TABLE OF CONTENTS

Table of Contents

Section Page#

SECTION 1 – GETTING ACQUAINTED ________________________________________________4

SAFETY PRECAUTIONS ________________________________________________________________4

PACKAGING/SHIPPING ________________________________________________________________5

CONTENTS _________________________________________________________________________5

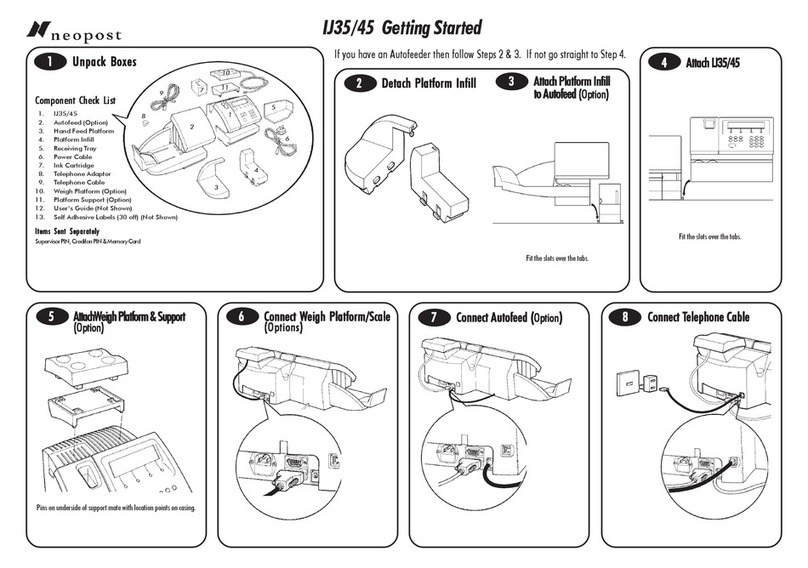

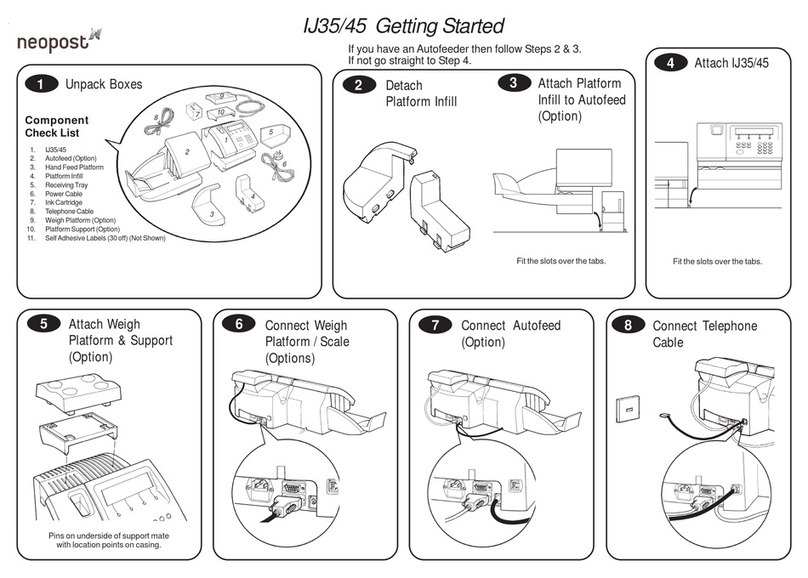

INITIAL ASSEMBLY___________________________________________________________________6

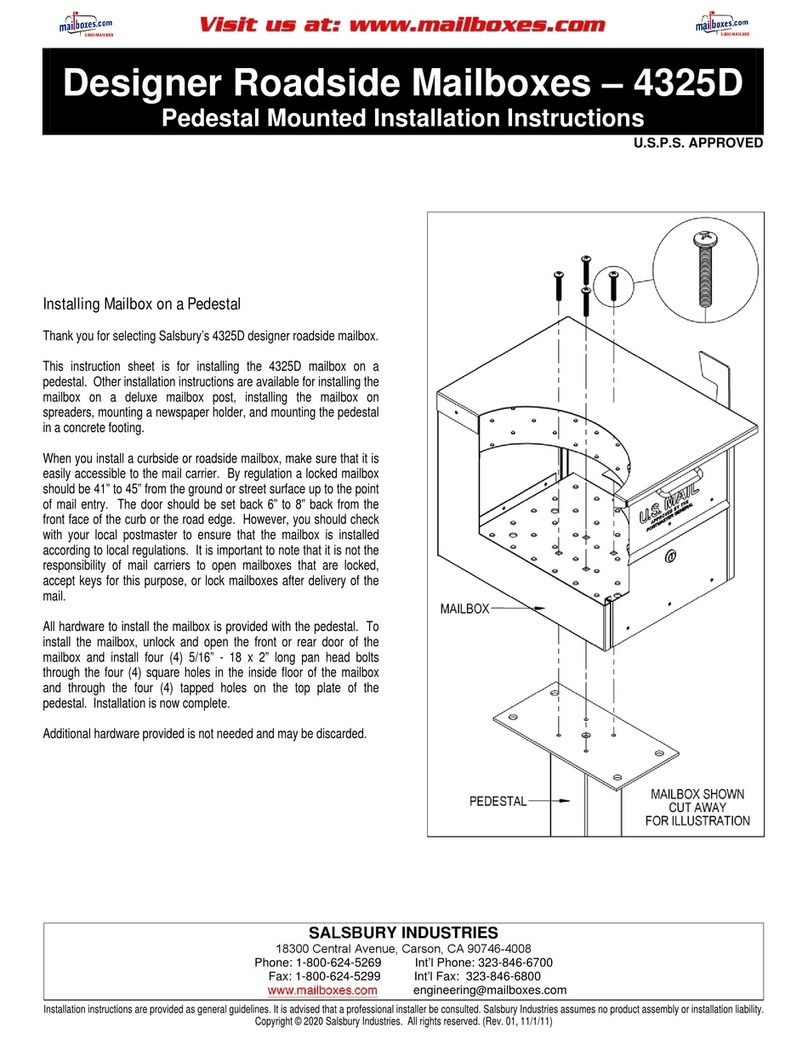

Attach the Print-Carriage Cover______________________________________________________6

Attach the Media Side Guides ________________________________________________________6

Attach the Rear Paper Support and Rear Media Guide ____________________________________7

SYSTEM REQUIREMENTS ______________________________________________________________7

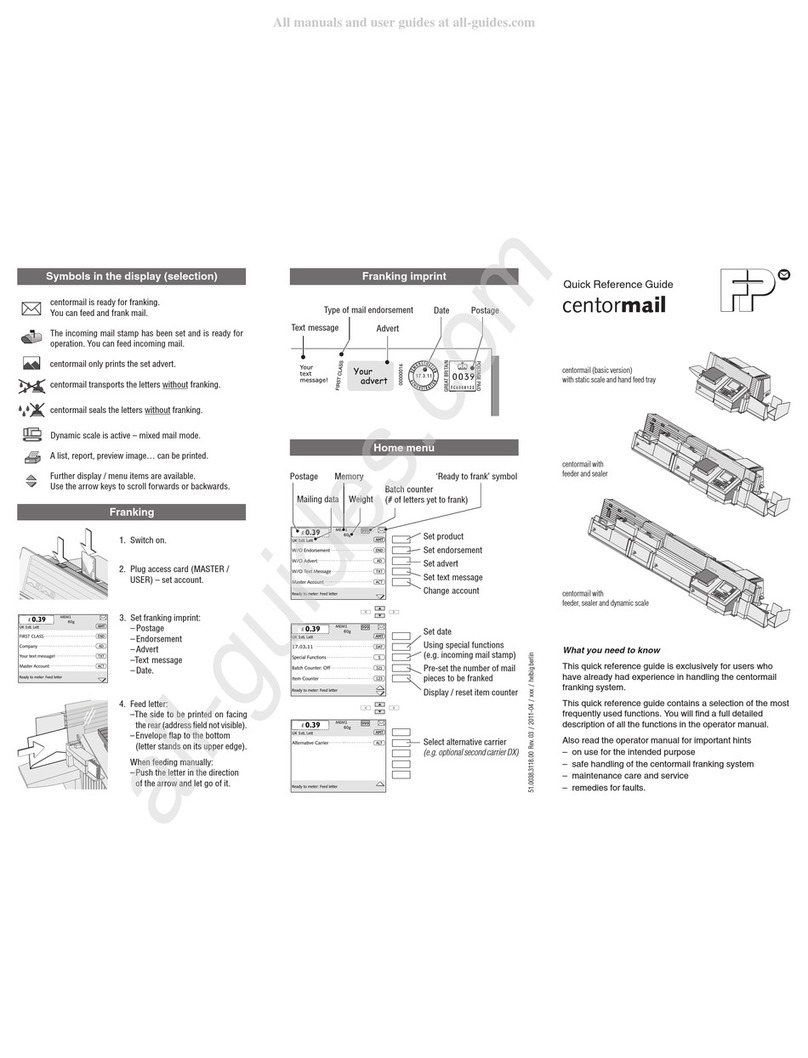

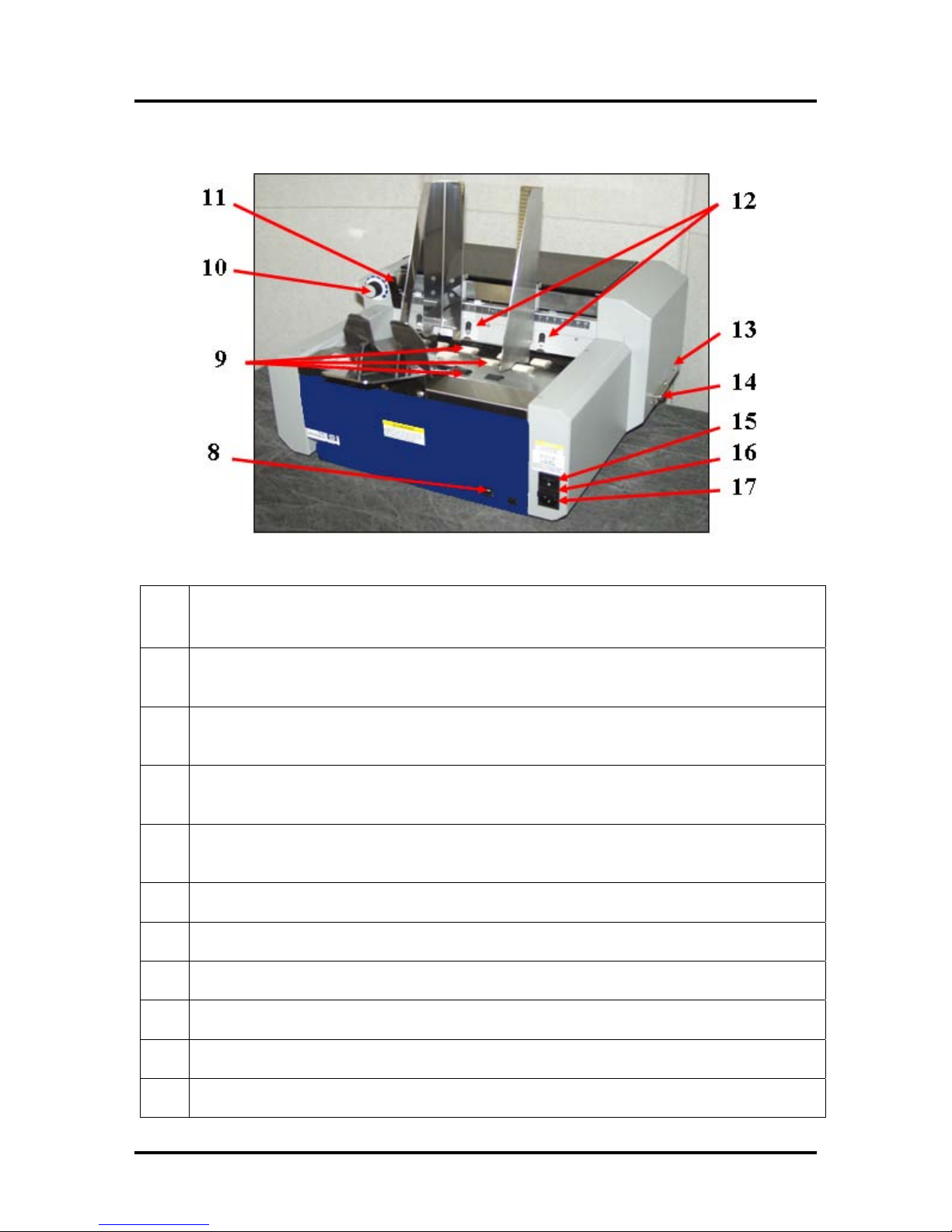

OPERATOR VIEW ____________________________________________________________________8

REAR VIEW ________________________________________________________________________9

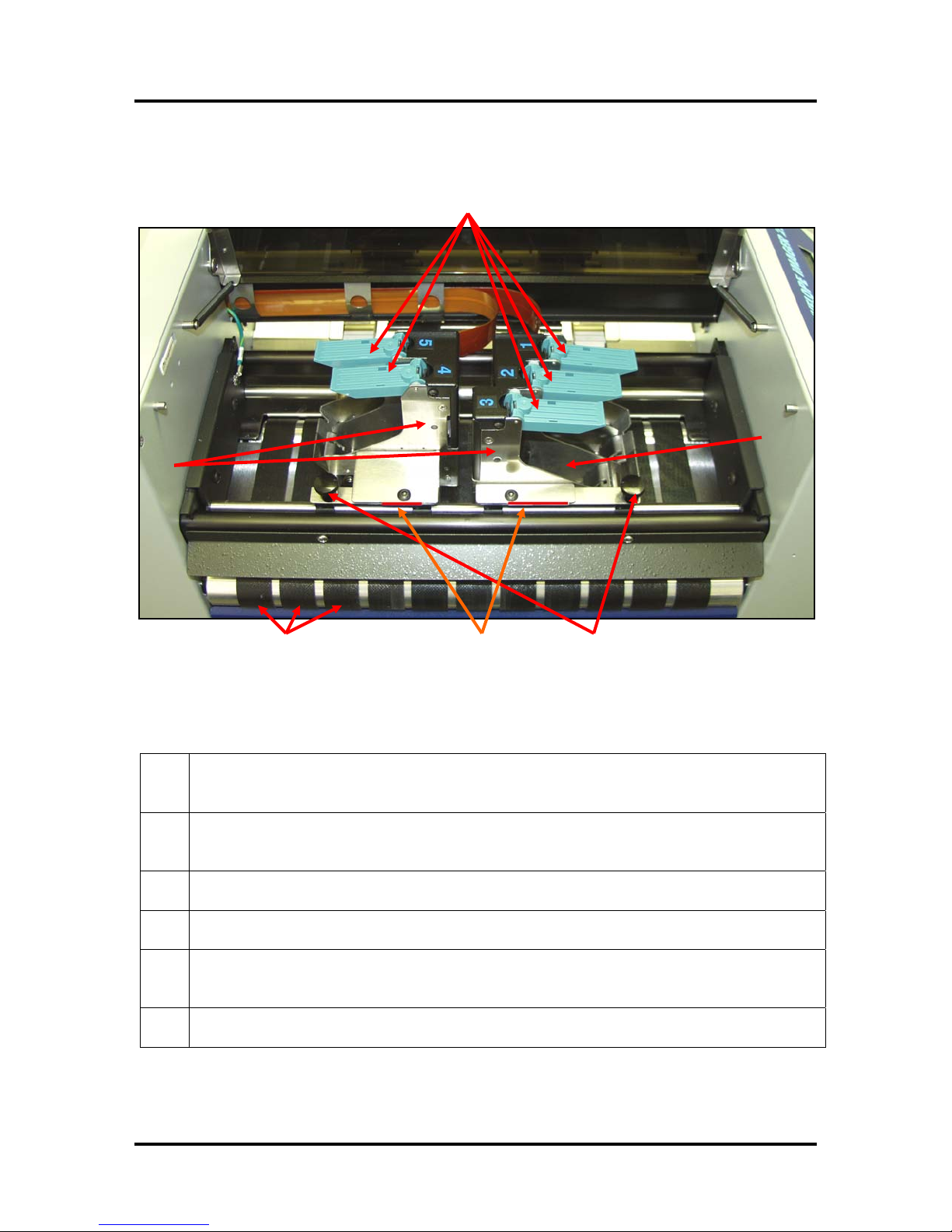

PRINT CARRIAGE VIEW ______________________________________________________________10

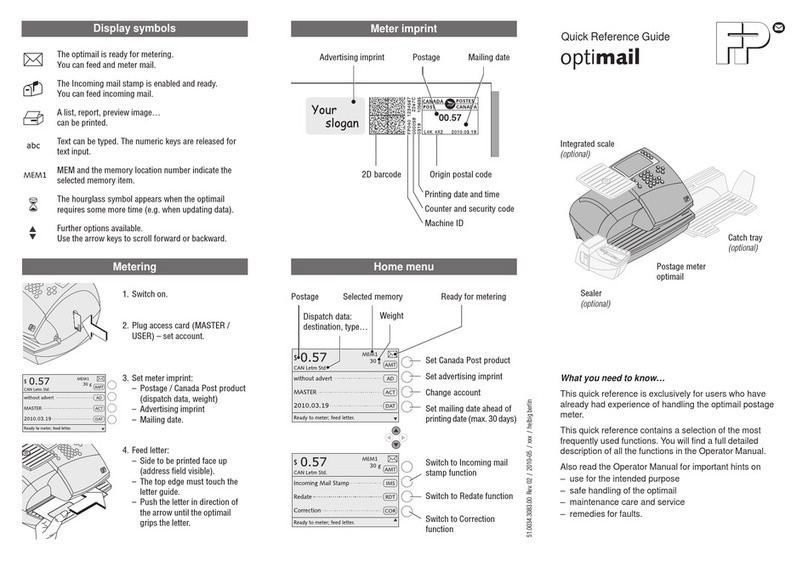

CONTROL PANEL ___________________________________________________________________ 11

SECTION 2 – PRINTER INSTALLATION AND SETUP __________________________________ 13

CHOOSE A LOCATION ________________________________________________________________ 13

CONNECTING POWER TO THE PRINTER ___________________________________________________ 13

CONNECTING TO THE COMPUTER _______________________________________________________ 13

INSTALLING THE INK CARTRIDGES______________________________________________________ 14

Ink Level Monitor Reset____________________________________________________________ 14

SETTING UP THE FEED SYSTEM ________________________________________________________ 15

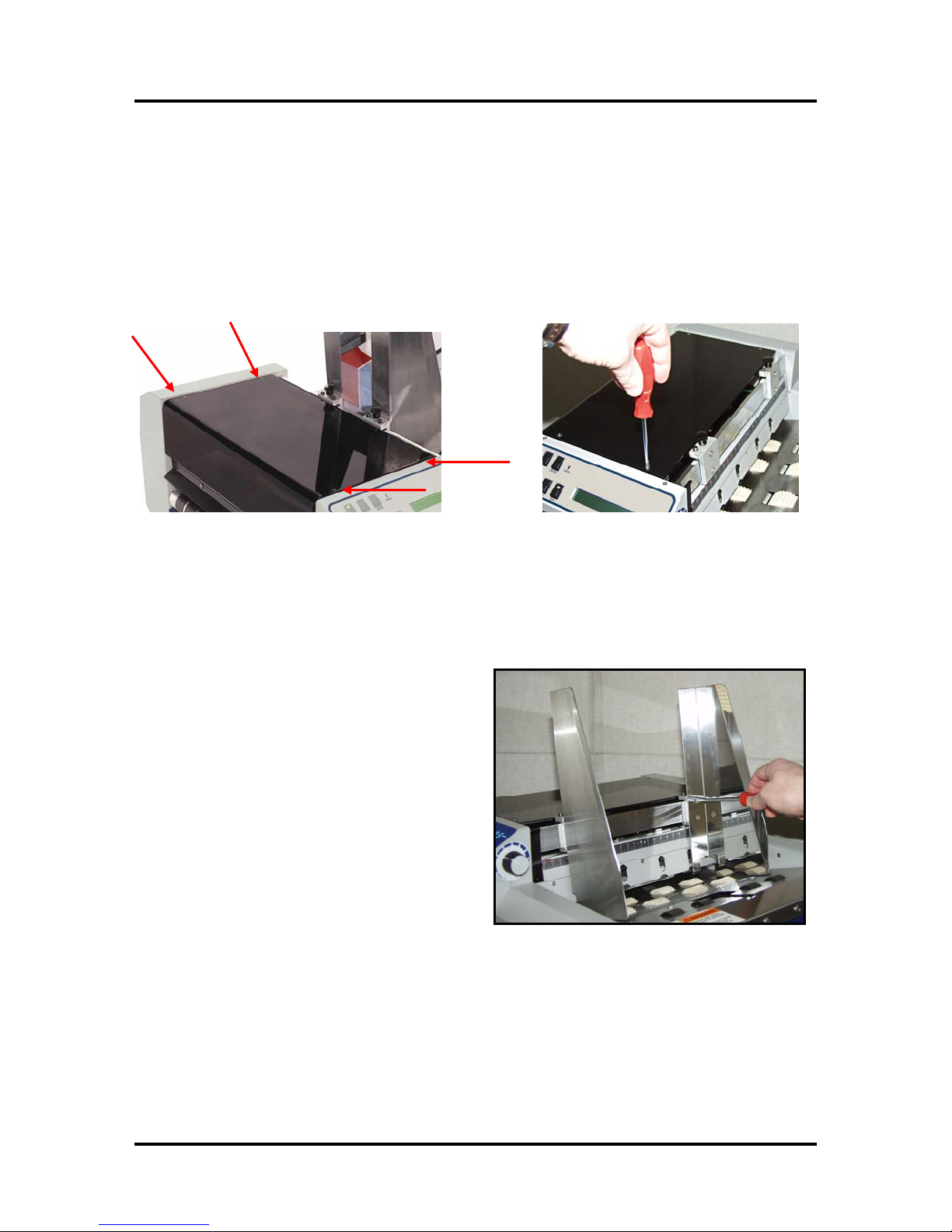

Sheet Separation Adjustment________________________________________________________ 15

Media Side Guide Adjustments ______________________________________________________ 16

Rear Media Guide Adjustments______________________________________________________ 16

Loading Media___________________________________________________________________ 17

Media Thickness Adjustment________________________________________________________ 18

PRINT UNIT POSITIONING (VERTICAL ADDRESS POSITIONING) ________________________________ 19

PAPER FEED (MEDIA TRANSPORT)TEST _________________________________________________20

TEST PRINT _______________________________________________________________________20

SECTION 3 – OPERATING THE PRINTER ____________________________________________ 21

PRINTER CONTROL PANEL &MENU FEATURES ___________________________________________ 21

PRINT RECOVERY AFTER A JAM________________________________________________________ 23

INSTALLING THE PRINTER DRIVER ______________________________________________________24

USB Port Selection and Verification Process____________________________________________28

Printer Driver Properties______________________________________________________30

Print Heads Tab (Head Adjustment) __________________________________________________30

SOFTWARE SETUP EXAMPLES _________________________________________________________32

Printing from Satori Bulk Mailer® 5.0 ________________________________________________32

Printing from Microsoft Word_______________________________________________________34

SECTION 4 – MAINTENANCE _______________________________________________________ 37

INKJET CARTRIDGE MAINTENANCE _____________________________________________________ 37

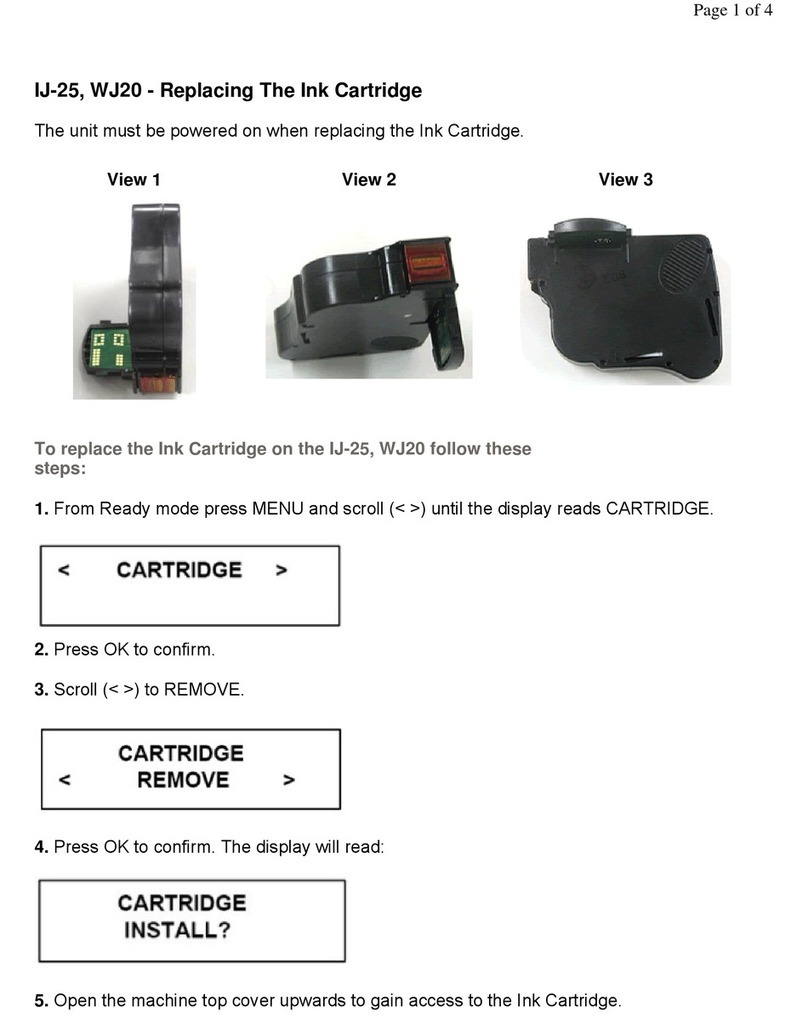

Replacing the Inkjet Cartridge:______________________________________________________ 37

Inkjet Cartridge Storage ___________________________________________________________ 38

Cartridge Disposal _______________________________________________________________ 38

Cleaning the Inkjet Cartridge (Printhead) _____________________________________________ 38

Limitations of this document: The information presented herein is subject to change. 10/14/2009 Neopost USA Inc. assumes no liability whatsoever

for any losses or damages resulting from use of this information. © 2009 Neopost USA Inc. All rights reserved.