MX-FNX9 SPECIFICTIONS 2 – 2

*4: Thick paper (In the cover paper mode, allowable only 2 (in total of the front cover paper and the back cover paper) + plain paper.))

*5: Follows the paper type registration setting.

B. Allowable load quantity for each size

*1: 250 sheets or height of 35.5mm or less

*2: 500 sheets or height of 71mm or less

*3: Up to 10 envelopes can be loaded on the load tray.

*4: 250 sheets or 30 sets, or height of 35.5mm or less

*5: 500 sheets or 30 sets or height of 71mm or less

*6: Similarly with plain paper, the load capacity of thin paper, heavy paper, and glossy paper is limited to the earliest reach of the above number

of sheets or the limited height.

*7: 100 sheets or height of 35.5mm or less

2. MX-PNX1A/B/C/D

*1: Auto switching: 2 holes/3 holes

Function/Mode Non-offset Offset Staple

Paper size Plain paper

(60 - 105g/m2 paper)

A3W 250 *1 No No

A3 250 *1 250 *1 250 *4

B4 250 *1 250 *1 250 *4

A4 500 *2 500 *2 500 *5

A4R 500 *2 500 *2 500 *5

B5 500 *2 500 *2 500 *5

B5R 500 *2 No No

A5R 500 *2 No No

12 x 18 250 *1 No No

11 x 17 250 *1 250 *1 250 *4

8.5 x 14 250 *1 250 *1 250 *4

8.5 x 13.5 (216 x 343) 250 *1 250 *1 250 *4

8.5 x 13.4 (216 x 340) 250 *1 250 *1 250 *4

8.5 x 13 (216 x 330) 250 *1 250 *1 250 *4

8.5 x 11 500 *2 500 *2 500 *5

8.5 x 11R 500 *2 500 *2 500 *5

7.25 x 10.5R 500 *2 No No

5.5 x 8.5R 500 *2 No No

8K 250 *1 250 *1 250 *4

16K 500 *2 500 *2 500 *5

16KR 500 *2 No 500 *5

Special (Custom) 250 *1 No No

Envelope 10*3 No No

Thin paper 500 *6 500 *6 500 *6

Thick paper 500 *6 500 *6 Cover only

gloss paper A4/8.5 x 11 500 *6 500 *6 No

Tab paper A4/8.5 x 11 100 *7 No No

Label paper A4/8.5 x 11 100 *7 No No

OHP A4/8.5 x 11 100 *7 No No

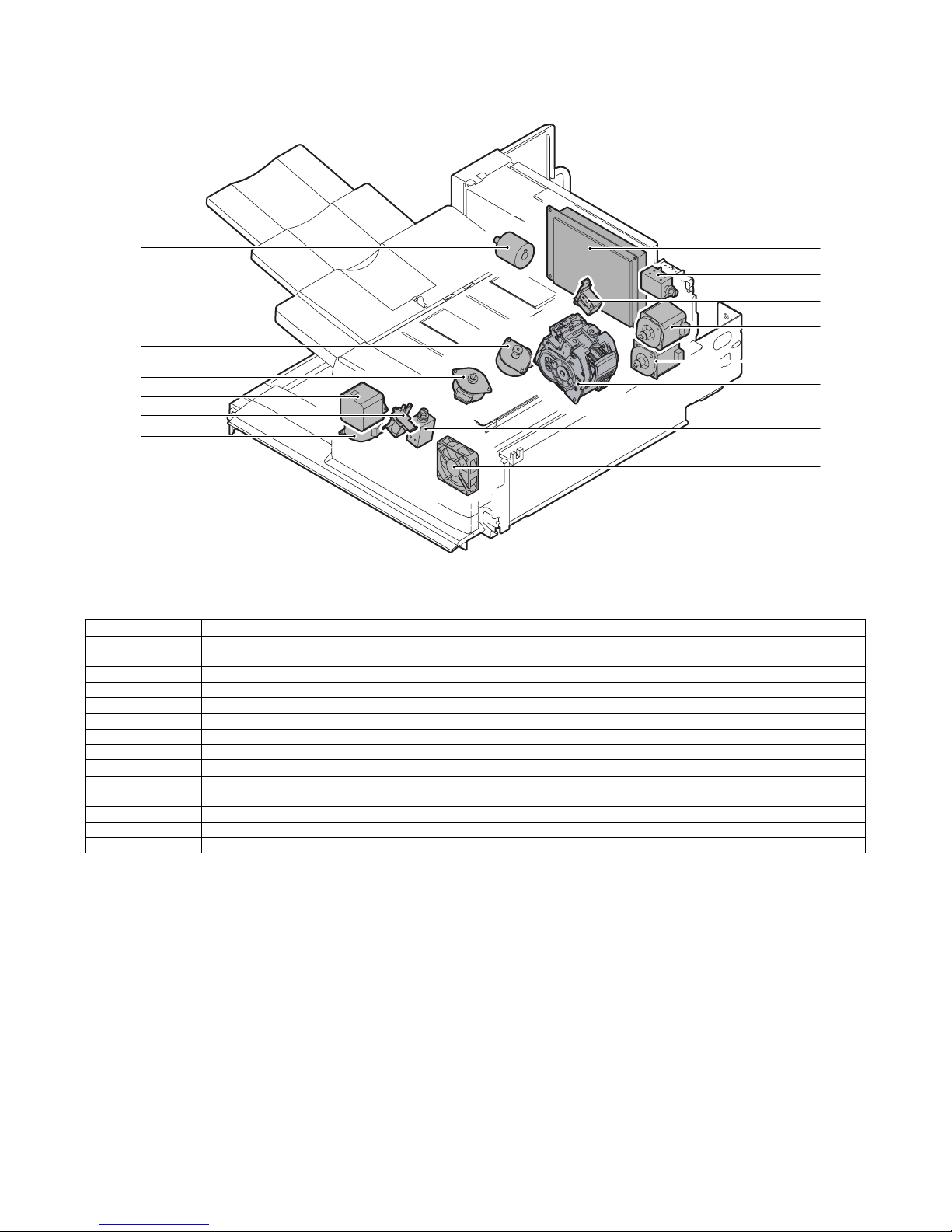

Type Punch unit for the inner finisher

Punch type 2 holes / 3 holes / 4 holes / 4 holes (wide)

A punch unit that provides all of these 4 types can be installed.

Transport speed 23, 27, 35, 45 PPM

Transport reference Center reference

Punch dust full detection YES (Lever system)

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m2(16 to 28 lbs)

Thin paper: 55 to 59g/m2(15 to 16 lbs)

Heavy paper: 106 to 209g/m2(28 to 56 lbs)

Punchable paper size 2 holes

(MX-PNX1A)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 8K, 16K, 16KR

3 holes *1

(MX-PNX1B)

3 holes: A3, A4, 11" x 17", 8.5" x 11"

2 holes: 8.5" x 14", 8.5" x 13", 8.5" x 11"R

4 holes

(MX-PNX1C)

A3, A4

4 holes (wide)

(MX-PNX1D)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

Power source Supplied from the inner finisher. (DC24V, DC5V)

External dimensions (W x D x H) 105 x 518 x 170 (mm), 4 9/64 x 20 25/64 x 6 45/64 (inch)

Weight Approx. 3.5kg (7.7 lbs)

Packaged items Parts for mounting, instructional label for punch direction, instructional label for garbage pickup, installation cautionary note