3

Installation Plastic Laminate Restroom Partitions, Ceiling-Hung — Series 600

Bradley • HDWL-INSTR-003 Rev. D; ECN 13-14-030B 8/29/2013

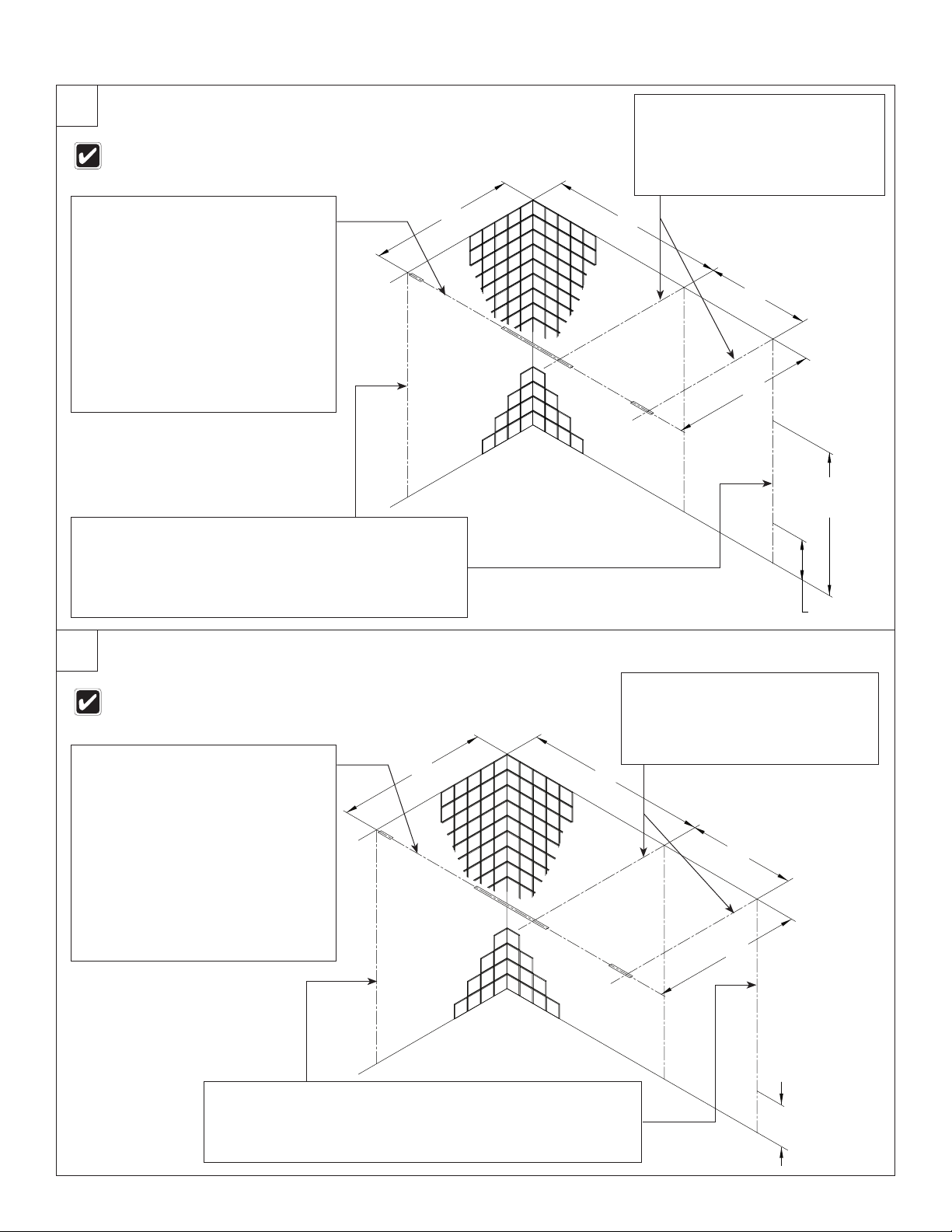

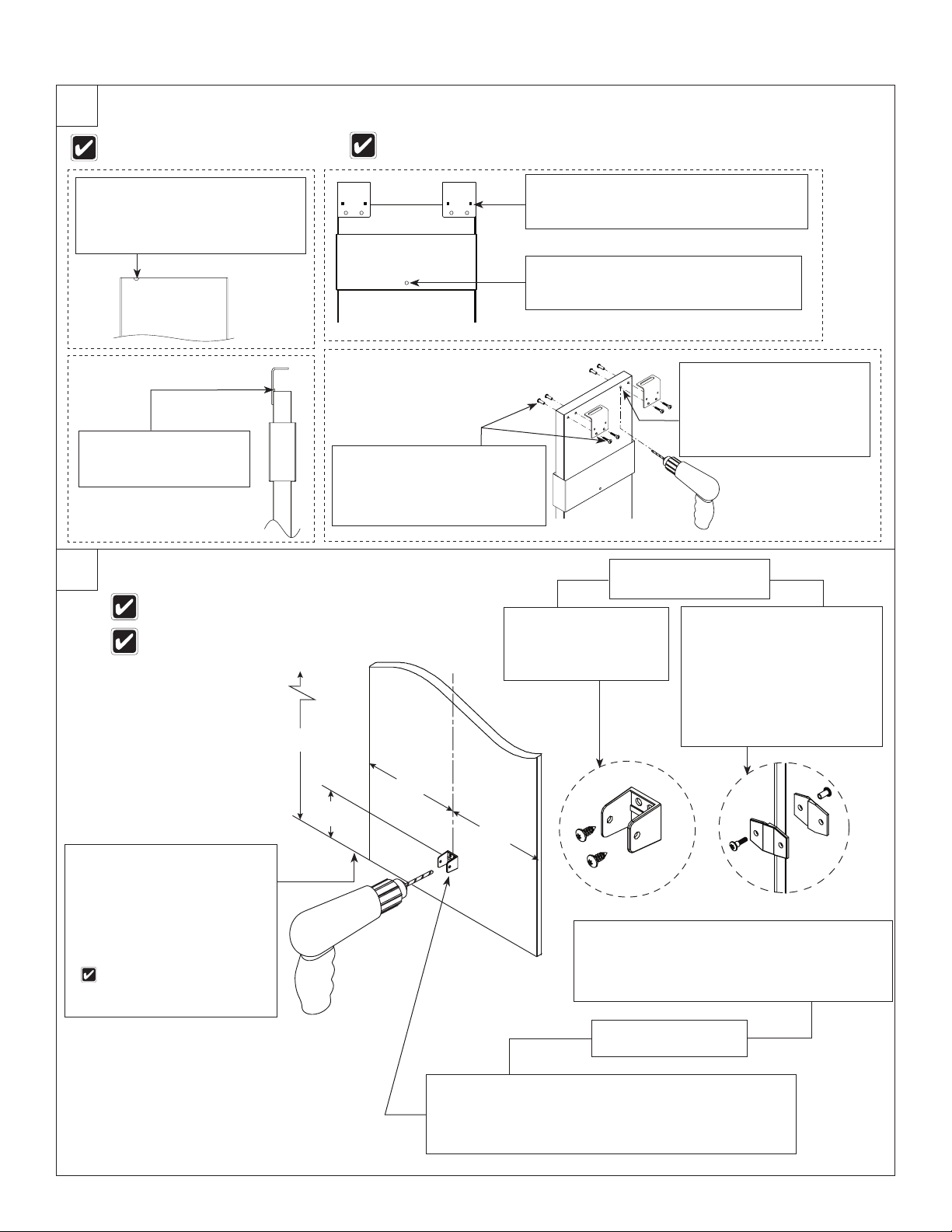

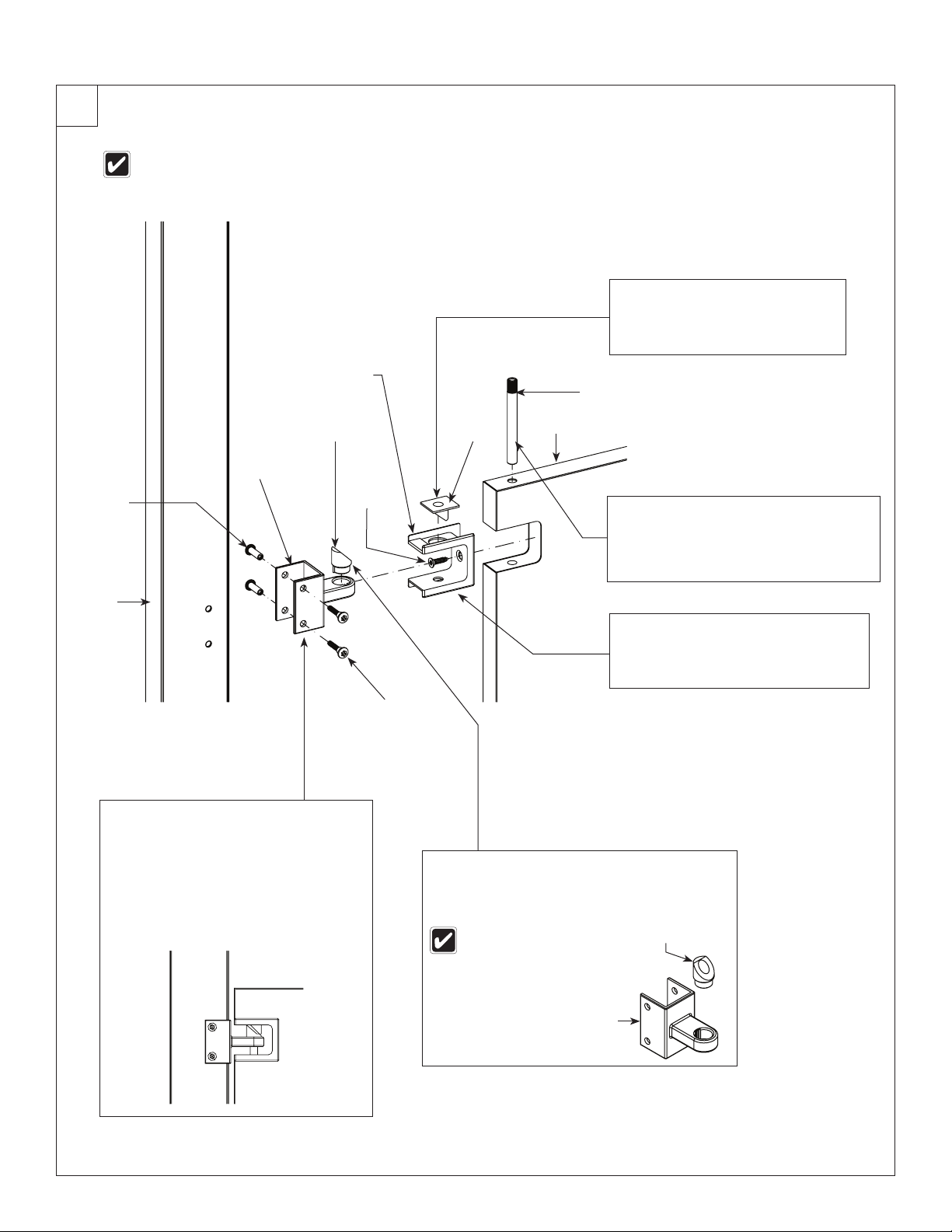

1Layout Dimensions - Stirrup Bracket (Standard)

When installing the partition components, consult

the applicable Mills Partition submittal drawing

for compartment layout dimensions.

When installing the partition components, consult

the applicable Mills Partition submittal drawing

for compartment layout dimensions.

Pilaster centerline: Measure from

the back wall forward to the face of the

compartment, subtract ⁵⁄₈" (16mm) and

mark this location on the ceiling (“A”).

Mark the same measurement on the

opposite end of your layout (“A1”) and

draw a straight line connecting both

marks.

FOR FREESTANDING (FS)

PARTITIONS: Refer to submittal

drawings and determine the

approximate location of the outside

panels. Establish dimensions “A” and

“A1” as explained above.

A

Panel centerline: Measure the stall

width across the back wall and

place a mark at the top of the rear

wall (“B”). Repeat this step for each

panel, starting each measurement

from the last panel centerline (“B1”).

B

Stirrup brackets: Draw a plumb line on all walls from each

pilaster and panel centerline. From the highest point in the

room, measure 18" (457mm) and 64" (1626mm) from the floor

and place a mark on the pilaster/panel plumb line. These marks

represent the hole center line of the stirrup brackets. Use a

level to transfer that mark to all other plumb lines (“C”).

C

*

"C"

*

"C"

C

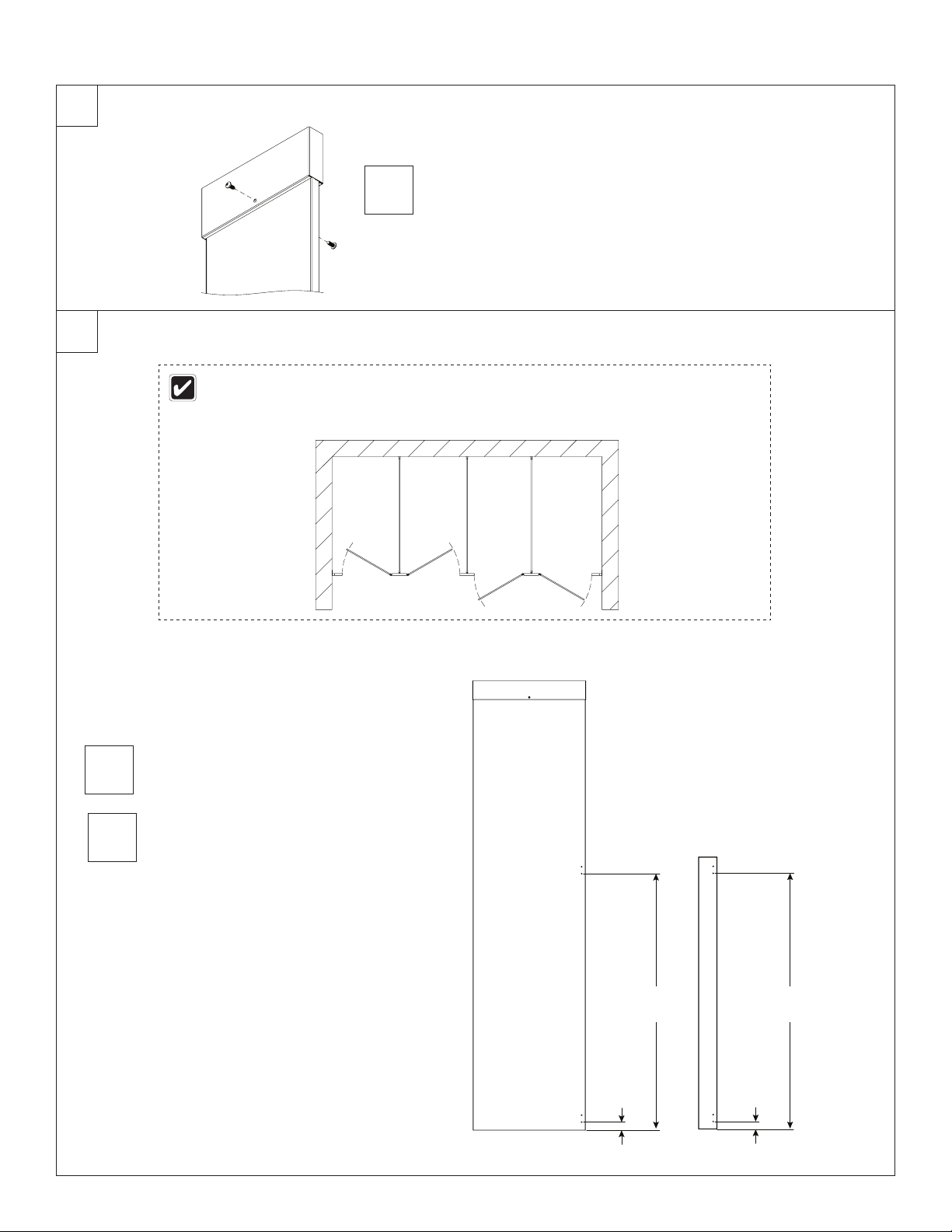

LC

L

C

L

C

L

"A"

"B"

"A1"

"B1"

*

"C"

*

"C"

C

L

*

"C"

C

L

*

"C"

*

"C"

C

LC

L

C

L

C

L

"A"

"B"

"A1"

"B1"

*

"C"

Panel

plumb line

Pilaster

plumb line

64"

(1626mm)

18" (457mm)

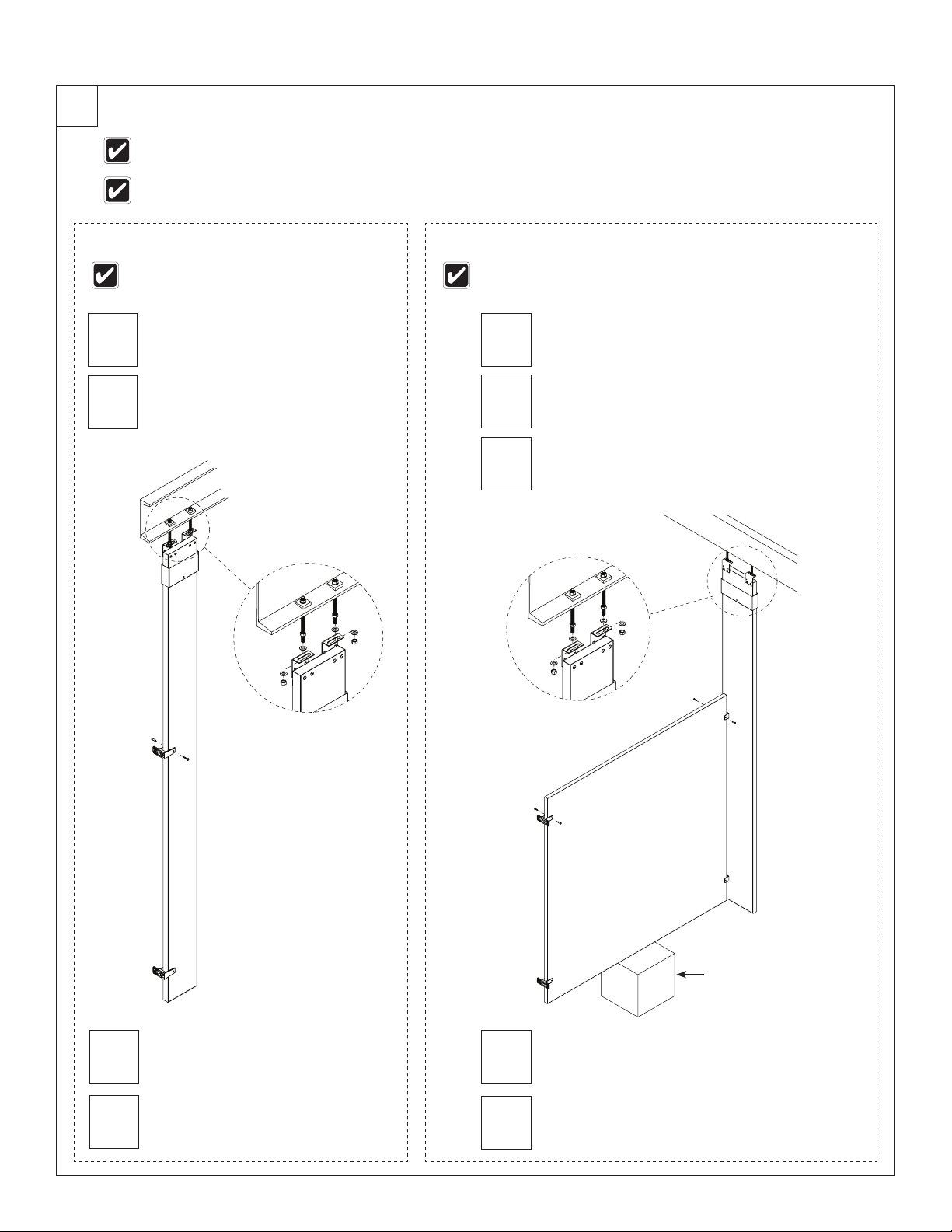

Pilaster centerline: Measure from

the back wall forward to the face of the

compartment, subtract ⁵⁄₈" (16mm) and

mark this location on the ceiling (“A”).

Mark the same measurement on the

opposite end of your layout (“A1”) and

draw a straight line connecting both

marks.

FOR FREESTANDING (FS)

PARTITIONS: Refer to submittal

drawings and determine the

approximate location of the outside

panels. Establish dimensions “A” and

“A1” as explained above.

A

Panel centerline: Measure the stall

width across the back wall and place

a mark at the top of the rear wall

(“B”). Repeat this step for each panel,

starting each measurement from the

last panel centerline (“B1”).

B

Panel

plumb line

Pilaster plumb line

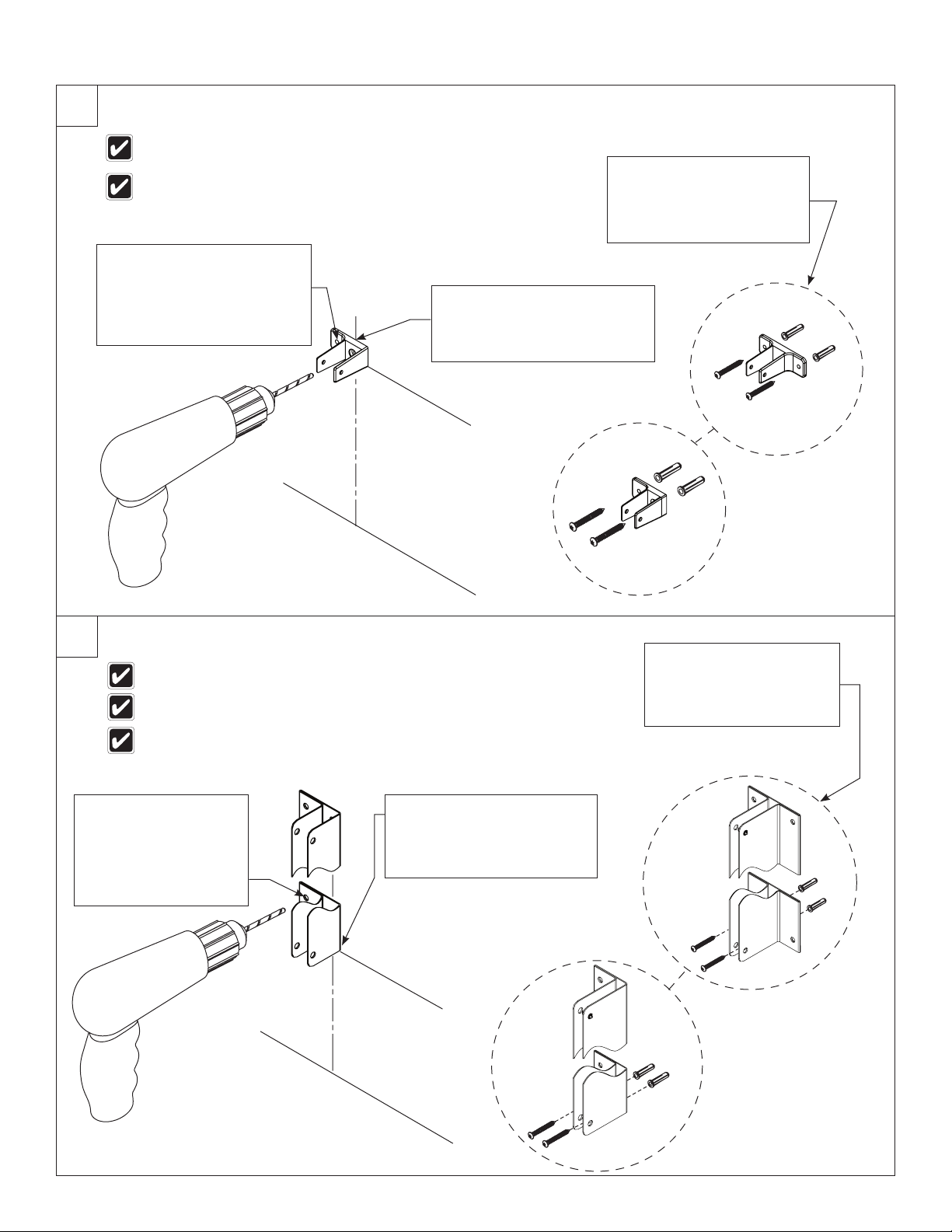

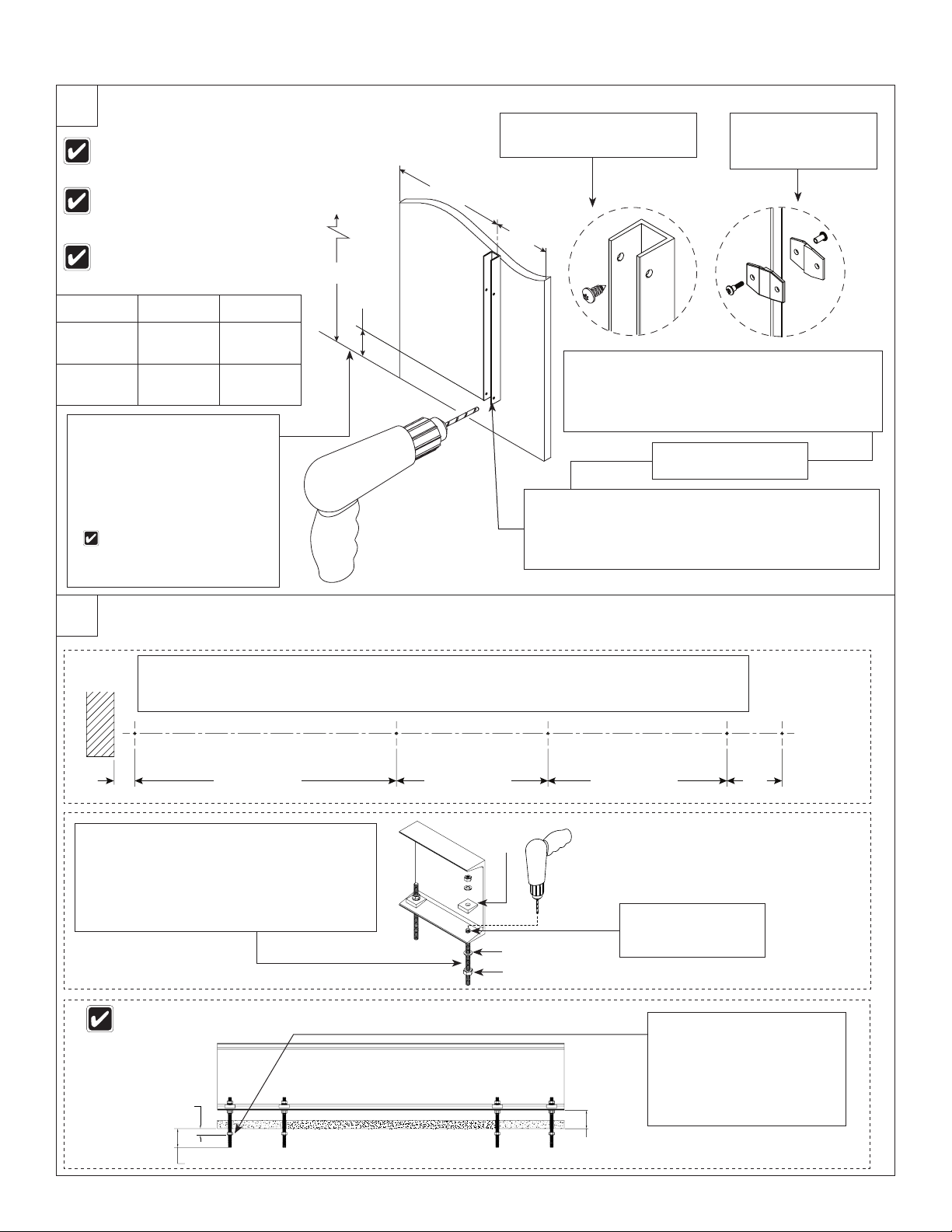

1a Layout Dimensions - Continuous Bracket (Optional)

Continuous brackets: Draw a plumb line on all walls from each

pilaster and panel centerline. From the highest point in the room,

measure 12½" (318mm) (for stainless steel) or 12¼" (311mm) (for

aluminum) from the floor and place a mark on the pilaster/panel plumb

line. Use a level to transfer that mark to all other plumb lines (“C”).

C