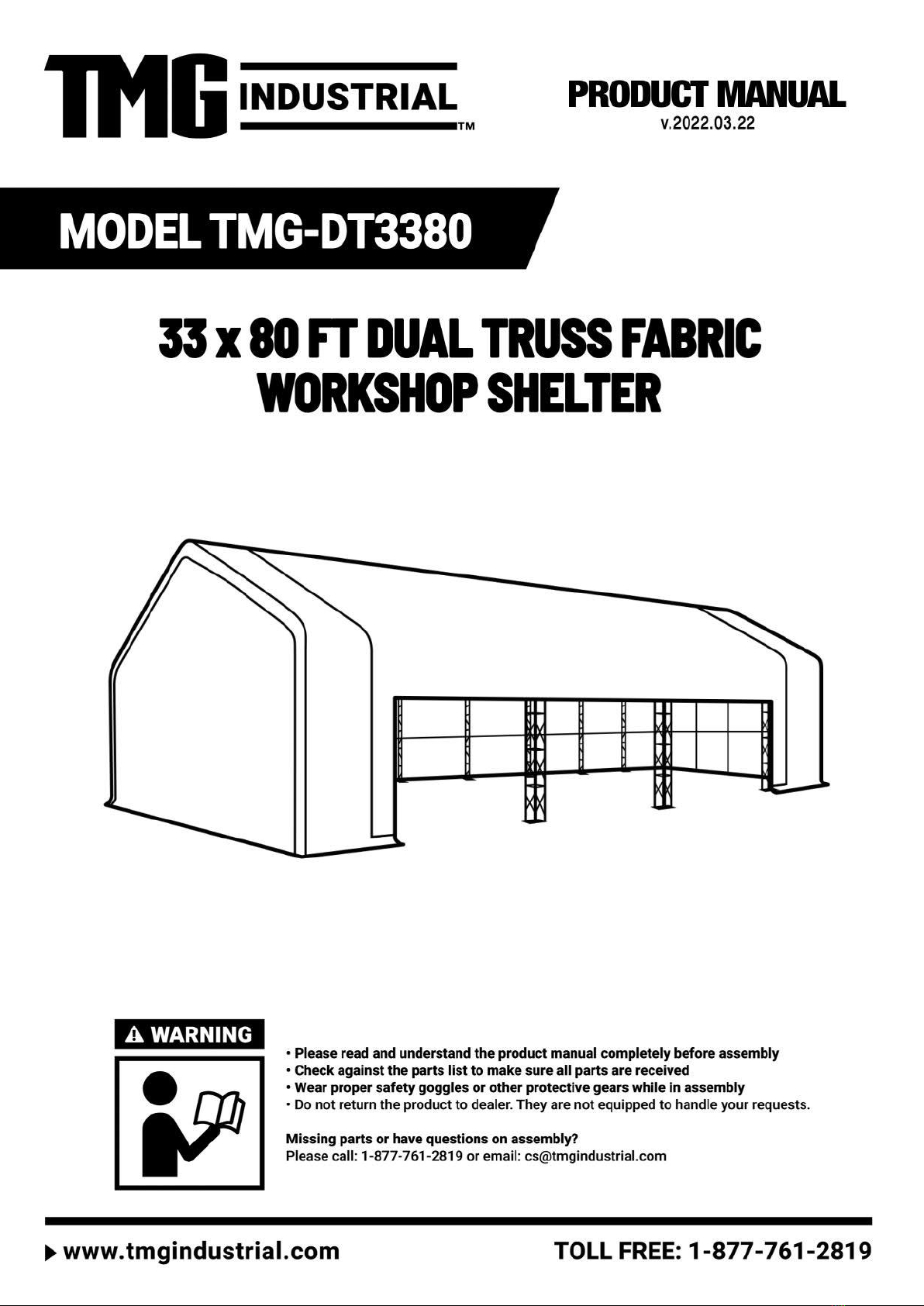

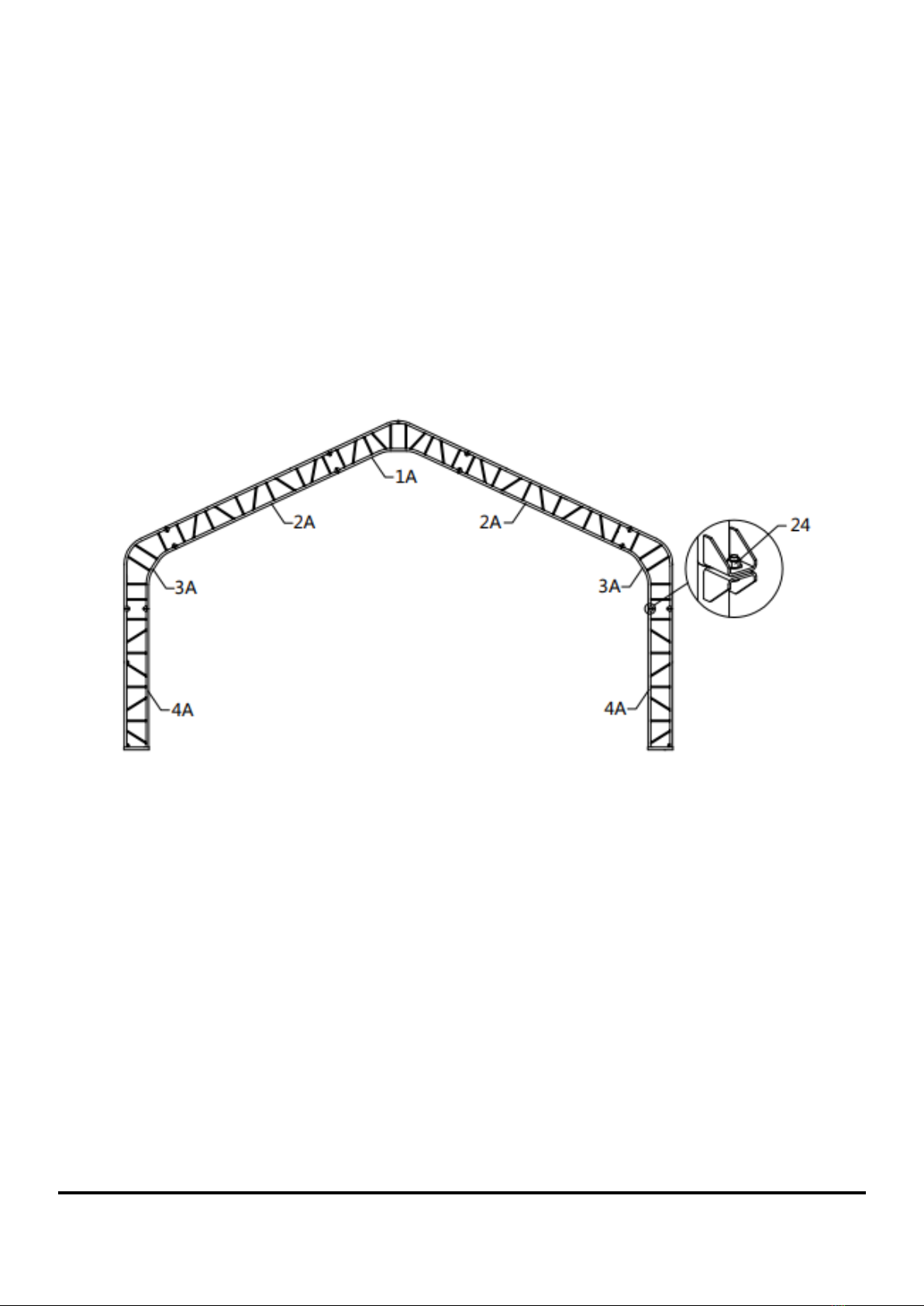

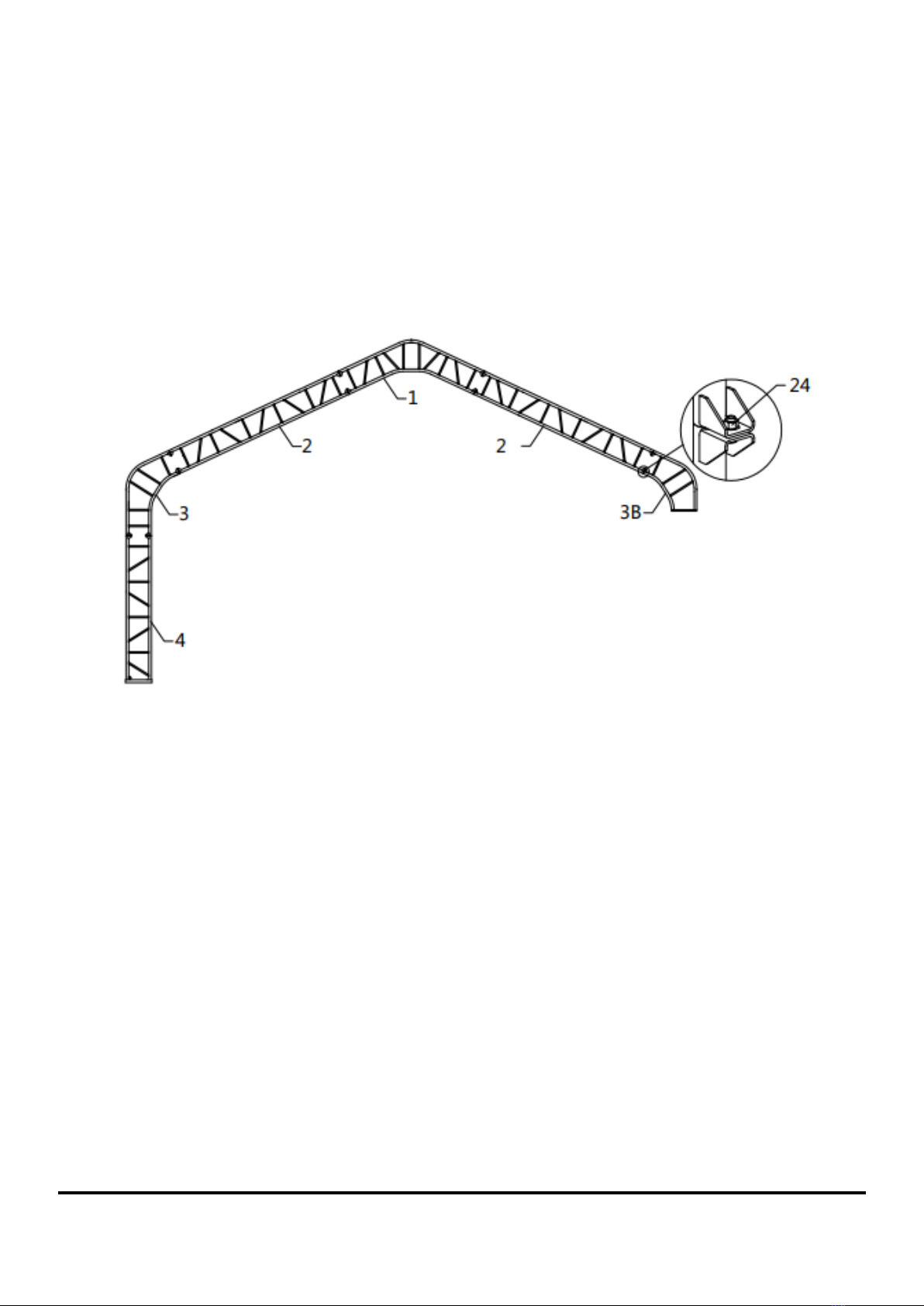

TMG TMG-DT3380 User manual

Other TMG Shelter manuals

TMG

TMG TMG-DT2030-PRO User manual

TMG

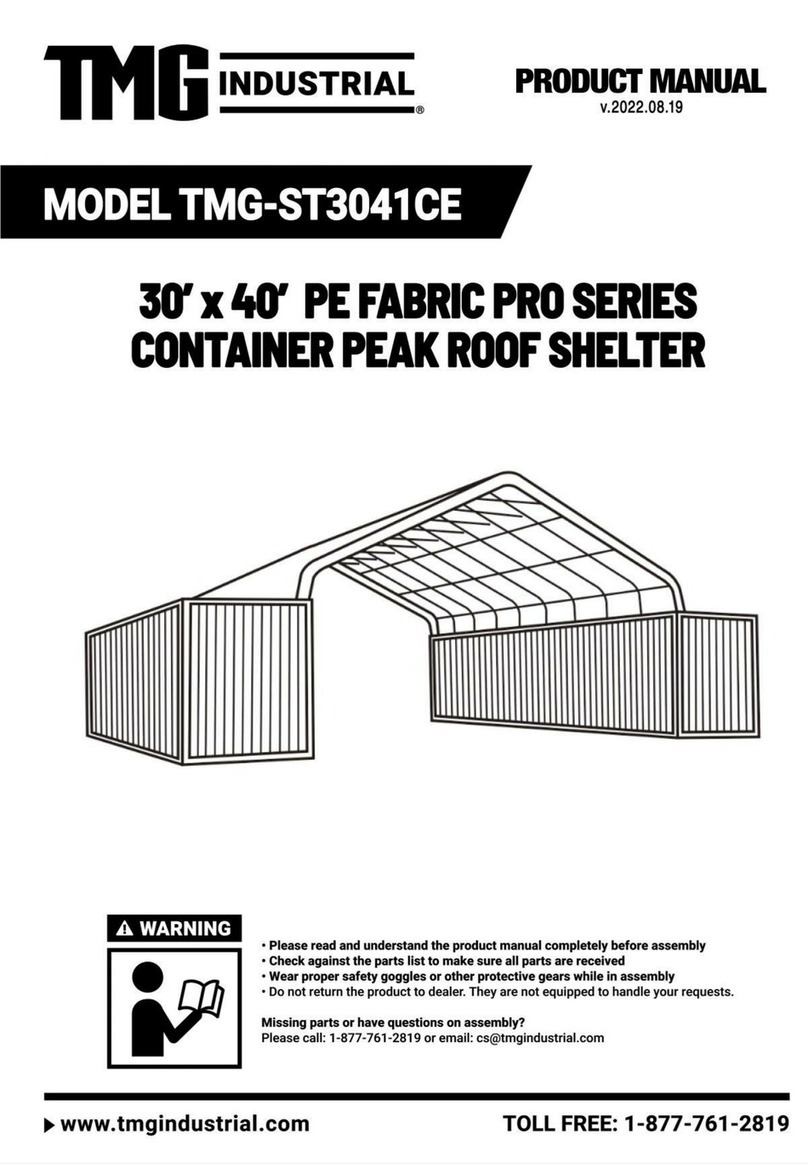

TMG TMG-ST3040C User manual

TMG

TMG TMG-ST2041V User manual

TMG

TMG TMG-CP1220 User manual

TMG

TMG PRO Series User manual

TMG

TMG TMG-DT4041CF User manual

TMG

TMG TMG-MSC2030F User manual

TMG

TMG PRO Series User manual

TMG

TMG TMG-ST2031V User manual

TMG

TMG DUAL TRUSS PRO Series User manual

TMG

TMG TMG-ST3040-1.0 User manual

TMG

TMG TMG-ST4061E User manual

TMG

TMG TMG-ST4081E User manual

TMG

TMG TMG-DT4041CG User manual

TMG

TMG ST3080V-1.0 User manual

TMG

TMG TMG-CP2030F-1.0 User manual

TMG

TMG TMG-CRS1040 User manual

TMG

TMG PRO Series User manual

TMG

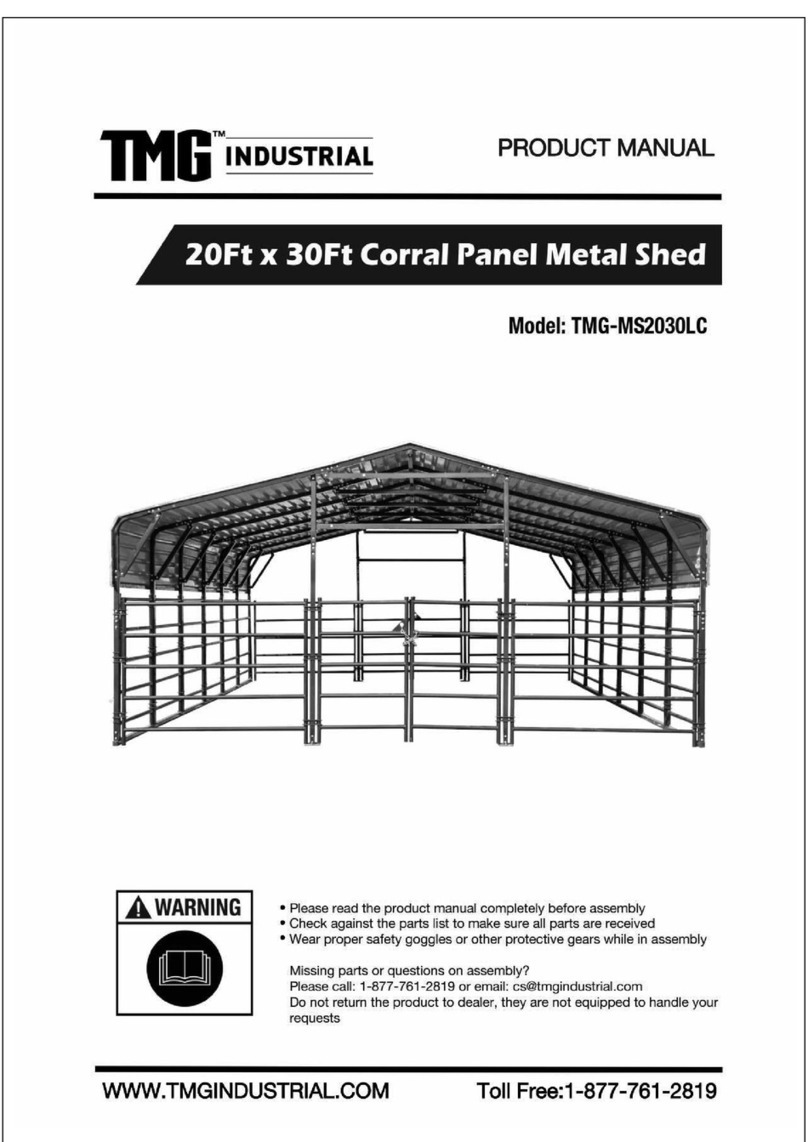

TMG TMG-MS2030LC User manual

TMG

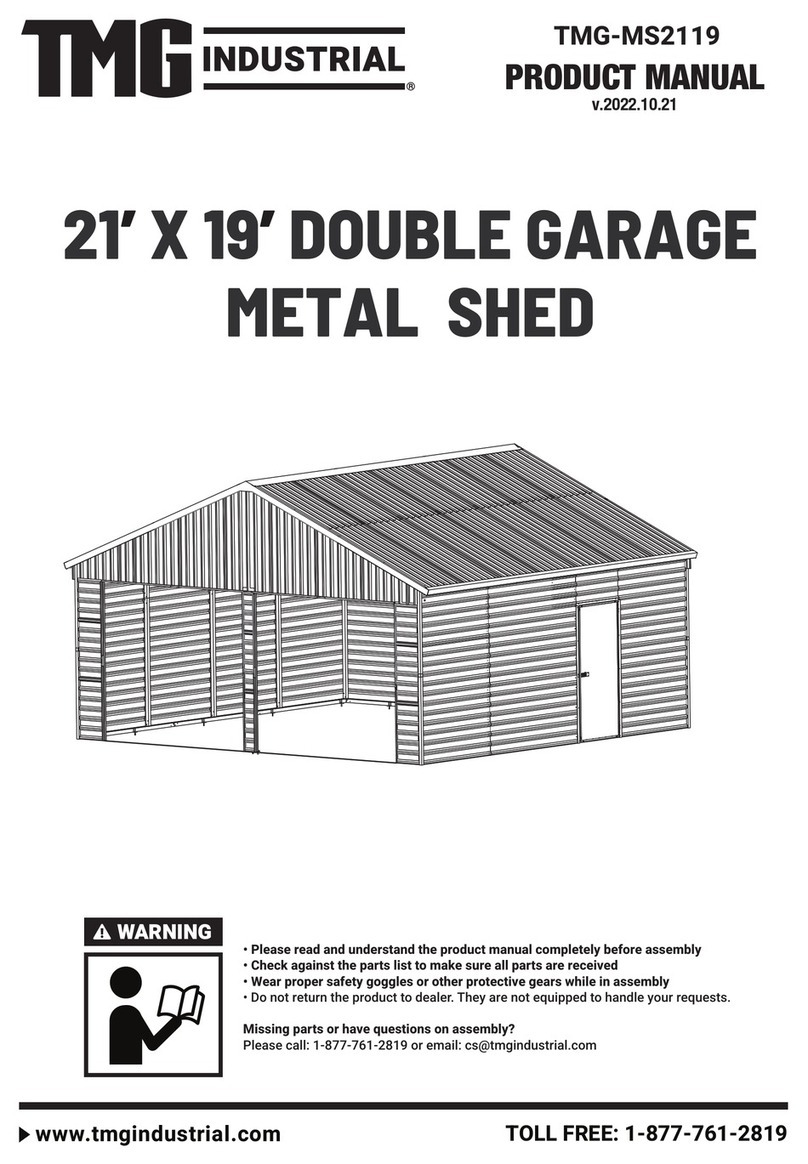

TMG TMG-MS2119 User manual

Popular Shelter manuals by other brands

Shelters4Less

Shelters4Less SR1551 Assembly instructions

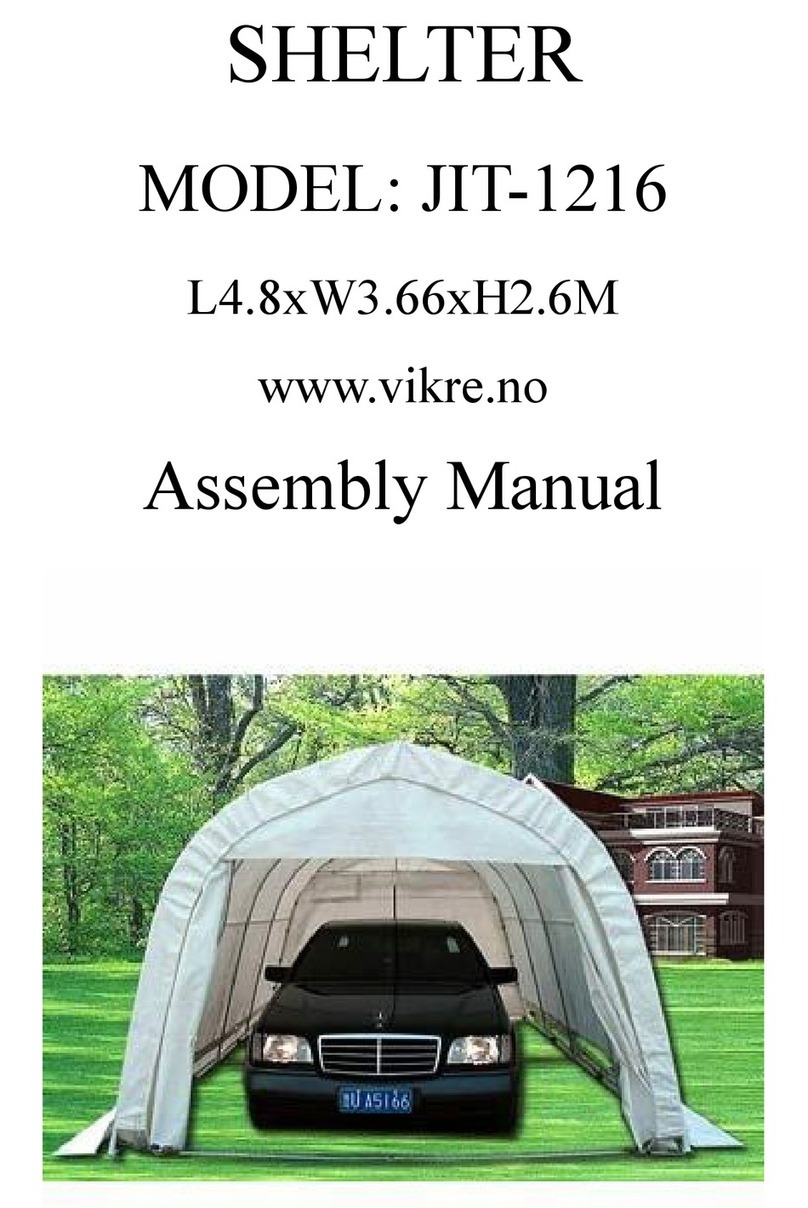

Vikre Handel AS

Vikre Handel AS JIT-1216 Assembly manual

VARNA buildings

VARNA buildings C2020H instruction manual

Storage Canopy

Storage Canopy C3340R Assembly instructions

Frabill

Frabill ICE HUNTER 195 instruction manual

Shelters4Less

Shelters4Less SR1588 Assembly instructions

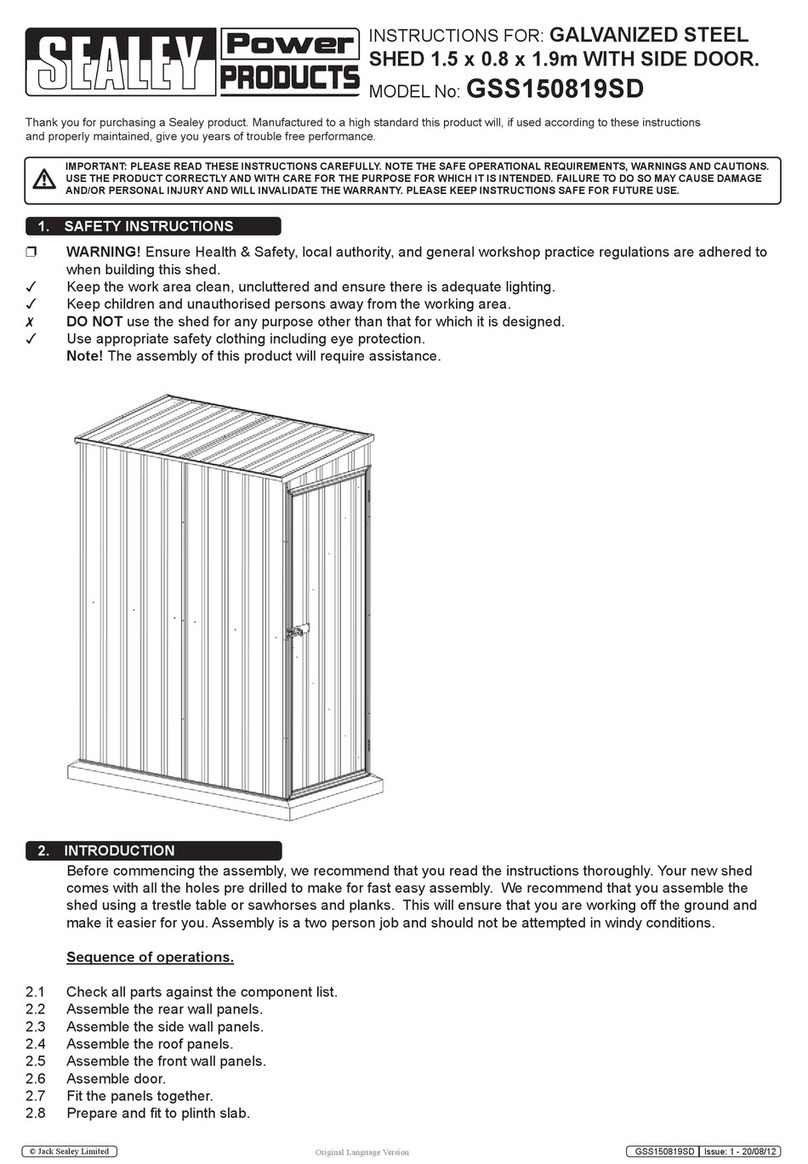

Sealey

Sealey Power Products GSS150819SD instructions

Crivit

Crivit 104155 Operation and safety notes

No Butts Bin

No Butts Bin SR1558-F Assembly instructions

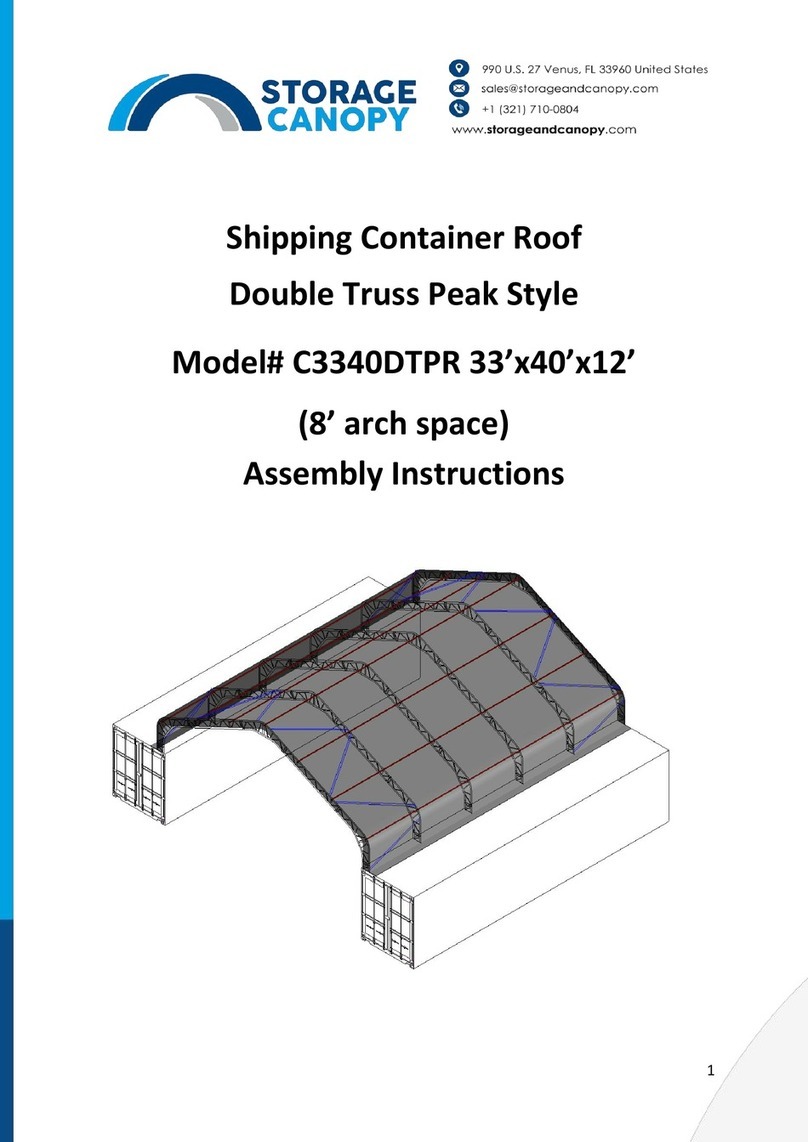

Storage Canopy

Storage Canopy C3340DTPR Assembly instructions

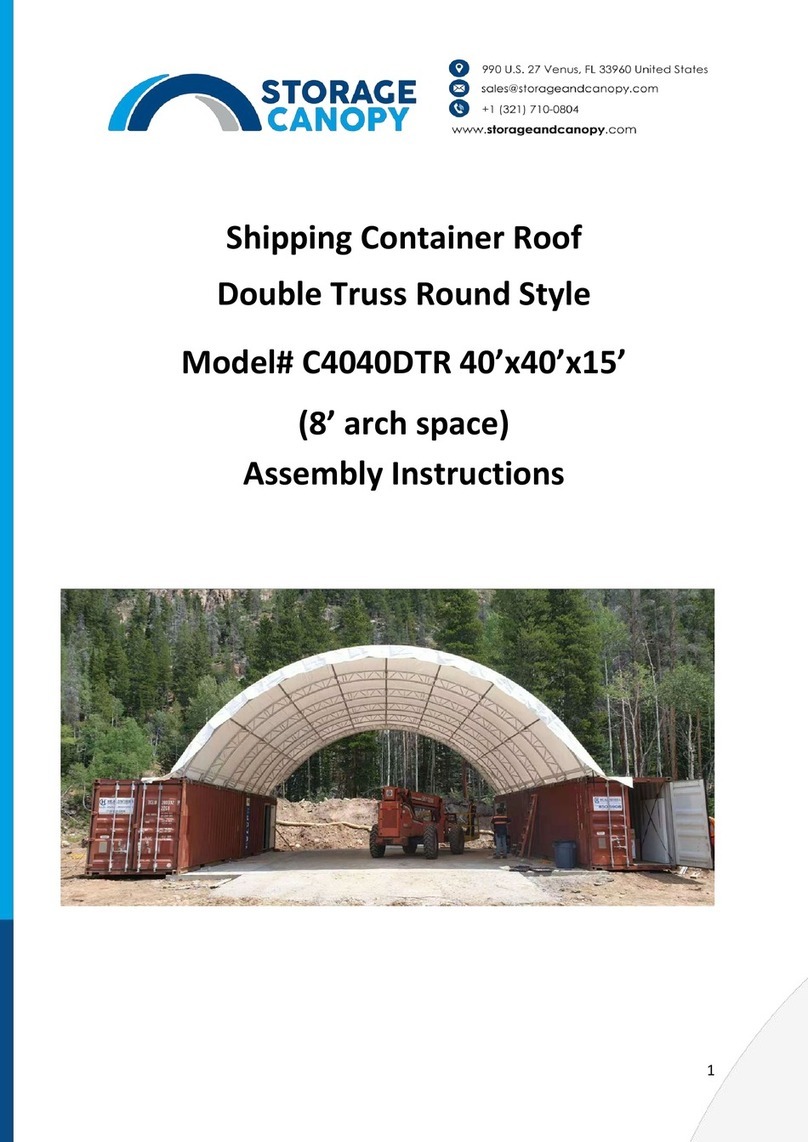

Storage Canopy

Storage Canopy C4040DTR Assembly instructions

NBB

NBB SR8062-F Assembly instructions