Content

1. SPECIFICATIONS..............................................................................................................3

2. TRANSPORT .....................................................................................................................5

2.1

Load..........................................................................................................................5

2.2

Packaging .................................................................................................................5

2.3

Logistics....................................................................................................................5

2.4

Warnings!..................................................................................................................5

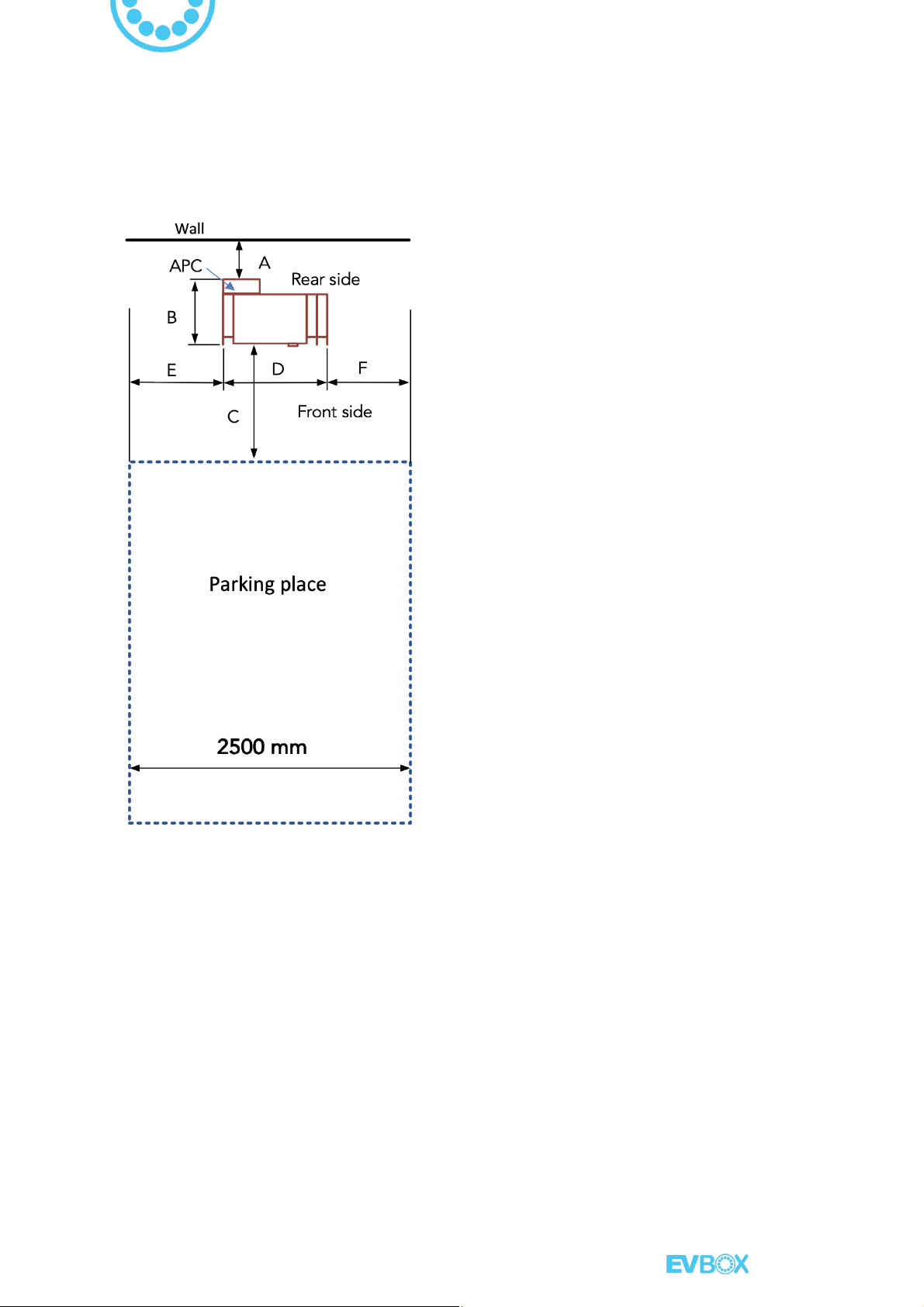

3. CIVIL ENGINEERING ........................................................................................................6

3.1

Charger positioning (without Auxiliary power cabinet – APC) .................................6

3.2

Charger positioning (with Auxiliary power cabinet – APC).......................................7

3.3

Charger installation on site.......................................................................................8

3.3.1 Installation with Mounting kit (recommended option): ........................................8

3.3.2 Charger foundations WITHOUT Auxiliary power cabinet (APC):..........................9

3.3.3 Preparing and installing the charger WITHOUT Auxiliary power cabinet (APC):11

3.3.4 Charger foundations WITH Auxiliary power cabinet (APC): ...............................14

3.3.5 Preparing and installing the charger WITH Auxiliary power cabinet (APC):.......14

3.3.6 Installation directly with chemical anchor: * .......................................................17

4. ELECTRICAL GRID CONNECTION ................................................................................18

4.1

Electrical connection for charger without storage..................................................18

4.2

Electrical connection for charger with storage .......................................................19

4.3

Passage of the input cables....................................................................................19

4.4

Special attention should be paid to the ground cable...........................................20

4.5

Special attention to the need for a surge arrester..................................................20

5. COMMISSIONING..........................................................................................................21

5.1

Opening procedure locks:

...................................................................................... 21

5.2

Charger restart procedure without battery

............................................................22

6. APPENDIX 1:...................................................................................................................23

Connection grid terminal block..............................................................................................23

7. APPENDIX 2:...................................................................................................................25

Cables passage ......................................................................................................................25

8. APPENDIX 3:...................................................................................................................27

Dimensions.............................................................................................................................27

9. APPENDIX 4:...................................................................................................................29

Connection terminals details: power and communication.....................................................29

10. APPENDIX 5: ..............................................................................................................32

COMMISSIONING VALIDATION REPORT ............................................................................32