August 30, 2012 PBI Internal use only 7

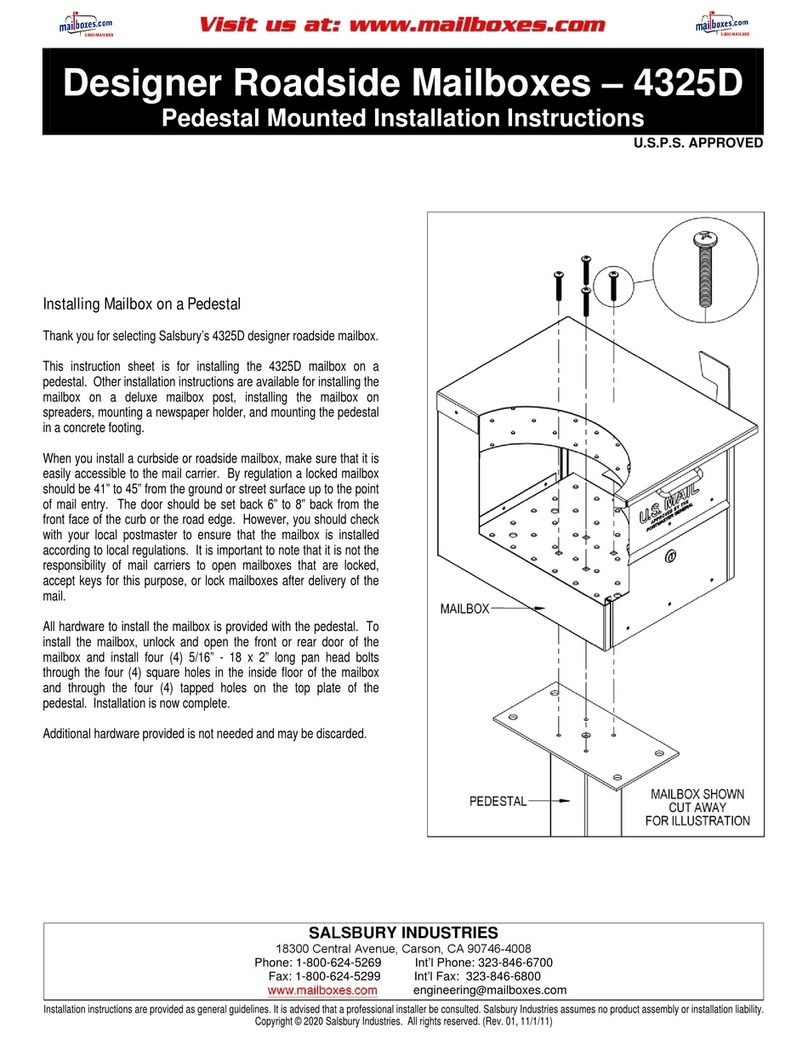

Stacks letters and flats

Height can be adjusted to match

the height of the letter and flats

output

Can be used with an exit transport

when stacking letters. (See Exit

Transport description on following

page)

OptiFlow Belt stacker. Stacks letters, flats

will drop into Drop Stacker (provided with

system).

OptiFlow Belt stacker. Stacks letters, flats

will drop into an Exist Transport (add on

option).

Simultaneous letters and flats OptiFlow

Tandem Belt Stacker stacks in tandem.

Single Belt Stacker will orient 3 ways

depending on the application

Letters Belt Stacking mounted onto Customer

Table with Flats drop stacker

Configuration

Simultaneous Letters & Flats Belt Stacking in

Tandem & mounted onto Customer Table.

Flats Belt Stacking mounted onto Customer Table

with Letters drop stacker or VPS

Letters Belt Stacking mounted onto Height

Adjustable Legs with Flats drop stacker

Simultaneous Letters & Flats Belt Stacking in Tandem

& mounted on Height Adjustable Legs

Flats Belt Stacking mounted onto Height Adjustable

Legs & Letters drop stacker or VPS

Letters Belt Stacking mounted onto Height

Adjustable Legs with SET

In-Line

Orientation

Tandem & In-Line

Tandem , In-Line

In-Line

Kits

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

Total Cost

F785800AAA

Manual Adjust Lift

F784801

240VAC Electronic Lift

F785800AAA

MANUAL ADJUST LIFT

F784801

240VAC Electronic Lift

Leg Type

KIT

BS05

KIT

BS06

KIT

BS04

KIT

BS03

KIT

BS02

KIT

BS01

Sales

kit No.

Not Required for IN-LINE

configuration

F785801AAA

Roller bridge for Right

Angled Belt Stacking

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F680

F680 Belt Conveyor Stacker

F680

F680 Belt Conveyor Stacker

2 x F680

F680 Belt Conveyor Stacker F785802AAA

2 x C Brackets for Tandem

Belt Stacking

Simulteneous Flats drop stacking not

advisable as Right Angled Front

configuration

F785803AAA

Sensor Bracket for

Flats Belt Stacking

2 x F680

F680 Belt Conveyor Stacker

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

Customers Own

Table

Customers Own

Table

or

F785800AAA

Manual Adjust

F680

F680 Belt Conveyor Stacker KIT

BS07

Right

Angled

Rear

Right

Angled

Front

Right Angled

Rear

Right Angled

Front

FOR 3 SERIES & NEXUS

DI350/400 & DI500/600 ONLY

In-Line

or

FOR DI800 & DI875 ONLY KIT

BS08

F785800AAA

Manual Adjust

F680

F680 Belt Conveyor Stacker

VARIOUS

F785900AAA COMPPRISING OF :

SWE47207 REAR SUPPORT

SWE47218 IN-LINE KIT

SWE470002 ENTRY GUIDE KIT

SWE47188 DOCKING PLATE

SWE471012 EXIT ROLLERS

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

KIT

BS09 F784802

100VAC Electronic Lift See pricing sheet

KIT

BS10 F784802

100VAC Electronic Lift See pricing sheet

KIT

BS12

KIT

BS11

See pricing sheet

See pricing sheet

F784800

120VAC Electronic Lift

F784800

120VAC Electronic Lift

Tandem Belt Stacker available

In-Line only

Letters Belt Stacking mounted onto Customer

Table with Flats drop stacker

Configuration

Simultaneous Letters & Flats Belt Stacking in

Tandem & mounted onto Customer Table.

Flats Belt Stacking mounted onto Customer Table

with Letters drop stacker or VPS

Letters Belt Stacking mounted onto Height

Adjustable Legs with Flats drop stacker

Simultaneous Letters & Flats Belt Stacking in Tandem

& mounted on Height Adjustable Legs

Flats Belt Stacking mounted onto Height Adjustable

Legs & Letters drop stacker or VPS

Letters Belt Stacking mounted onto Height

Adjustable Legs with SET

In-Line

Orientation

Tandem & In-Line

Tandem , In-Line

In-Line

Kits

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

Total Cost

F785800AAA

Manual Adjust Lift

F784801

240VAC Electronic Lift

F785800AAA

MANUAL ADJUST LIFT

F784801

240VAC Electronic Lift

Leg Type

KIT

BS05

KIT

BS06

KIT

BS04

KIT

BS03

KIT

BS02

KIT

BS01

Sales

kit No.

Not Required for IN-LINE

configuration

F785801AAA

Roller bridge for Right

Angled Belt Stacking

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F680

F680 Belt Conveyor Stacker

F680

F680 Belt Conveyor Stacker

2 x F680

F680 Belt Conveyor Stacker F785802AAA

2 x C Brackets for Tandem

Belt Stacking

Simulteneous Flats drop stacking not

advisable as Right Angled Front

configuration

F785803AAA

Sensor Bracket for

Flats Belt Stacking

2 x F680

F680 Belt Conveyor Stacker

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

Customers Own

Table

Customers Own

Table

or

F785800AAA

Manual Adjust

F680

F680 Belt Conveyor Stacker KIT

BS07

Right

Angled

Rear

Right

Angled

Front

Right Angled

Rear

Right Angled

Front

FOR 3 SERIES & NEXUS

DI350/400 & DI500/600 ONLY

In-Line

or

FOR DI800 & DI875 ONLY KIT

BS08

F785800AAA

Manual Adjust

F680

F680 Belt Conveyor Stacker

VARIOUS

F785900AAA COMPPRISING OF :

SWE47207 REAR SUPPORT

SWE47218 IN-LINE KIT

SWE470002 ENTRY GUIDE KIT

SWE47188 DOCKING PLATE

SWE471012 EXIT ROLLERS

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

See pricing sheet

KIT

BS09 F784802

100VAC Electronic Lift See pricing sheet

KIT

BS10 F784802

100VAC Electronic Lift See pricing sheet

KIT

BS12

KIT

BS11

See pricing sheet

See pricing sheet

F784800

120VAC Electronic Lift

F784800

120VAC Electronic Lift

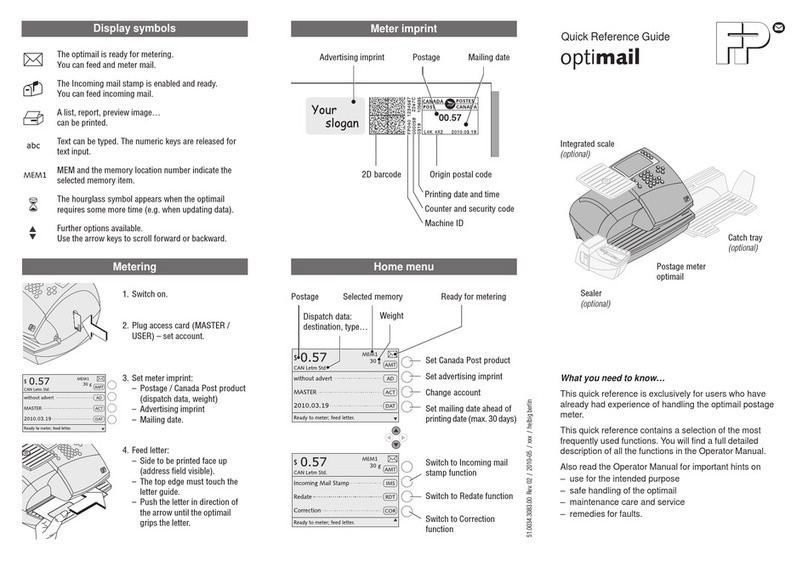

Configuration Considerations

OptiFlow Belt Stacker

OptiFlow Tandem Stacker

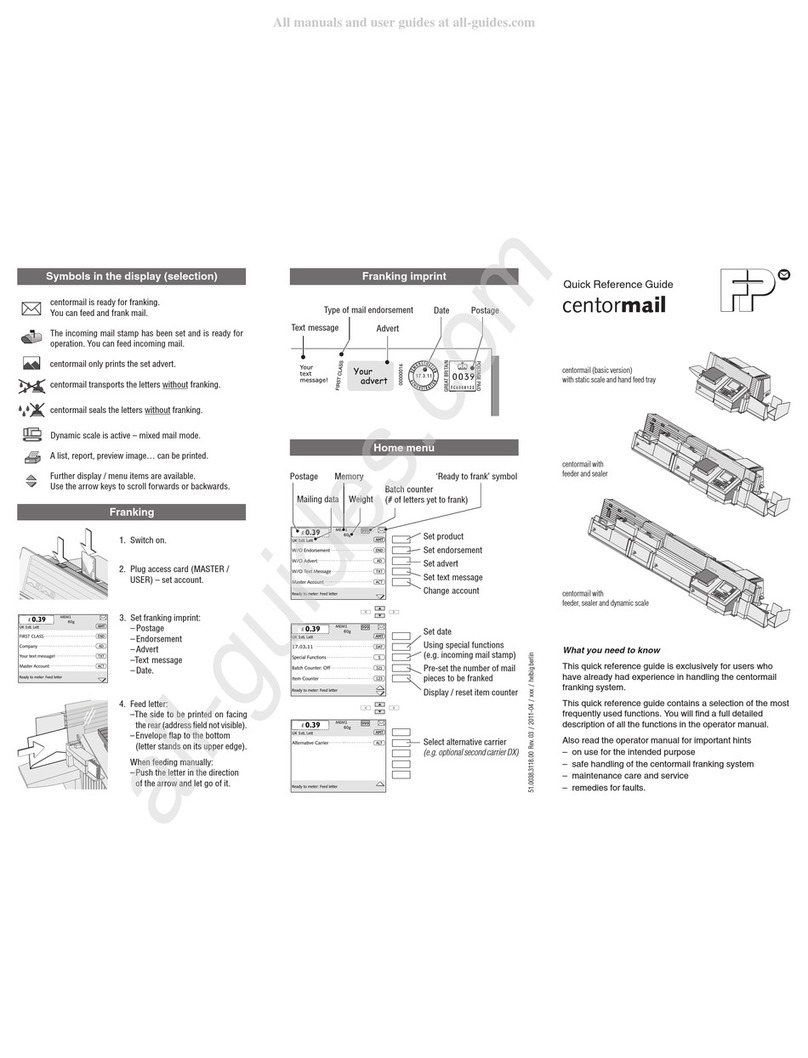

The OptiFlow Belt Stacker can be used to stack letters in Right Angled or In-Line

configurations with the Di900/950 inserters. In Line mode is required for running

“Flats”.

The OptiFlow Tandem Stacker allows for the stacking of “Letters” and “Flats”

simultaneously. The Stacker consists of two stacker units mounted onto one set of

legs or one table at the correct vertical spacing to receive “Letters” and “Flats”

output from the Inserter. In Line mode is required for running “Letters” and “Flats”

simultaneously. The stacker can be placed on the height adjustable DI950 table

eliminating the need for the dedicated stacker table.

(Letters or Flats)