LuxaFlex EVO MagnaTrack User manual

Other LuxaFlex Window Blind manuals

LuxaFlex

LuxaFlex LiteRise User manual

LuxaFlex

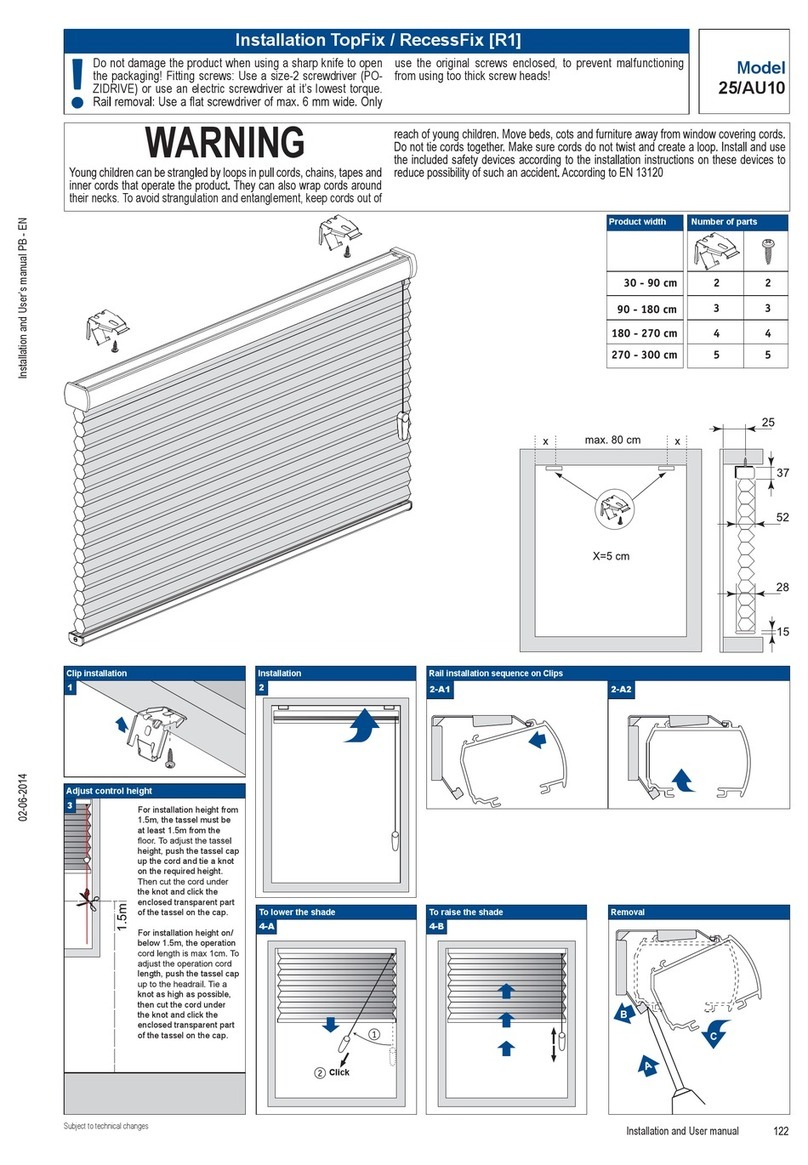

LuxaFlex RecessFix User manual

LuxaFlex

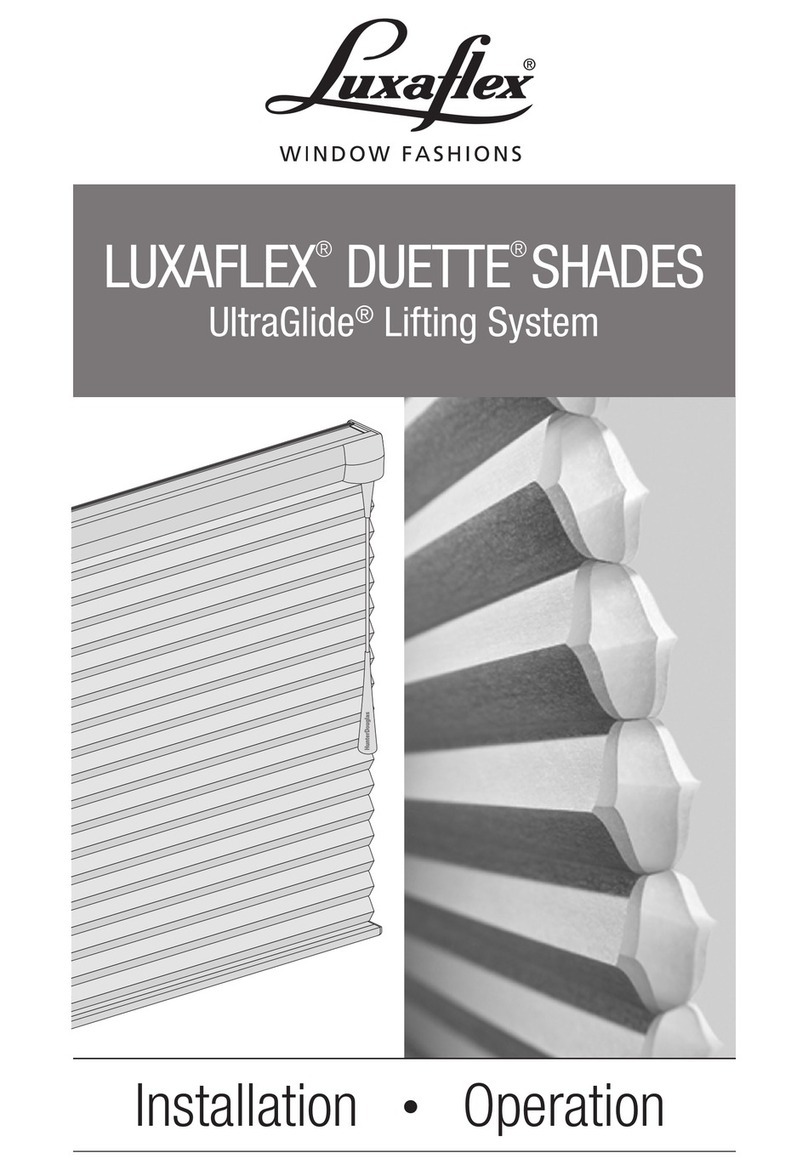

LuxaFlex Duette UltraGlide Guide

LuxaFlex

LuxaFlex Aluminium Venetians User manual

LuxaFlex

LuxaFlex Wood Essence Blinds User manual

LuxaFlex

LuxaFlex Skylight Series User manual

LuxaFlex

LuxaFlex LUMINETTE Dimensional drawing

LuxaFlex

LuxaFlex Roller blinds series User manual

LuxaFlex

LuxaFlex Country Woods Venetians User manual

LuxaFlex

LuxaFlex Twist Series User manual

LuxaFlex

LuxaFlex Timber User manual

LuxaFlex

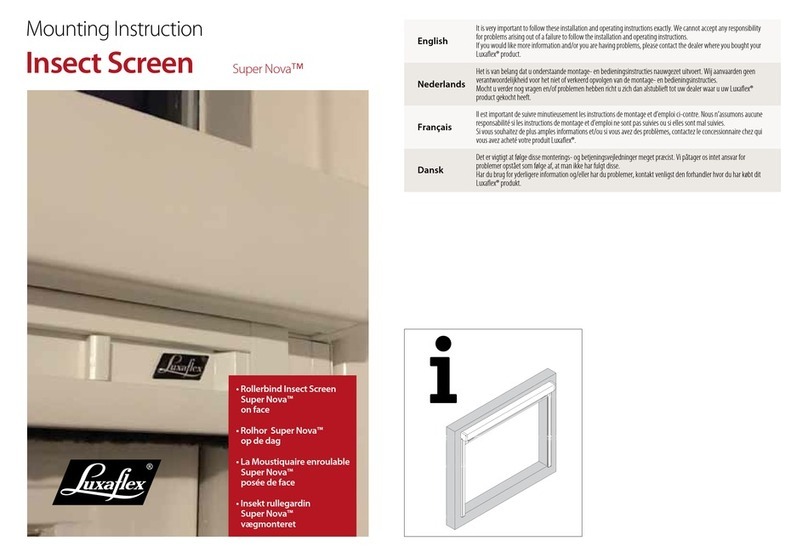

LuxaFlex Super Nova User guide

LuxaFlex

LuxaFlex Silhouette Shades User manual

LuxaFlex

LuxaFlex Silhouette Shadings User manual

LuxaFlex

LuxaFlex 410 User manual

LuxaFlex

LuxaFlex Lumishade User manual

LuxaFlex

LuxaFlex Duette Honeycomb Shades Parts list manual

LuxaFlex

LuxaFlex Timber Venetians User manual

LuxaFlex

LuxaFlex Twist User manual

LuxaFlex

LuxaFlex EasyRise Duette Parts list manual

Popular Window Blind manuals by other brands

weinor

weinor VertiTex ZipR Maintenance Instructions and Directions for use for the end user

Roto

Roto ZAR M R4/R7 Mounting instructions

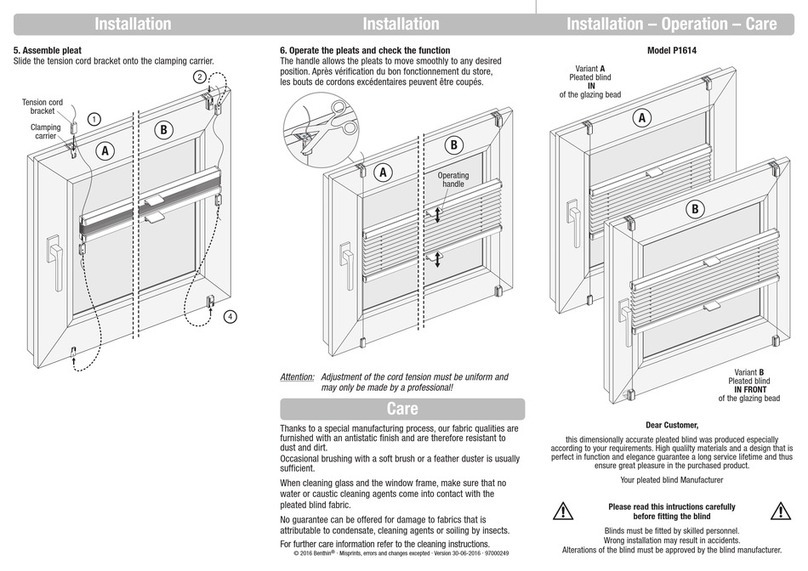

Benthin

Benthin P1614 quick start guide

MDT

MDT KNX Smart 55 BE-JTA5504.01 Technical manual

Victoria M

Victoria M SYSTEM VS 1 Original instructions

SOMFY

SOMFY Movelite WT Series instructions