7

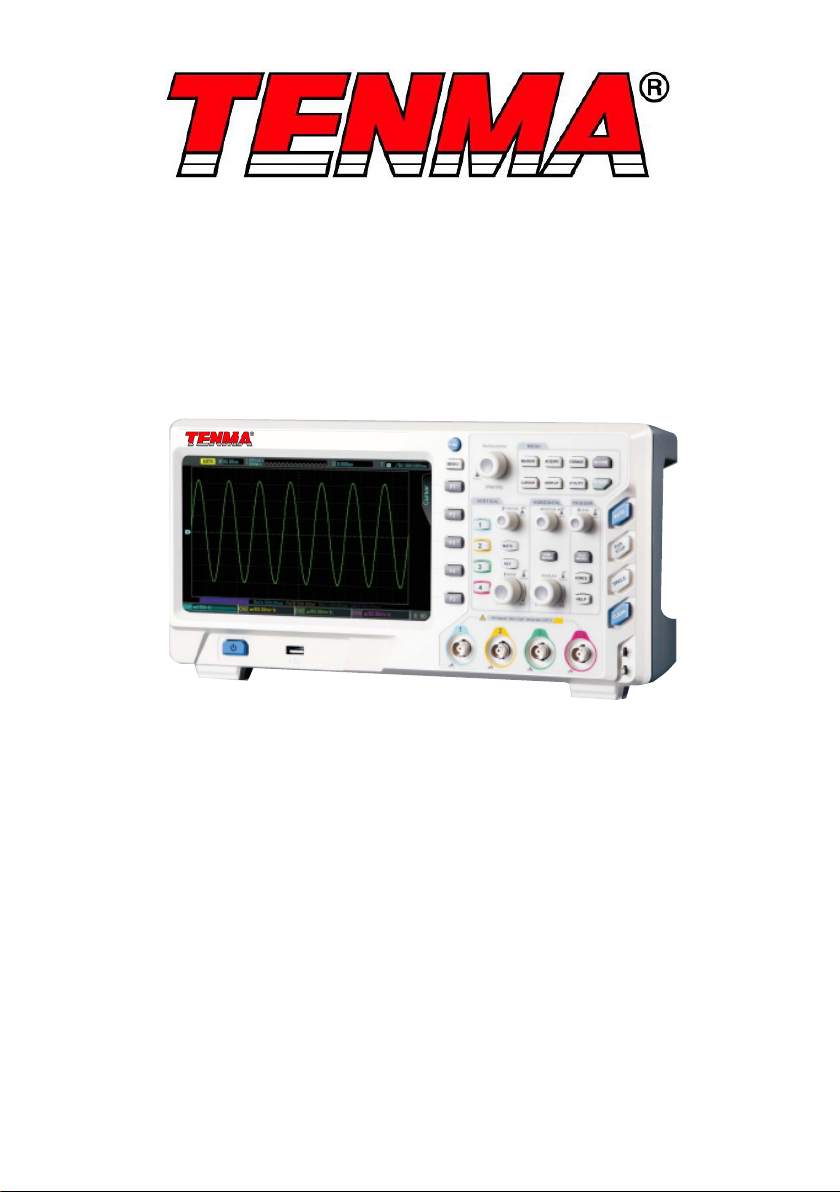

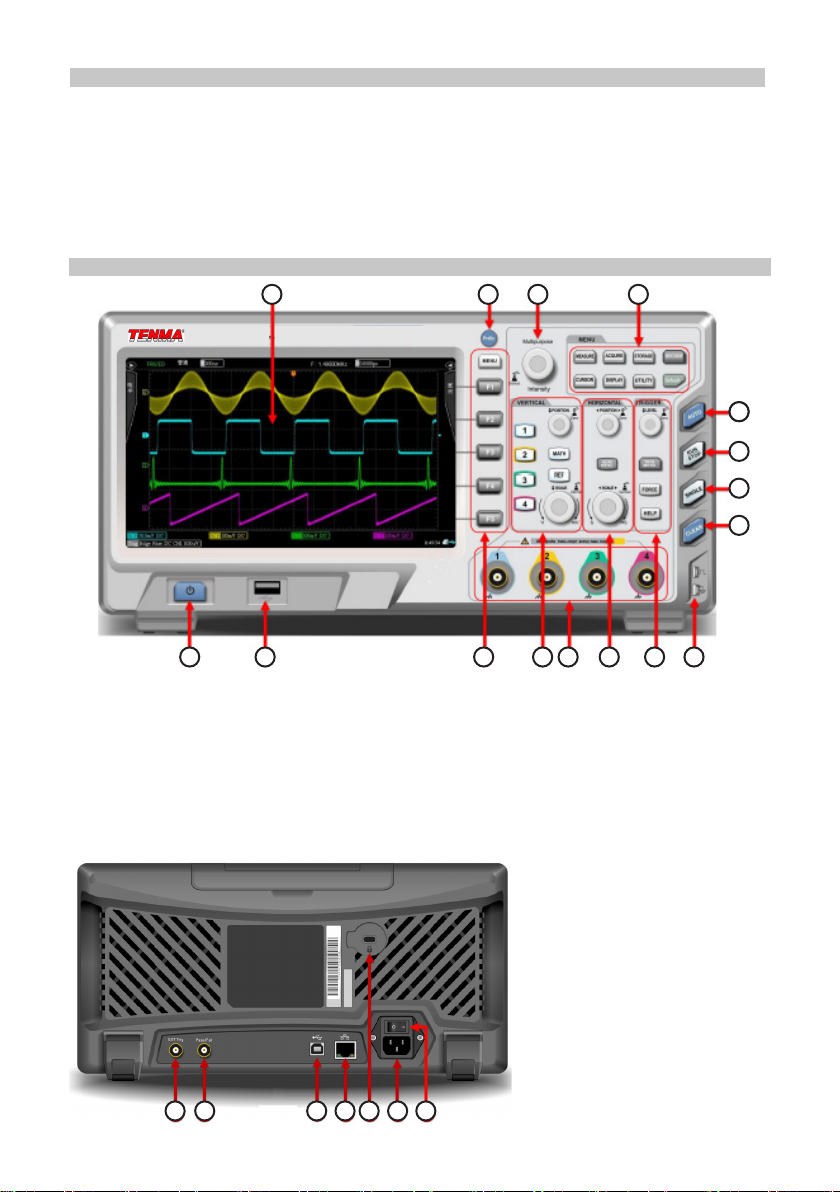

1. USB Device Identication: This icon will be displayed when an USB storage

device is connected.

2. Trigger Status Identication: Include TRIGED (has been triggered), AUTO,

READY, STOP, and ROLL (rolling)

3. Timing Scale: Indicates the amount of time represented by one square, which can

be adjusted by the horizontal scale control.

4. Sampling Rate/Acquisition Mode: Indicates the current sampling rate and storage

depth.

5. Horizontal Displacement: Shows the horizontal displacement, which can be

adjusted by turning the horizontal position control. Pressing the control returns the

displacement back to 0.

6. Trigger Status: Displays trigger source, type, slope, coupling, level, etc.

• TRIGGER SOURCE: There are seven states: CH1~CH4, AC Line, EXT, and EXT/5.

Note: CH1~CH4 will each be displayed a different trigger colour.

• TRIGGER TYPE: The types are edge, pulse width, video, slope, and advanced

trigger.

• TRIGGER SLOPE: The types are rising, falling, and rising/falling.

• TRIGGER COUPLING: The types are DC, AC, high frequency, low frequency and

noise.

• TRIGGER LEVEL: Indicates the current trigger level value, can be adjusted with the

trigger level control.

7. CH1 Vertical Identication: Displays CH1 activation state, channel coupling,

bandwidth limit, vertical prole, and probe attenuation coefcient.

• CHANNEL ACTIVATION STATE: When the background colour is consistent with

the channel colour, the channel is activated. Press CH1~CH4 to open/close the

corresponding channel.

• CHANNEL COUPLING: Includes DC, AC, and grounding.

• BANDWIDTH LIMITATION: When the bandwidth limit function is turned on, a BW

icon will appear in the display.

• VERTICAL PROFILE POSITION: When CH1 is activated, the vertical prole can be

adjusted with the vertical scale control.

• PROBE ATTENUATION FACTOR: Displays CH1 probe attenuation coefcient:

0.001X, 0.01X, 0.1X, 1X, 10X, 100X, and 1000X

8. CH2 Vertical Identication: Same as 7 but for CH2

9. CH3 Vertical Identication: Same as 7 but for CH3

10. CH4 Vertical Identication: Same as 7 but for CH4

11. Operation Menu: Displays the current operation menu. Use F1 ~ F5 to navigate

through menu contents

12. Analogue Channels: Displays CH1~CH4 waveforms with matching tag and

waveform colour.