ESPT JARUEN DE KO

98107

8

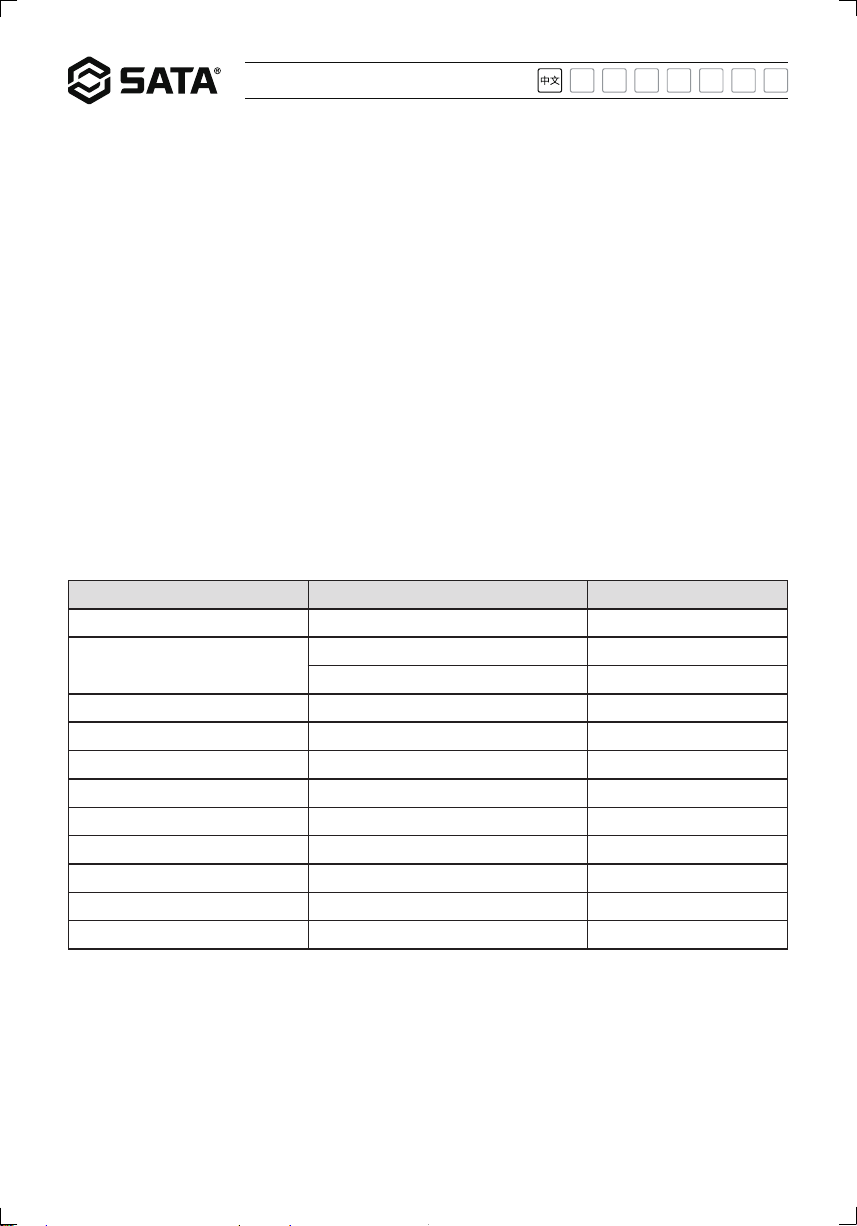

2. 单位转换:

1. 按" " 一次,[ 功能设置 ] 图标点亮,当前使用单位闪烁

2. 按"-" 或"+" 选择需要使用的单位,3 秒后自动保存

说明:初始单位为 Bar,另有三种单位可选:Psi / KPa / Kg / cm2

3. 充气压力设置:

1. 按一次快捷键 " ",显示该快捷键当前的预设压力值

2. 按+/- 键调整目标压力值

3. 按" " 确认

4. 目标压力值保存到该快捷键上

5." "、" " 设置方法相同

4.[OPS] / [ 新胎过充 ] 功能:

1. 按" " 两次 , [ 新胎过充 ] 图标在屏幕上闪烁

2. 按"-" 或"+" 选择希望增加的过充值,3 秒后自动保存

3. 正确设置过充值后,[ 新胎过充 ] 图标将在屏幕上显示

4. 长按 " " 不放,直到充气夹头出气,将夹头与气门芯连接

5. 蜂鸣器发出“嘀嘀”声,充气完毕,拔下气门嘴夹头

6. 若需关闭过充功能,将过充值设为 0 即可

特别说明:

[OPS] / [ 新胎过充 ] 是给第一次充气的新轮胎使用的过充功能,以使轮胎与轮毂配合紧密

过充值等于最大胎压(MAX.PRESSURE)减标准胎压,例如 350KPa(51Psi) MAX.PRESSURE 的新胎,最大胎压为 3.5Bar,在标准

胎压为 2.5Bar 的情况下,过充值应设定为 3.5Bar-2.5Bar=1Bar

*1Bar=100KPa;1Psi=6.89KPa;1Bar=1.02 Kg/cm

5. 强充功能:

1. 根据需要设定充气目标压力值

2. 长按 " " 不放,直到充气夹头出气,将夹头与气门芯连接

说明:当设备检测到的胎压低于 0.2Bar,即默认未与轮胎连接,不启动自动充气功能

强充功能帮助解决轮胎更换后,轮胎与轮毂间处于不密封,胎压低于 0.2Bar 时的充气

6. LED 功能:

按三次 " ",屏幕显示 LON,按+/- 键,即可开关照明功能

显示 LON 表示 LED 灯打开;显示 LOFF 表示 LED 灯关闭

设备开启后,默认设定 LED 自动开启

7. 卷管气操作:

拉伸操作:

1. 将管线缓慢拉伸至所需长度,靠棘轮制动阀来锁定。如未能有效锁止,请继续慢慢拉出 6-40cm,即可锁定。注意:拉伸时,

请用 1.5-4 Kg 的力即可,不要超过此力硬拉,及超出管线的界限警示线

回收操作:

1. 先慢慢拉出 6-40cm,使棘轮制动阀处于脱锁状态

2. 用手稳住管线,让其依靠弹簧回收力慢慢回收

98107 立式轮胎充气机-8国-200615.indd 898107 立式轮胎充气机-8国-200615.indd 8 2020/6/23 12:38:362020/6/23 12:38:36