Start-up

protection

Over heat

protection

ESC will cut off output if it fails to start the motor within 3 seconds by accelerating throttle. you need to move the throttle

back to the neutral position and restart the motor.( The possible causes : Bad connection or disconnection between

ESC & motor , propellers are blocked, etc)

When ES C temperature is higher than 100 ℃,it will reduce output power (throttle will be limited below 40%) for protection,

make the motor has enough power for return , when the temperature drops to 80℃ , ESC will return to normal working.

ES C detects the loss of throttle signal for over 1 seconds during motor running, it will cut off output immediately to avoid

an even greater loss caused by the continuous high speed rotation of motor. E S C will return the corresponding output

after the signal is restored.

Throttle signal

loss protection

ATTENTION

User Manual

Brushless ESC For RC Boat

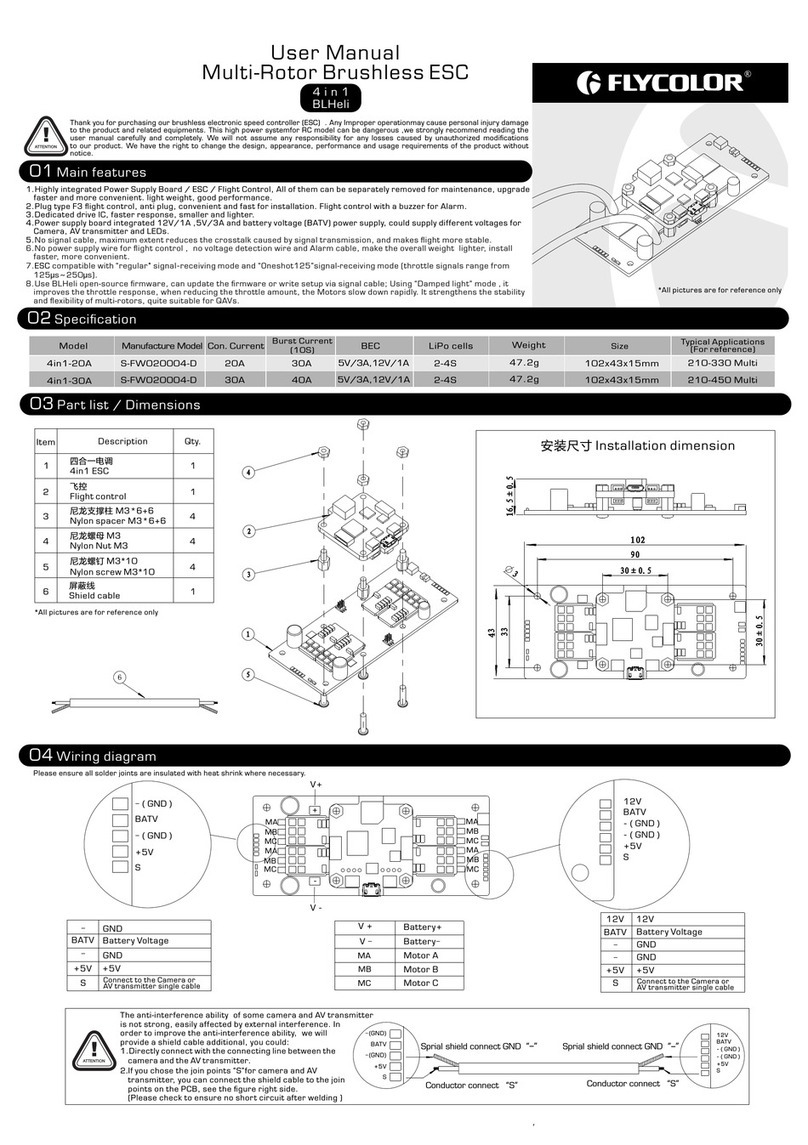

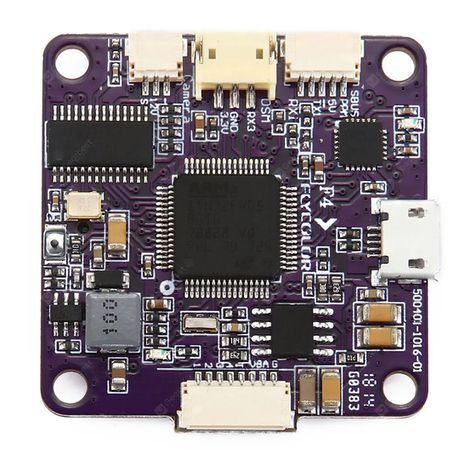

01Main features

After motor emits a

Item tone ,move the

trigger or stick to the

neutral position,

then will enters this

item, and motor will

emits the parameter

tone in a loop .

Please see the table

below)

Item parameter

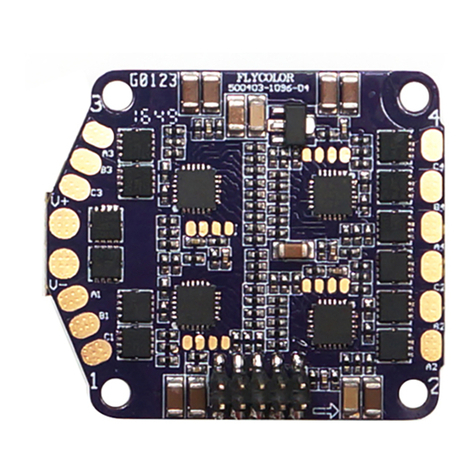

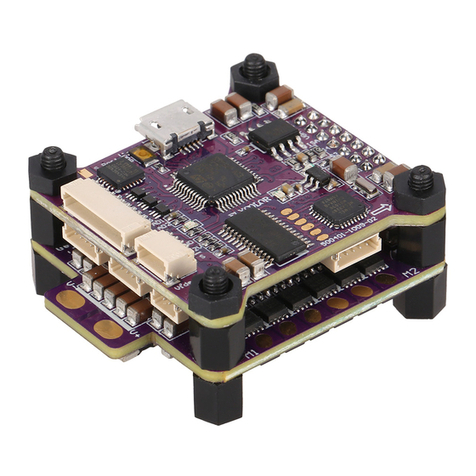

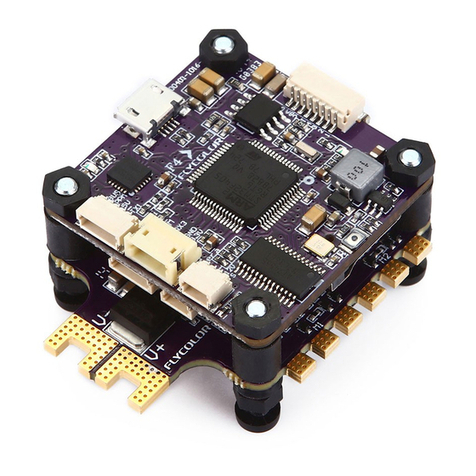

03 Wiring Diagram

Shadow parts are factory default value.

*In some specific cases, the E SC can work under 2S . For 2S, when the battery voltage is lower than 6V,

the ESC will not work or the B EC output will be below the nominal value.

www.flycolor.net

06 T rouble Shooting

Thank you for using our product. Any improper operation may cause personal injury or damage the

product and relevant equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

02 Specifications

After power on, the motor doesn't work and

doesn't emit any sound.

Bad connection between ESC and battery.

Bad soldering cause bad contact.

Low voltage of the battery.

Water got in, damage or other quality

problems with E SC.

Clean the connectors or replace them, check and

confirm that the polarity is correct..

Solder the wires again.

Check battery voltage, use full-charged battery.

After power on, E SC emits the sound of

battery cells, but motor doesn't work. ES C doesn't calibrate throttle range.Calibrate throttle range again.

After power on,E SC works ,but the motor

doesn't work and doesn't emit any sound.

Bad connection between ESC and motor, or

bad soldering.

Bad motor.

Battery voltage out of range

Check the connectors or replace the connectors or

solder the motor wire again.

Change motor.

Check the battery voltage is within the range of ESC.

After powering up, motor doesn't work and

emits warning tone“B-,B-,B-”(emits every 2

seconds).

No throttle signal from receiver.

1.Check if right connection between signal wire and

receiver throttle channel.

2.Check remote control and receiver, make sure there

are signal outputs.

After power on, the motor doesn't work and

emits continuous warning tone“B-B-B-B-B-”

(urgent short tone).

Throttle trigger or stick doesn't in the

neutral position (zero position).

Move the throttle trigger or stick to the neutral

position, or Calibrate throttle range again.

After power on, the motor doesn't work.

Motor emits 2 long “B-” and 2 short “B-”.

The positive and negative of throttle channel

is wrong. So ESC enters programming mode. Refer to the user instruction of transmitter, adjust

the setting of throttle channel.

Motor rotates in the opposite direction. The wrong sequence of connection wires

between motor and E SC.

1.Exchange random 2 of the 3 connection wires

between ES C and motor.

2.Change motor rotation direction via mobile phone

App or Remote control.

Motor stops during running Loss throttle signal

Bad connection between wires

Troubles Possible causes Solutions

Battery voltage is lower than low-voltage

protection threshold.

1.Check if the operate correctly. remote control

2.Check if match with the receiver.remote control

3.Check if the signal wire is loose or falling off.

4.Strong electromagnetic interference around the

environment, try to turn off and power up again, to

see if it recovers normal work, if the problem come

up again and again, please change to another field.

251400-1138 V1.0

Alarm tone: (To judge the abnormal cases via alarm tone )

1. Alarm of throttle signal is not detected:

ESC detects no signal when power on, motor will emit the alarm tone “B-、B-、B-”(emits every 2 seconds).

2. Alarm of throttle not in the neutral position:

Throttle not in the neutral position, motor will emit “B-B-B-B-” ( urgent short tone).

3. Alarm of voltage out of range:

The ESC detects that the battery voltage is higher than rated voltage when power on, , motor will emit“B-B-, B-B-, B-B-”(emits every 1.5 seconds).

4. Alarm of narrower throttle range:

when throttle range is set too narrow, motor emits “B-B-B-”( urgent short tone, stop after 2 seconds). You must set throttle range again.

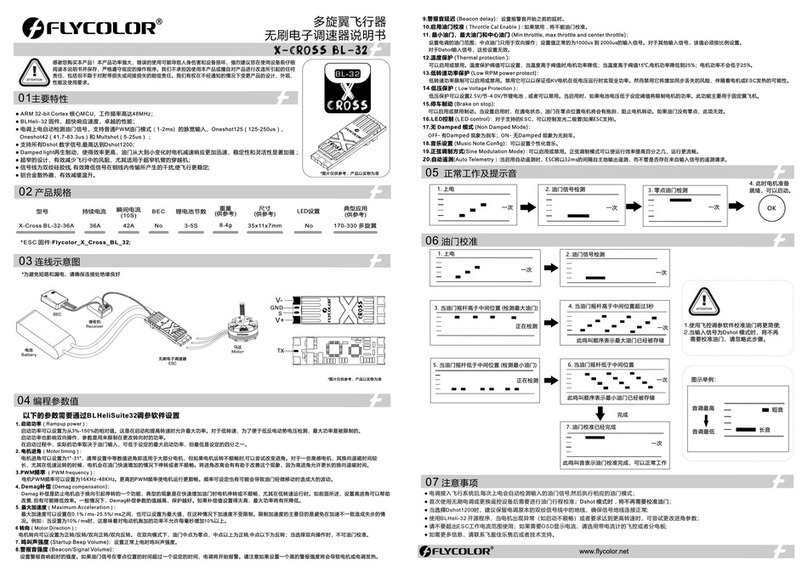

Iterm

1.Running Mode

2.Motor Running

Direction

Check the connectors of battery pack, battery wires

and motor wires connections are good.

3.Low Voltage

Threshold

4.Start Acceleration

5.Motor Timing

6.BEC Voltage

Burst Current

(Good heat dissipation)B EC Size

(For reference)

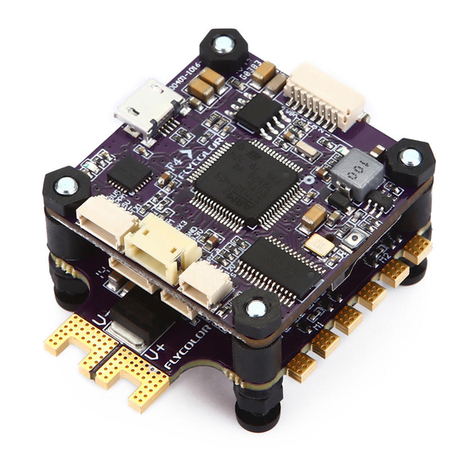

Model

LiPo

Weight

(For reference)

Con. Current

(Good heat dissipation)

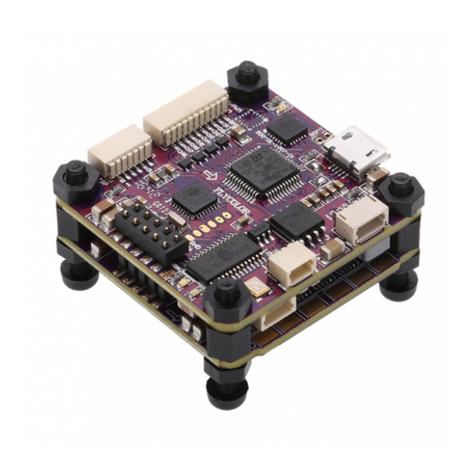

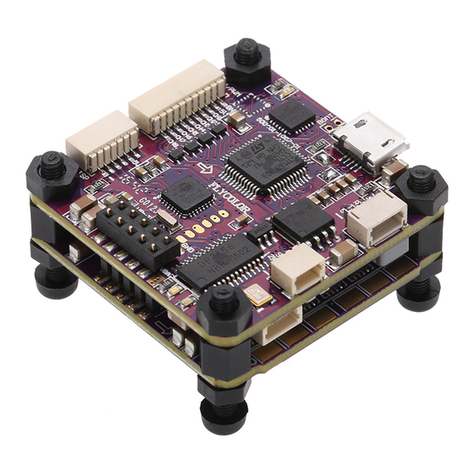

Kraken Series(Wifi)

7.LiPo Cells

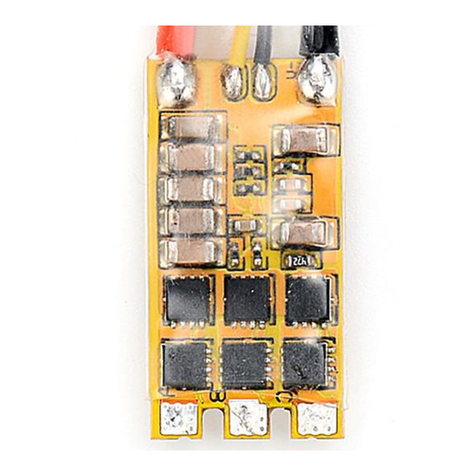

● STM32F051 MC U with 32-bit cortex core and working frequency of 48mhz;

● Small in size and light in weight, especially suitable for race class boat;

● Support brushless motor up to 240k erpm;

● The starting mode can be set, throttle response fast, and the speed regulation linearity is very stable. which

is suitable for various RC boat.

● Multiple protection make the equipments safety. Beeping alarm can indicate working condition.

● Low voltage protection threshold can be set to meet personalized needs;

● Good safety performance when power on, when power on, the motor will not be started immediately regardless

of the throttle position of the remote controller.

● Cycle programming menu for easy operation. Compatible with all kinds of remote controls.

● Built in 6V/7.4V,5A adjustable switch BEC .

● Nanometer waterproof coating, anti splash water .

● Water cooled aluminum heat sink can effectively slow down the temperature rise.

● Support programming via mobile phone APP (extra Flycolor Wi-Fi Trans needed).

● Support close-range detection and recording of real-time data via mobile phone APP, such as current, voltage, R PM, temperature ...(extra Flycolor

Wi-Fi Trans needed).

● Support speed up function, suitable for sudden increase of motor rotation speed in the final sprint to get faster running speed.

6V/7.4V,5A

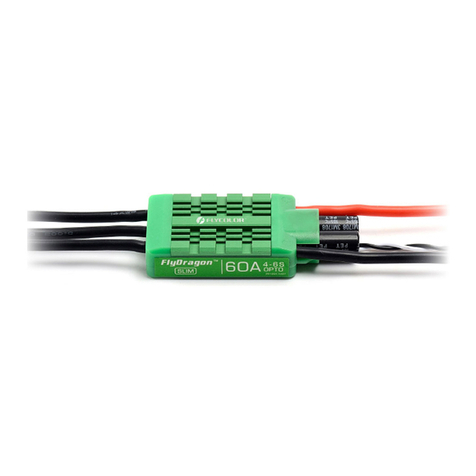

40A 60A 3-6S

60A

80A

3-6S

90A 110A 3-6S

Kraken 90A (Wifi)

Kraken 60A (Wifi)

Kraken 40A (Wifi)

6V/7.4V,5A

6V/7.4V,5A

120A 140A 3-6S

Kraken 120A (Wifi)

6V/7.4V,5A

150A 170A 3-6S

Kraken 150A (Wifi)

6V/7.4V,5A

180A 200A 3-6S

Kraken 180A (Wifi)

6V/7.4V,5A

ESC

Wi-Fi Trans wire

2

1

Motor

Throttle signal

&BEC wire

Receiver

Battery

*Please ensure all solder joints are insulated well where necessary.

04 Protections

05 Operation instruction

Power on safety

protection

If the throttle is not in the neutral position after power on, the motor will emit alarm. The motor can not be started until

the neutral position throttle is detected.

Low voltage

protection

If the voltage is lower than the set low-voltage protection threshold, E S C will automatically reduce the output power

for protection. After running for several seconds, the motor will stops, it can restart when the throttle returned to

neutral position. The above operation can be repeated.

Note: the following are the diagrams of pistol or stick remote control with neutral position (zero point), which are recommended for Unidirectional

and Bidirectional running modes; in addition, stick remote control without neutral position can be selected for unidirectional operation.

SU

Speed Up function wire

3

S + G

P + G SU

Speed Up Function

Programming-To“S”on Wifi Trans

Vout-Power to Wifi Trans

GN D

Throttle signal-To“S” on receiver

BE C Vout

GN D

1

2

: Plug it into & Throttle signal wire the throttle channel on the receiver, the white wire is for transmitting throttle signal, the red black wires are the

BEC output wire and ground wire.

Wi-Fi Trans wire Connect with Flycolor Wi-Fi Trans : , supports programming and detection of real-time data at close range via mobile phone APP.

Speed Up : Plug it into an two-stage switch channel on the receiverFunction wire , during the running, the speed is increased by triggering the switch.

3

SU

●40A

●60A

SU

●90A

●120A

SU

S

+

G

P + G

180 3 - 6 S

6V/7.4V, 5A

A

●150A

●180A

SU

Clean up and dry the water of ESC ,try again ;

Replace ES C .

*There are differences in the appearance of the products, the pictures are the representative models for reference only.

ATTENTION

●It is suggested that users should do extra waterproof to get better waterproof effect. If there is water on E SC after use, please dry the

water before use ,in order to avoid damaging the product).

●There is different with remote controls , some receivers generate signals when the remote control is not turned on. To avoid injury,

please turn on the remote control first and then power on the ESC at any time.

●, to get the most stable throttle linearity for different remote controls ,andIt is recommended to calibrate throttle range for the first time

let the ESC acquire and memorize the throttle output signal of the remote control. This operation only needs to be carried out once,

and needs to be repeated when replacing the remote control.

● Before normal start-up, according to the actual number of battery cells used, it is recommended that the user should select the fixed number of

battery cells via programming. In combination with the low voltage protection, it can effectively prevent the battery from over discharge.

1

Throttle Range calibration

。

2

Normal start-up

Turn on the remote control, move

trigger or stick to the full throttle

position, then power on.

Turn on the remote control, leave the

throttle trigger or stick at the neutral position.

Wait for 2 seconds, after motor emits

2 short "B-B-",the full throttle position

is memorized. Leave the throttle trigger

or stick to the neutral position in 5 seconds.

Then waits for 1 second, Motor

emits short "B-" several times,

sound times is the number of

battery cells.

Then the motor emits a long

and a short tone means the“zero

throttle“position is memorized.

ES C is ready for

working now.

C o n n e c t E S C w i t h b a t t e r y.

Wait for 2 seconds, motor emits

sho rt“ B-” seve ra l times, so un d

times is the number of battery cells.

Then waits for 1 second,the motor emits

1 long and 1 short tone.

ESC is ready for working now.

Option 1 Via Wi-Fi Trans: (recommended)

WiFi

Wi - F i Tr a ns w i r e

(E S C)

Wi - F i Tr a ns w i r e

3

Programming

●Flycolor Wi-Fi TransPlease refer to the user manual of ;

●Wi-Fi Trans needs to be purchased separately.

●Download and install the flycolor configurator App.

Note:

Usually,1 long tone

"Beeeep--" equals to

5 short tone"beep-",

for example:1 long

tone"Beeep--" and 1

short tone “beep-”

equals to 6.

When motor emits

“Exit” tone,

move throttle to

neutral position

(zero point) in 3

seconds, then motor

emits special tone

“♪765765”, it will

exit the programming

mode.

If don't want select

other parameter,

move the trigger or

stick to the neutral

position in 3

seconds, then motor

emits special tone

“♪765765”, it will

exit the programming

mode. Or power off,

it will exit the

programming mode.

♪12321

Running Mode 1short

Motor running direction 2short

3short

Start Acceleration

Motor Timing

BEC Voltage

4short

Restore factory defaule

Exit

1long

1long&1short

1long&2short

1long&3short

Beep-

Beep-Beep-

Beep-Beep-Beep-

Beep-Beep-Beep-Beep-

Beeeep--

Beeeep--Beep-

Beeeep--Beep-Beep-

Beeeep--Beep-Beep-Beep-

123 4 56 7 8

1short 2short 3short 4short 1long 1long&

1short

1long&

2short

1long&

3short

Unidirectional Bidirectional

Normal Reverse

No 2.6V 2.8V

0°3.75°7.5°11.25°15°18.75°22.5°26.25°

6V 7.4V

Prompt

tone

Low Voltage Threshold

Move the trigger or stick to the full

throttle position after a certain

tone that the parameter you

want, the parameter is

selected, then motor emits

special tone“♪1212”, this

parameter will be stored.

Just wait If you still want select

other item, it will go back to the

Level 1 menu to select item, the

operate method is the same.

3.0V 3.2V 3.4V

Level 1 Level 2 Level 3 Level 4 Level 5

1long&4short Beeeep--Beep-Beep-Beep-Beep-

LiPo Cells

Auto 2S* 3S 4S 5S 6S

Wait for 2 seconds,motor emits 2 short "B-B-".

Then still wait for 5 seconds. motor emits

special tone“♪12321”,it has entered

programming mode.

Select Items

After entering programming mode, you will hear groups tone which

emits in a loop as following sequence .

1

2

3

4

5

6

7

8

9

Option 2 Via : Remote Control

ES C parameters can be programmed by remote control.

Turn on the remote

control, move

trigger or stick to

the full throttle

position, then

power on.

1. Running Mode:

[1]Unidirectional(default): It can only move forward, no effect when move the trigger or stick from forward to reverse.

[2]Bidirectional: When move the trigger or stick from forward to reverse, the motor will immediately reverse after it stops running. (The maximum

throttle of forward and reverse is equal)

2.Motor Running Direction:

[1]Normal(default):Default motor rotation direction;

[2]Reversed:Change the direction of rotation of the motor.

3. Low Voltage Threshold:

[1]No [2]2.6V [3]2.8V [4]3.0V(default) [5]3.2V [6]3.4V

In order to keep the battery at a safe minimum voltage (for LiPo batteries). The ES C monitors the battery voltage all the time, when the voltage goes

below the threshold,ESC will be protected immediately. Please set to “Disabled” if you’re using NiMH batteries.

4. Start Acceleration:

[1]Level 1 [2]Level 2 [3]Level 3(default) [4]Level 4 [5]Level 5

It can be adjustable from 1 to 5,set a high value to have a quick start-up response, but requires high discharge capacity of the battery.

5. Motor Timing:

[1]0° [2]3.75° [3]7.5° [4]11.25° [5]15°(default) [6]18.75° [7]22.5° [8]26.25°

As usual, 15° applies to all the outer rotor motors , but for improving efficiency ,recommend that set low timing for 2 poles motor( most inner rotor

motors), set high timing for 6 poles and high poles motors( most outer rotor motors). If need high speed motor, you can set high timing. Some motors

should set special timing, if not sure, you'd better to set timing as motor manufacturer recommended ,or set 15°.

Note: After changing timing, please test on the ground before running.

6.BEC Voltage:

[1]6.0V(default) [2]7.4V

BE C can be selected according to the actual demand.

7.IiPo Cells: (Available for LiPo battery only)

[1] Auto(default) [2]2S [3]3S [4]4S [5]5S [6]6S .

Auto:The number of battery cells will be automatically determined according to the current voltage every time the E SC is restarted or powered on;

if "Auto" is selected, please always pay attention to the battery voltage to avoid battery over discharge.

2-6s (recommended): Users are advised to select a fixed value according to the actual number of batteries used. With the low voltage protection ,

the battery can be effectively prevented from over discharge.

8.Restore factory default:

When the beeping indicates the "Restore default settings", move the throttle trigger or stick to neutral position in 3 seconds. There is no sub-menu

under this mode,then motor emits special tone “♪765765” which means default settings are restored.

9.Exit:

When the beeping indicates the "Exit" mode, move the trigger or stick to the neutral position in 3 seconds, then motor emits special tone “♪765765”,

it will exit the programming mode.

Parameter description

4

Speed Up Function

Speed Up Function is suitable for sudden increase of motor rotation speed in the final sprint to get faster running speed.

Plug the speed up into an two-stage switch channel on the receiverfunction wire , during the running, the speed is increased by triggering the switch.

Speed up function effective conditions:

1) It is required that the maximum value of channel shall be greater than 1500us.

2) The setting value of motor timing should be less than 26.25 ° in order to be effective; if the motor timing is set to 26.25 ° then the speed up function

is invalid.

After power on , the motor doesn't run and

emits warning tone“B-B- ,B-B-,B-B-”.(emits

every 1.5 seconds)

1. Drive back in time, check the battery voltage

and charge the battery;

2. Pay attention to the voltage of the remote

control within the controllable range .it needs to

drive back in time if the voltage is low .

42g

46g

82.5g 95.5x37.5x13mm

70x35x9.5mm

66x35x9.5mm

90g 98x37.5x13mm

135g 110x49x15mm

135g 110x49x15mm