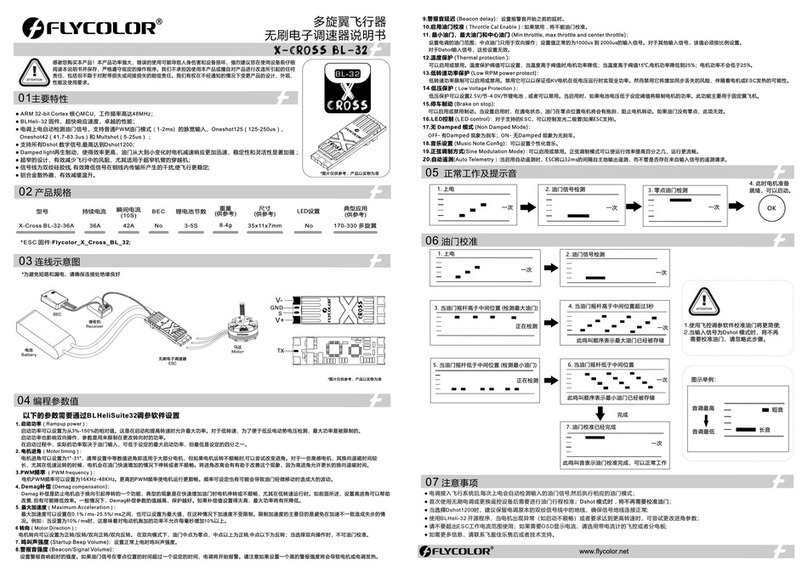

ATTENTION

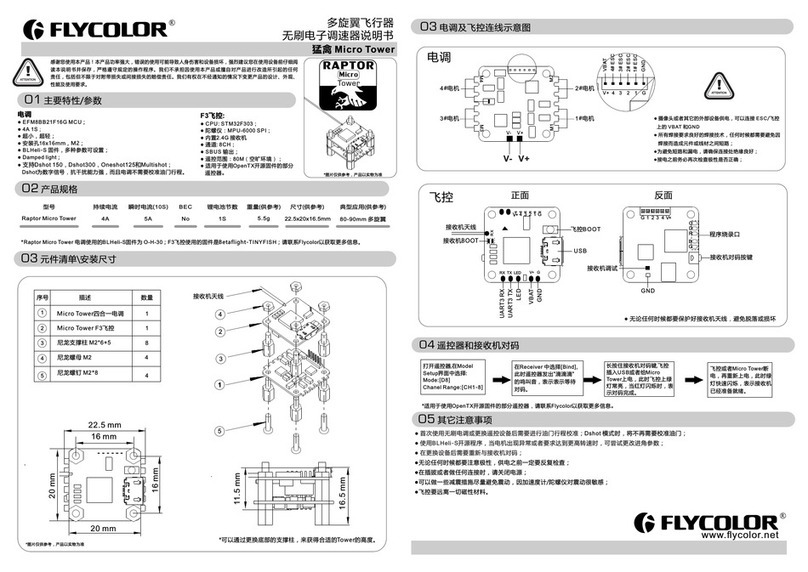

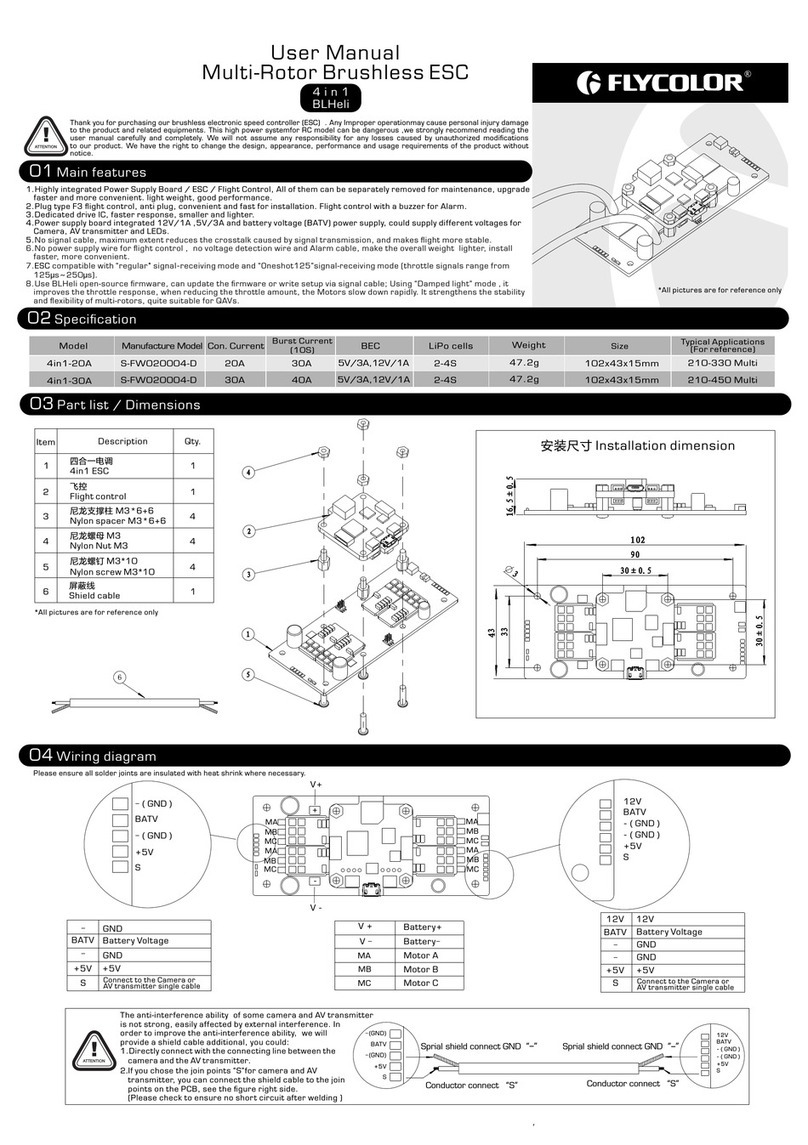

01 Main features

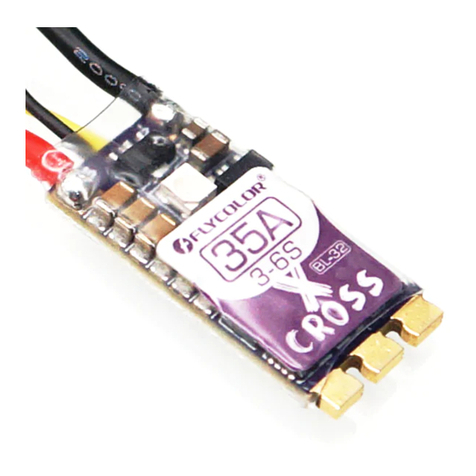

02 Specification

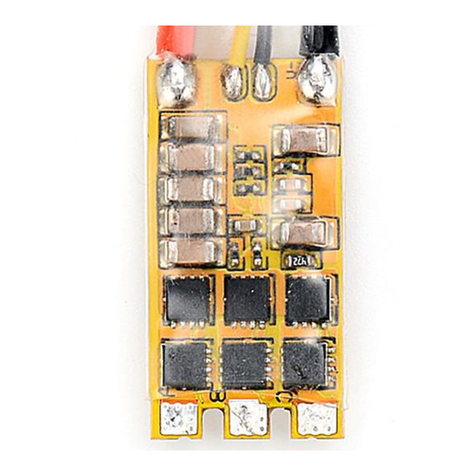

03 Part list / Install Dimensions

BEC

04 Connect diagram

ATTENTION

05 ES C Programming parameters

06 Attention

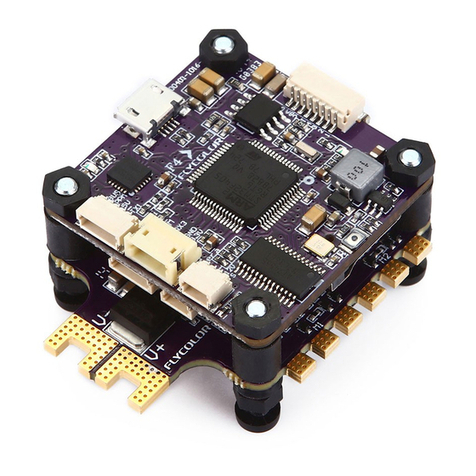

Install Dimensions(mm)

User Manual

Multi-Rotor Brushless ESC

Thank you for using our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

Con. Current Burst Current

(10S)

Size

( For reference )

Weight

LiPo cells Typical Application

( For reference )

Model

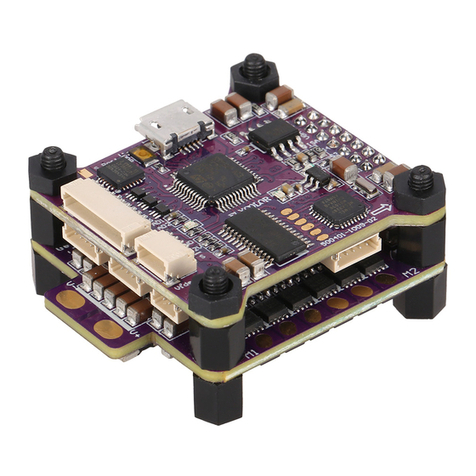

Raptor B L S 4in1 ES C 1

4

4

4

Item Description Qty.

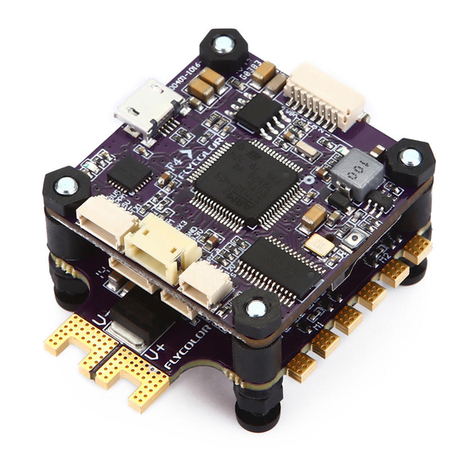

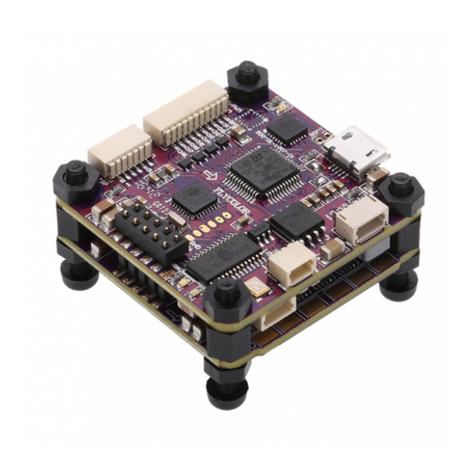

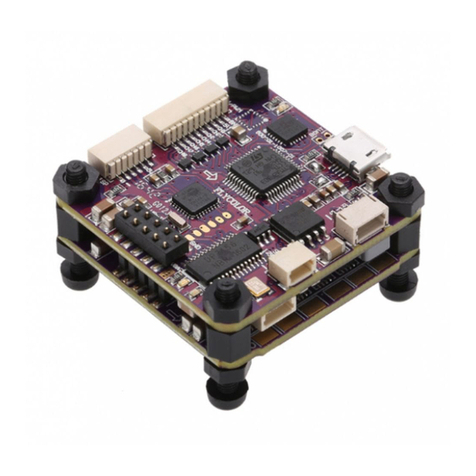

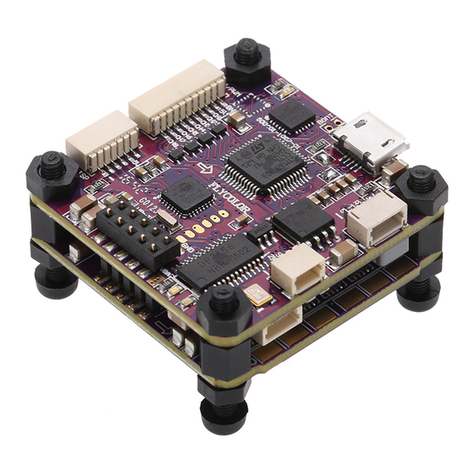

Recommend Raptor S-Towe r 20A F4 flight

controller, assembly w ill be more simple.

ESC addition al provid e:

for connection One 6p cable (6-pin S H1 .0 termina l)

with Flight Controller;

One 16AW G power input cable(XT30 terminal).

*All pictures are for reference only

● All welding requires good welding technology,

short circuit between the element or the wire

should be avoided at any time.

● Please ensure all solder joints are insulated

with heat shrink where necessary.

● Please double-checkthe polarity is correct

before power up.

● VBAT is battery output, make sure your device

operating voltage is matched if you want to use

VBAT.

● EFM8BB21F16G MCU, pipelined 8-bit C8051 core with 50 MHz maximum operating frequency.

ESC maximum speed is limited to 500k eR PM.● Dedicated 3in1 drivers, makes the start more smooth.

Small size ,20A 4in1 E SC,● using cable for quick con nection from E SC to FC .

● ESC firmware: B LHeli-S,F-H-40.

● Silicon spacer for supp orting could reduce the effect of vibration, makes the flight more stable.

BLHeli-S firmware. It is designed for super ior performance in multirotors, and uses hardware generated motor ●

pwm for smooth throttle response and silent operation.

● The code supports regul ar 1-2ms pulse width inpu t, as well as Oneshot125 , Oneshot42 and Multishot .

Supports Dshot150, Dshot300 and Dshot600.Dshot is digital signal, anti-interference ability is stronger, and do●

not need throttle calibration.

● Install holes: 20x20m m,M2.

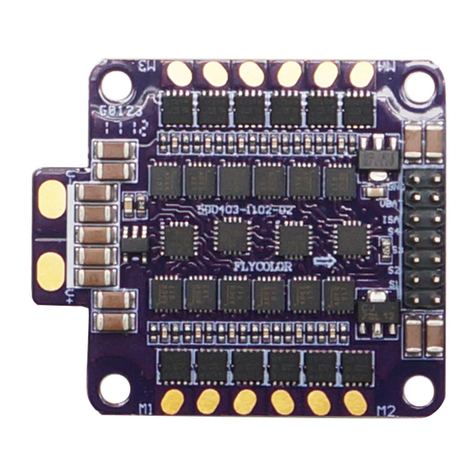

Raptor B L S 4in1-20A 20A 30A 2-4S 31.6x31.2x6mm

6.2g

No

120-180 Multi

1. Startup power:

Startup power can be set to relative values from 0.031 to 1.5. This is the maximum power that is allowed during startup. Actual applied power depends

on throttle input, and can be lower, but the minimum level is a quarter of the maximum level. Startup power also affects bidirectional operation, as the

parameter is used to limit the power applied during direction reversal. For low rpms, the maximum power to the motor is limited, in order to facilitate

detection of low B EMF voltages. The maximum power allowed can be set via the startup power parameter.

2. : Motor timing

Motor timing can be set to low/mediumlow/medium/mediumhigh/high, that correspond to 0°/7.5°/15°/22.5°/30° timing advance.

Typically a medium setting will work fine, but if the motor stutters it can be beneficial to change timing. Some motors with high inductance can have a

very long commutation demagnetization time. This can result i n motor stop or stutter upon quick throttle increase, particularly when running at a low

rpm. Setting timing to high will allow more time for demagnetization, and often helps.

3. Demag compensation:

Demag compensation is a feature to protect from motor stalls caused by long winding demagnetization time after commutation. The typical symptom

is motor stop or stutter upon quick throttle increase, particularly when running at a low rpm. As mentioned above, setting high commutation timing

normally helps, but at the cost of efficiency.

Generally, a higher value of the compensation parameter gives be tter protection. If demag compensation is set too high, maximum power can be

somewhat reduced.

4. Motor direction:

Motor direction can be set to fwd/rev/bidirectional fwd/bidirectional rev. In bidirectional mode, center throttle is zero and above is fwd rotation and

below is reverse rotation.

When bidirectional op eration is selected, programming by TX is disabled.

5. : Startup Beep Volume

Sets the strength of beeps under normal operation.

6. : Beacon/Signal Volume

Sets the strength of beeps when beeping beacon beeps. The ESC will start beeping beacon beeps if the throttle sig nal has been zero for a given time.

Note that setting a high beacon strength can cause hot motors or E SCs !

7. Beacon delay:

Beacon delay sets the delay before beacon beeping starts.

8. Programming by TX: If disabled, throttle calibration is disabled.

Please notice that throttle stick can calibrate throttle range only, and can not programming paramenter via throttle stick .

9. PP M Min throttle, PPM max throttle and PPM center throttle:

These settings set the throttle range of t he ES C. Center thro ttle is only used for bidirectional operation. The values given for these settings are for a

normal 1000us to 2000us i nput signal, and for the other input signals, the values must be scaled.

10.Temperature protection:

Temperature protection can be enabled or disabled. And the temperature thr eshold can be programme d between 80°C and 140°C(from rev16.3).

The ESC measures temperature within the MCU and limits motor power if the temperature is too high. Motor po wer is limited in four steps:

- If the temperature is above threshold , motor power is limited to 75%.

- If the temperature is above threshold 5°C, motor power is limited to 50%.

- If the temperature is above threshold 10°C, motor power is limited to 25%.

- If the temperature is above threshold 15°C, motor power is limited to 0%.

11.Low RPM power protect:

Power limiting for low RPMs can be enabled or di sabled. Disabling it ca n be necessary in order to achieve full power on some low kV motors running

on a low supply voltage.

However, disabling it in creases the risk of sync loss, with the possibility of toasting motor or E SC.

12.Brake on stop:

Brake on stop can be enabled or disabled. When enabled, brake will be applied when throttle is zero. For nonzero throttle, this setting has no effect.

Programming parameters below can be accessed from the configuration software (BLHeliSuite):

Raptor 20A S-Tower 4in1 ESC

*Raptor B L S 4in1-20A ESC is using the F-H-40 BL Heli-S firmware;

4

1

2

3

5

1

2Plastic spacer

3Silicon spacer

4Screw M2*22

5Nylon nut M2 4

31.2mm

20mm

31.6mm

20mm

● User needs to calibrate the throttle range when starting to use a new ESC or another transmitter. When the input signal is Dshot, throttle calibration is

disabled.

● BLHeli-S firmware, please don't flash any other firmware except “F-H-40”. when some abnormality occurs in ESC driving the motor or need the motor to

reach a higher RPM, user can try to change the timing.

● Please do not exceed the ESC current range.

● Observe polarity at all times. Check and double check before applying power.

● Power off before unplugging ,plugging in or making any connections.

●Do everything you can to prevent vibrations.

●Please contact Flycolor sales or technical support for more information.

251400-1101,V 1.0

M3

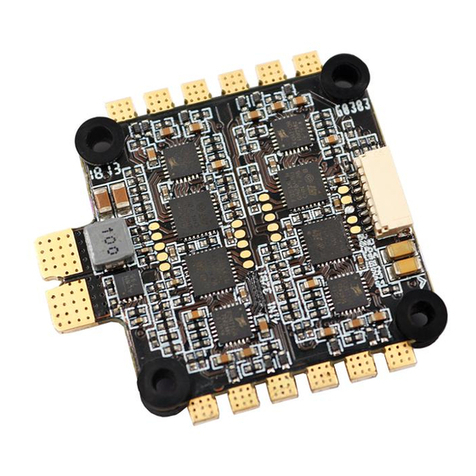

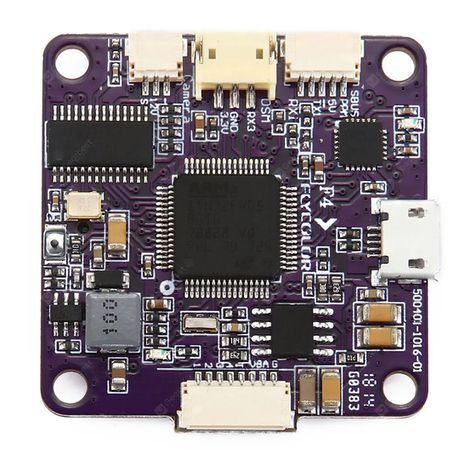

Battery V-

Battery V+

3#Motor

2#Motor

1#Motor

V-

V+

M1 M2

4

3

2

1

V

G

S4

S3

S2

S1

VBAT

GND

4#Motor

M4

1# signal

GND

Battery V+ Output

2# signal

3# signal

4# signal

RAPTOR

S- TOWER

BLS 4in1