8.USE WARNINGS

Werecommendfollowingtheindicationsbelowinordertoalwaysworkinsafetyconditions.

·Alltheoperationsmustbecarriedoutcomplyingstrictlywiththesafetyrulesofthecountry

wherethedeviceistobeinstalled.

·ItisSTRICTLYFORBIDDENtosmokeduringtheinstallationoradjustmentoperationsofthe

cuttingunit.

·TheCustomerundertakestocomplywithandmakehisstaffobservealltherulesand

regulationsinforceconcerningsafety,preventionof accidentsandhealthinthework

place.Therefore,theCustomerassumestheresponsibilitytostrictlyfollowalltherulesand

regulationsinforce,aswellasthespecialprovisionsinforceinsportandpublicinstallations

theCustomerdeclarestoknowafterreceivingalltherelativenecessaryinformation.

·Thecuttingunitworksalsowithoutitssafety protectivedevice.Thisprotective

device mustNEVER beremoved.

·Alwayschecktheresistanceofthematerialtobecutandthekindof bladewhichis beingused.

·TheCustomershallequiphisownpersonnelwithalltheindividualsafetyprotectionsfor

theexecutionoftheworks,aswellaswiththeoneswhichmightbeprescribedbythe

Manufacturerduetospecificdangerconditionsoftheplantoroftheareawherethe

personnelmustwork.

·Donot makeanyadjustmentwhilethebladeisworkingorwhiletheelectricplugis

connected.

·Alwayspayattentiontotheelectriccablepositiontopreventitfrombeingcutordamaged

bytheblade.

·ItisallowedtoassemblecuttingunitGRT12Mon machinesO.E.M.on conditionthattheir

originalstructureis notmodified.Otherwise,theintervention mustbecertifiedbyRasor®.

WARNING

3

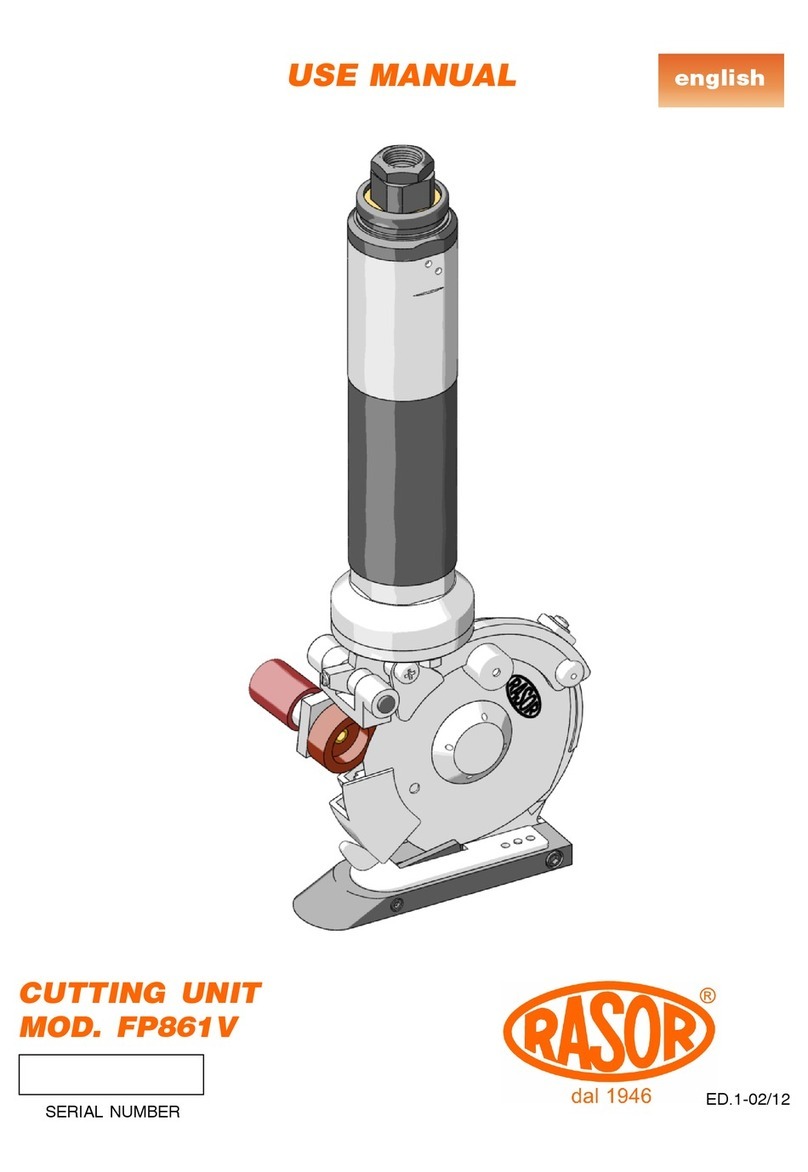

9.ELECTRICCONNECTION

B

A

B

Firstlymakesurethatthelinesareabletosupplythecuttingunitwithpowercorrectly,

incompliancewiththesafetyrules(forthefeaturerequiredseepar.5).

Wesuggestinstallingamagnetothermicsafetydevicebeforethecuttingunitandcheckthat

thegroundcircuitis effective.Beforeworkingonthefeedingcablepulltheplugout.Check

thatelectricconnectionsandprotections correspondtothedrivingforceandtheplatedata

values(voltageandcurrent),requiredbythedifferentelectriccircuits.ByreferringtotheCEI

11-27/1standardall theworkscarriedoutbymeans ofelectriccurrentmustbeperformed

bystaffprovidedwithall thedevicesrequiredbytheabove-mentionedstandard.Forthe

workscarriedoutundervoltage,itisnecessarythattheemployercertifiesthestaffsuitability,

afteratrainingperiod.ThecuttingunitGRT12Missupplied

withelectriccableconnectedtotheconnectorblocklocated

nearthemotor.Theusermustconnectthecuttingunittothe

mains(thecablecomplieswiththeCEI20-22IIIStandard).

Neverchangethelengthofthesuppliedcable.Ifnecessary,use

alongercableandreplacetheonesupplied.Toconnectthe

newcableopencover“A”byunscrewingthe4cross-slotted

screws“B”(seepicture3).Connectthephasecableto the

terminalboard.Theminimum sectionoftheconnectingcables

mustbedeterminedbytheoperatorinchargeoftheinstallation.

WerecommendusingIMQapprovedsafetycablesandsockets.

Checktheconnectionbyenablingthecuttingunitandverify

therotationdirection.Thecuttingunitis providedwithearthing

(yellow-greencable).Possiblefaultyearthingconnectionsmay

Enfocus Software - Customer Support

EN

24