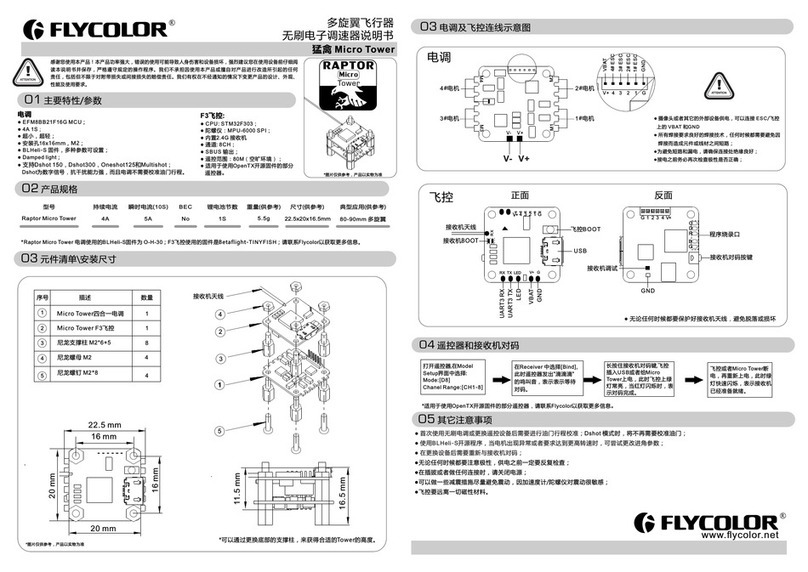

BEC

ATTENTION

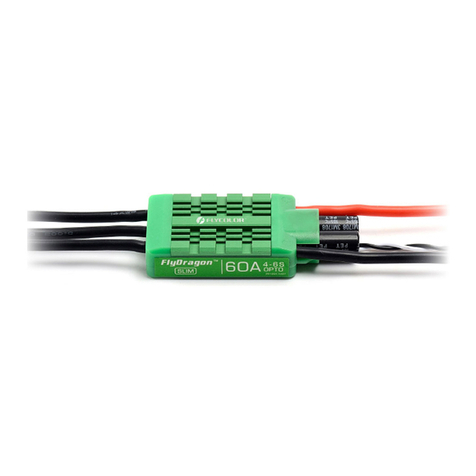

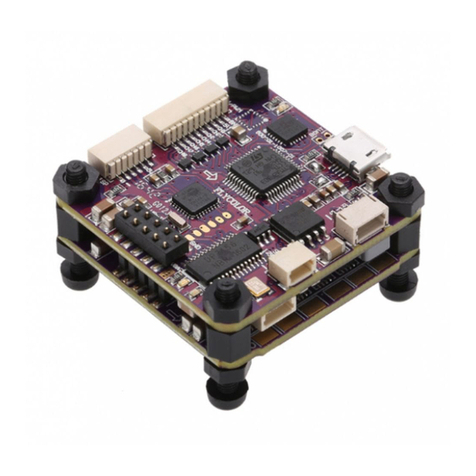

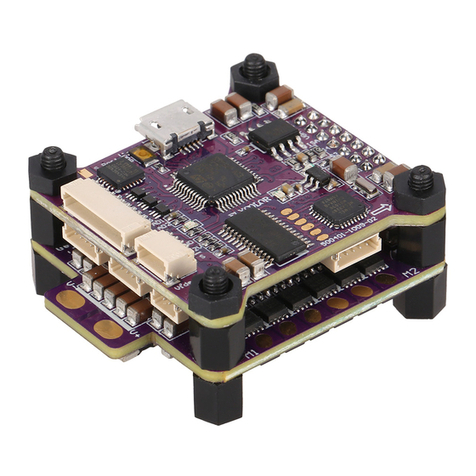

RAPTOR

SLIM

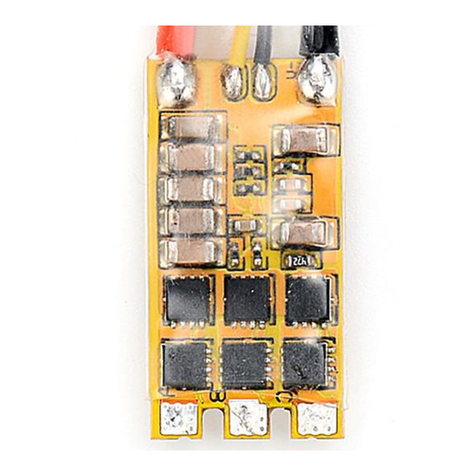

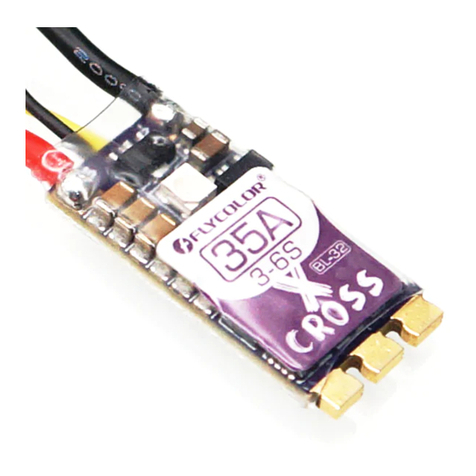

Raptor S LI M -40A 40A 50A 2-4S 9.1g 170-330 Multi

No 35x10x7mm

RA P T OR

SL I M

40A 2- 4S

Battery

Receiver

BEC

ESC

Motor

RA P TOR

SLI M

40 A 2- 4S

RAPTOR SLIM

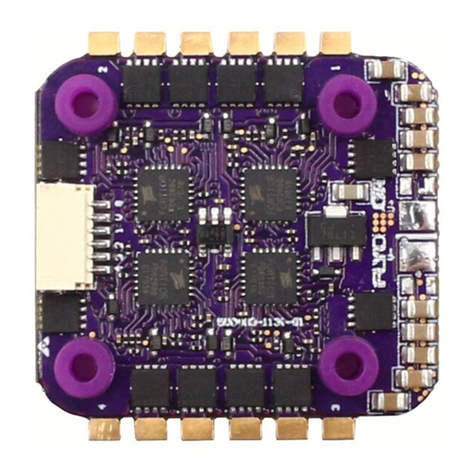

02 Specifications

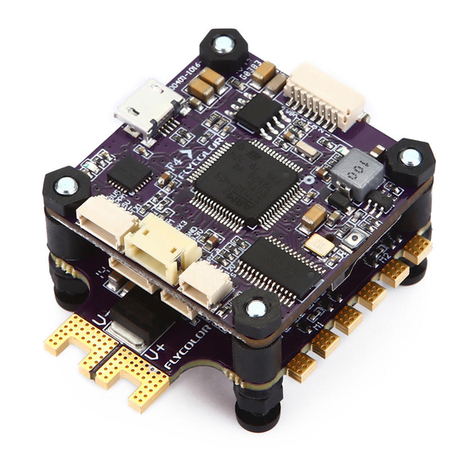

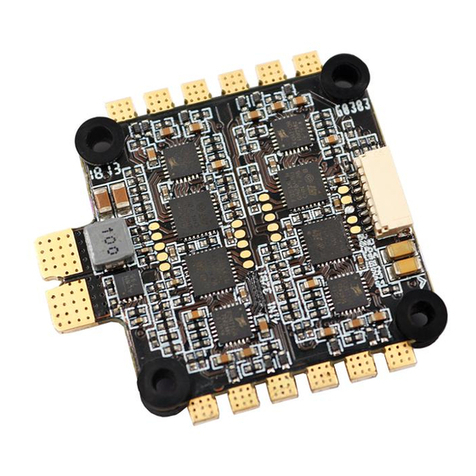

01 Main features

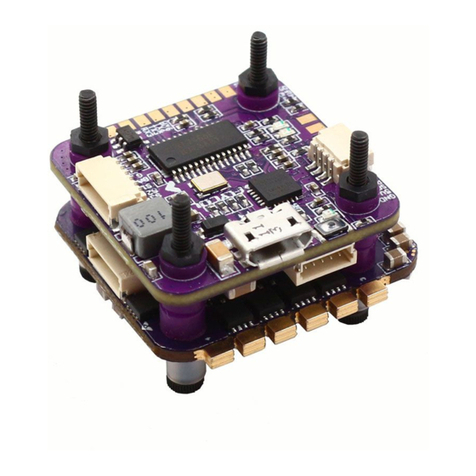

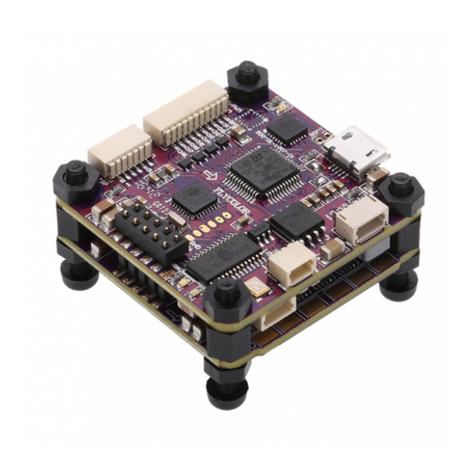

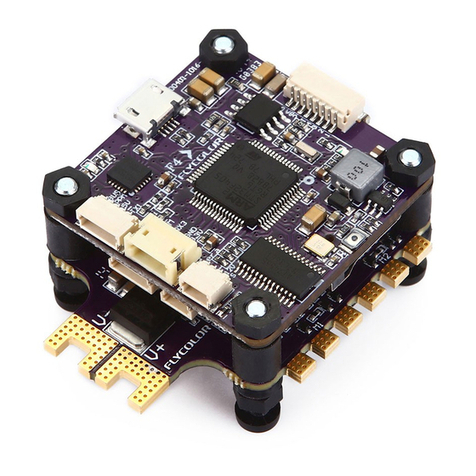

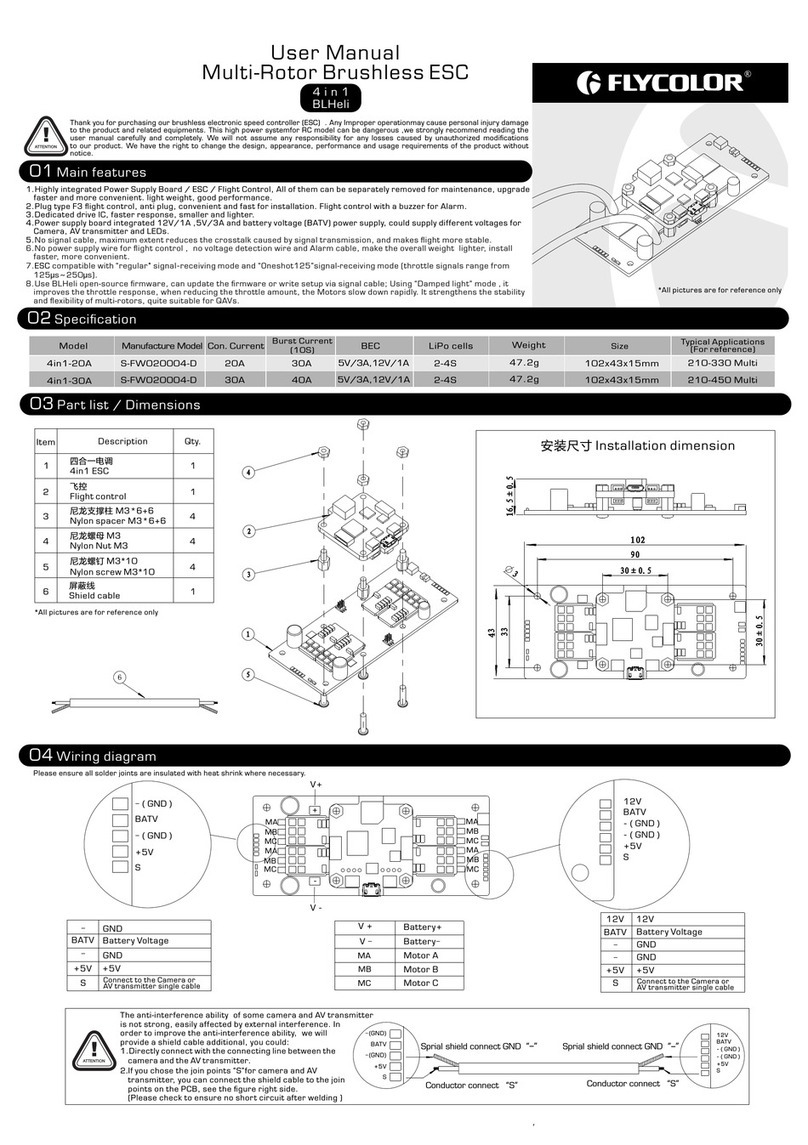

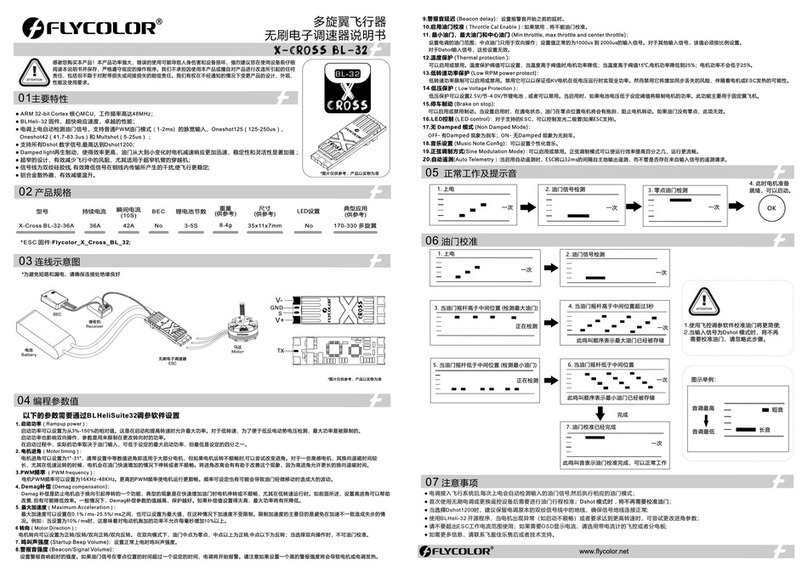

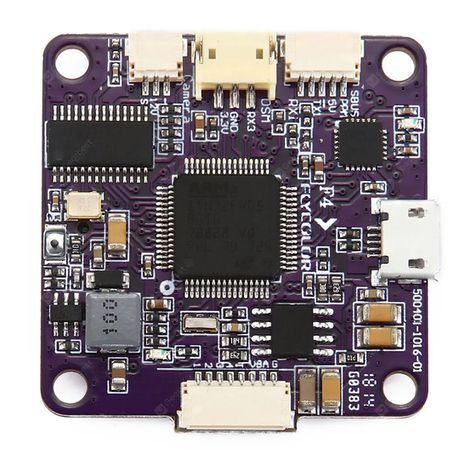

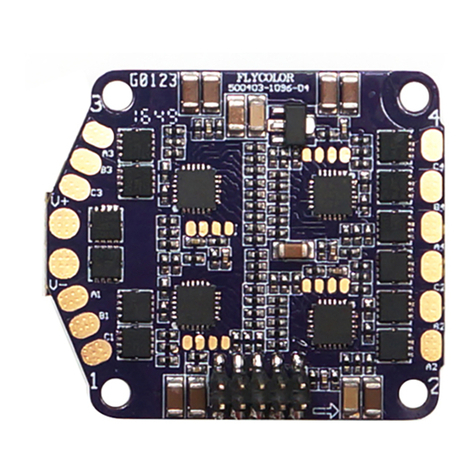

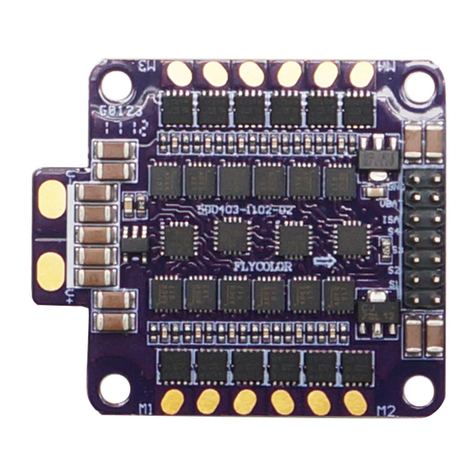

03 Wiring diagram

04 Programming parameter

05 Beeps-Normal operation

06 Beeps - Throttle calibration

07 Attention

User Manual

Multi-Rotor Brushless ESC

Thank you for using our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

● EF M8BB 21F16G M CU, pipeli ned 8-bit C8051 core with 50 MHz maximum operating frequency.

● Dedicated high frequency driver, makes the start more smooth. ES C maximum speed is 500k e R PM.

● BL Heli-S firmware is designed for superior performance in multirotors, and u ses hardware generated motor

pwm for smooth throttle response and silent operation.

● Damped light does regenerative braking, causing very fast motor retardation, a nd inherently also does active

freewheeling.

● Supports higher K V motor and more power load, more suitable for violent flight of racing drone .

● The code supports regular 1-2ms pulse width P WM input, as well as Oneshot and Multshot . The input signal is

automatically detected by the E S C upon power up.

● Supports Dshot150, Dshot300 and Dshot600.Dshot is digital signal, anti-int erference ability is stronger, and

do not need throttle calibration.

● The silicone twisted-pair of the throttle signal cable increase the service life ,and effectively reduces the crosstalk caused by signal transmission,

and makes flight more stable.

Con. Current

(be well-cooled )

Burst Current

(10S)

Size

(For reference)

Weight

(For reference)

LiPo cells Typical Applications

(For reference)

Model

*Raptor S LI M is using the BL Heli-S firmware; Please contact Flycolor for more information.C-H-40

*Please ensure all solder joints are insulated with heat shrink where necessary.

*All pictures ar e for ref erenc e only

1. Startup power:

Startup power can be set to relative values from 0.031 to 1.5. This is the maximum power that is allowed during startup. Actual applied p ower

depends on throttle input, and can be lower, but the minimum level is a quarter of the maximum level. Sta rtup power also affects bidirectional

operation, as the parameter is used to limit the power applied during direction reve rsal. For lo w rpms, the maximum power to the motor is limited,

in order to facilitate detection of low BE M F voltages. The maximum power allowed ca n be set via the startup power parameter.

2. Motor timing:

Commutation timing can be set to low/mediumlow/medium/mediumhigh/high, that corres pond to 0°/7.5°/15°/22.5°/30° timing advance.

Typicall y a medium setting will work fine, but if the motor stutters it can be beneficial to change timing. Some motors with high inductance can have

a very long commutation demagnetization time. This can result in motor stop or stutter upon quick throttle increase, particularly when r unning at a

low rpm. Setting timing to high will allow more time for demagnetization, and often he lps.

3. Demag compensation:

Demag compensation is a feature to protect from motor stalls caused by long winding demagnetiz ation time after commutation. The typica l

symptom is motor stop or stutter upon quick throttle increase, particularly when running at a low rpm. As mentioned above, setting high

commutation timing normally helps, but at the cost of efficiency.Generally, a higher value of the compensation parameter gives better protection.

If demag compensation is set too high, maximum power can be somewhat reduced.

4. Motor direction:

Rotation direction can be set to fwd/rev/bidirectional fwd/bidirectional rev. In bidirectional mode, center throttle is zero and ab ove is fwd rotation

and below is reverse rotation. When bidirectional operation is selected, progr amming by TX is disabled.

Startup Beep Volume Sets the strength of beep s under normal operation.5. :

Beacon/Signal Volume 6. :

Sets the strength of beeps when beeping beacon beeps. The ES C will start beeping beacon beeps if the throttle signal has been zero for a given

time. Note that setting a high beacon strength can cause hot motors or E SCs!

Programming parameters below can be accessed from the configuration software (B LH eliSuite):

7. Beacon delay: Beacon delay sets the delay before beacon beeping starts.

: If disabled, throttle calibration is disabled. 8. Programming by T X

Please notice that throttle stick can calibrate throttle range only, and can not programming paramenter via throttle stick .

9. Min throttle, max throttle and center throttle:

These settings set the throttle range of the ES C. Center throttle is only used for bidirectional operation. The values given for these settings are for

a normal 1000us to 2000us input signal, and for the other input signals, the values must be scaled.

10.Thermal protection:

Thermal protectio n can be enabled or disabled. And the temperature threshold can be programmed betwee n 80°C and 140°C(from rev16.3).

The E SC measures temperatu re within the MC U and limits motor power if the temperature is too high. Motor power is limited in four steps:

- If the temperature is above threshold , motor power is limited to 75%.

- If the temperature is above threshold 5°C, motor power is limited to 50%.

- If the temperature is above threshold 10°C, motor power is limited to 25%.

- If the temperature is above threshold 15°C, motor power is limited to 0%.

11.Low R P M power pr otect:

Power limiting for low R P Ms can be enabled or disabled. Disabling it can be necessa ry in order to achieve full power on some low kV motors

running on a low supply voltage. However, disabling it increases the risk o f sync loss, w ith the possibility of toasting motor or E SC.

12.Brake on stop:

Brake on stop can be enabled or disabled. When enabled, brake will be applie d when throttle is zero. For nonzero throttle, this setting has no effect.

1. Power up: 2.Throttle signal detected

(arming sequence start):

OK

Once Once

3.Zero throttle detected

(arming sequence end):

Once

4.After this, the

motor will run.

ATTENTION

1.Power up: 2.Throttle signal detected

(arming sequence start):

Once

3.When throttle is above midstick

(measuring max throttle):

4.If throttle is above midstick for 3 seconds:

This beep sequence indicates that max

throttle has been stored

Once

While

measuring

5.When throttle is below midstick

(measuring min throttle):

While

measuring

6.If throttle is below midstick for 3 seconds:

This beep sequence indicates that min

throttle has been stored.

Once

Complete

7.Throttle calibration is complete.

After this, the motor will run.

Once

Example:

Highest tone

Lowest tone

Short beep

Long beep

1.Throttle calibration will be more simple if

using Flight Controller Configurator.

2.When the input signal is Dshot, throttle

calibration is disabled, and the throttle

calibration values are ignored.

● After the E S C connected to the flight system, it will automatically detect the input throttle signals every time it powered on, an d then execute the

corresponding signal-receiving mode.

● User need to calibrate the throttle range when starting to use a new E SC or another transmitter. When the input signal is Dshot, throttle calibration

is disabled.

● When some abnormality occurs in E SC driving the motor or need the motor to reach a higher RP M , user can try to c hange the timing.

● Please contact Flycolor sales or technical support for more information.

251400-1094 , V 1.0