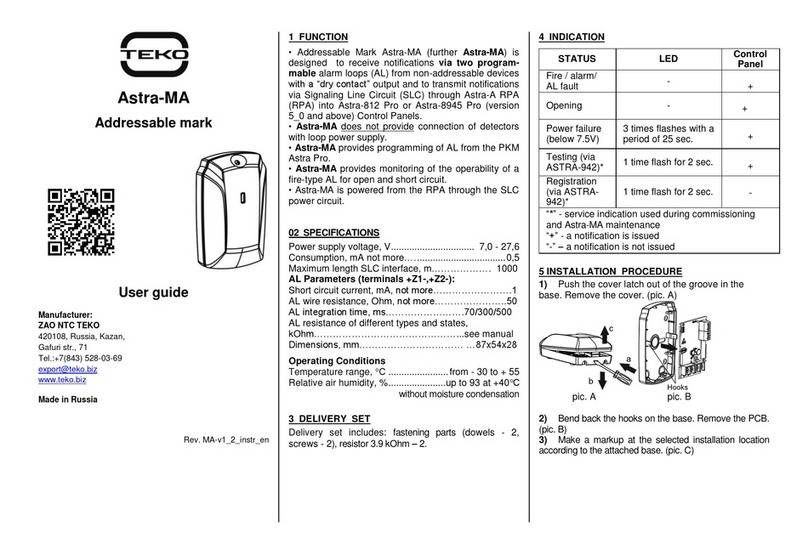

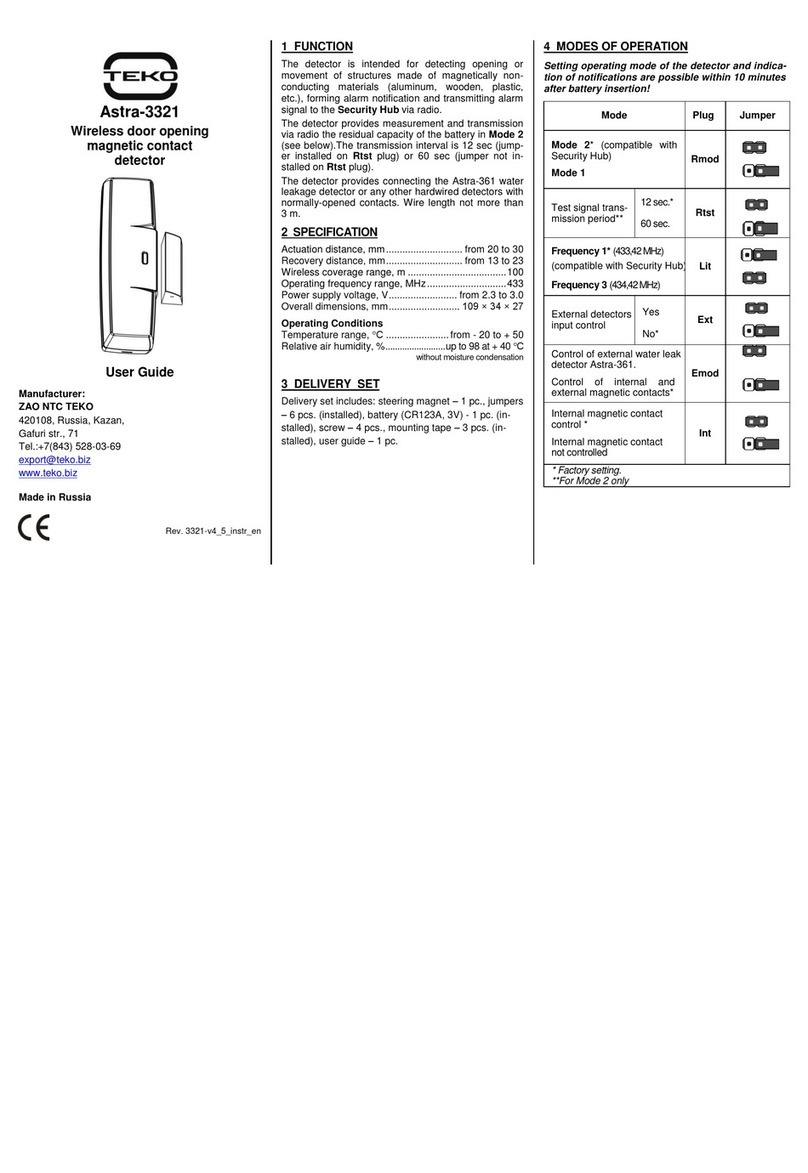

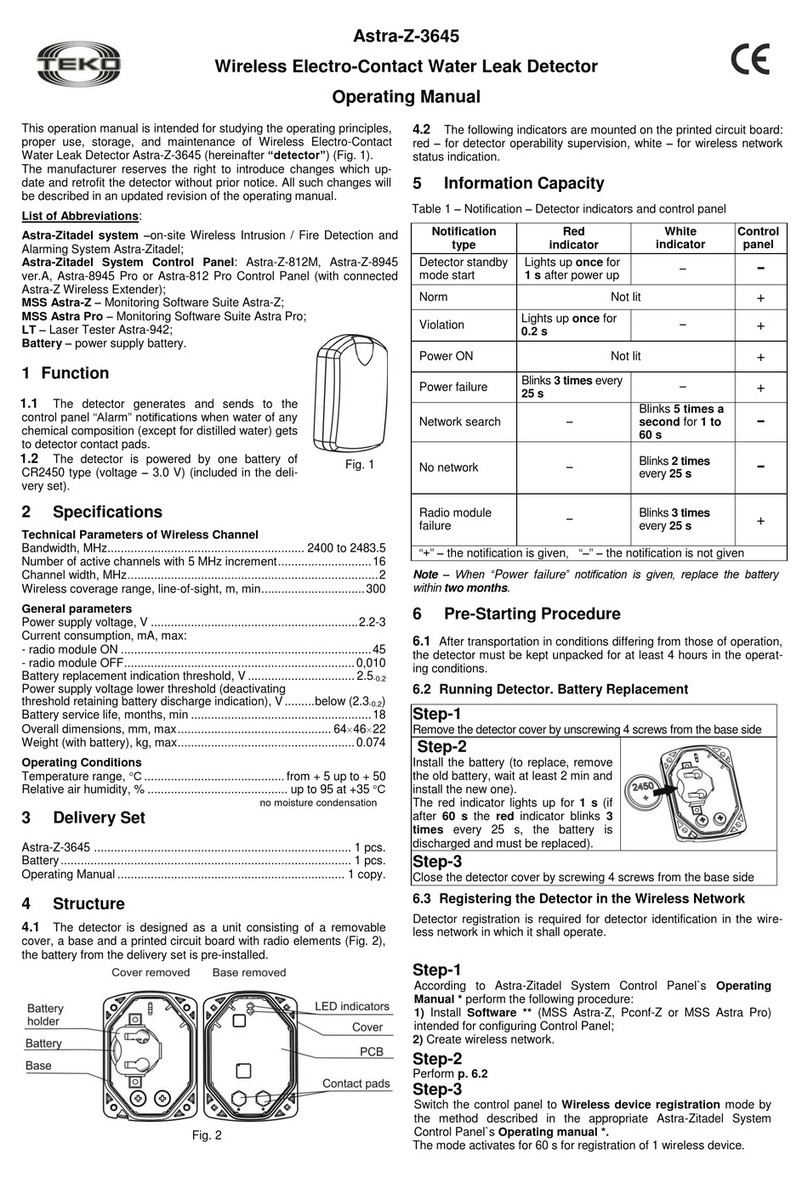

5 Structure

Fig. 3

Structurally, the detector is designed as a unit consisting of a

base and a removable cover. Printed circuit-board with

radioelements and screw terminal block for external

connections are mounted inside the unit (Fig. 3).

Mounted on the detector base is an eccentric; by rotating the

eccentric one can change the position of the printed circuit

board.

Mounted on the circuit board is an indicator for detector operabil-

ity supervision.

Mounted inside the detector cover is a fixing piece pressing

down the lens and fixing its position.

The pyroelectric sensor is equipped with a reflector cap which

forms short-range detection zone.

WARNING! It is prohibited to operate the detector without

the cap.